Mold positioning and calibrating device

A technology of calibrating device and die plate, applied in metal processing and other directions, can solve the problems of damaged cutter, inability to complete cutting, and very high requirements on die plate positioning accuracy, and achieve the effect of protecting safe life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

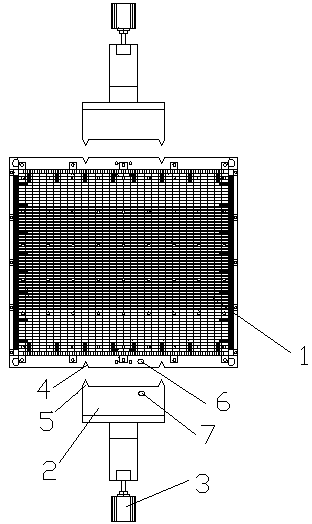

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, a mold plate positioning and calibration device includes positioning plates 2 arranged on both sides of the mold plate 1 in the traveling direction, and at least one bump 5 is provided on the end surface of the positioning plate 2 close to the mold plate 1 , The two sides of the mold plate 1 are provided with grooves 4 that are consistent with the number and shape of the bumps 5 .

[0014] When the mold plate walks to the cutter station, by moving the positioning plate 2, the protrusion 5 is inserted into the groove 4, so as to guide the error of the mold plate 1 at the cutter station and ensure that the mold plate 1 is completely in the cutting position. On the knife station, the safety life of the cutting knife is protected to the greatest extent when cutting.

[0015] Wherein, the bump 5 has a triangular shape, which not only faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com