Guide device and method for metal polar plate of fuel cell

A metal plate and fuel cell technology, which is applied to fuel cells, uses electrical devices, measuring devices, etc., can solve the problems of reducing the power density of fuel cell stacks, increasing the width of the sealing structure, and consuming a lot of manpower and material resources, and achieves a simple structure. , The effect of preventing virtual contact and avoiding rubbing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

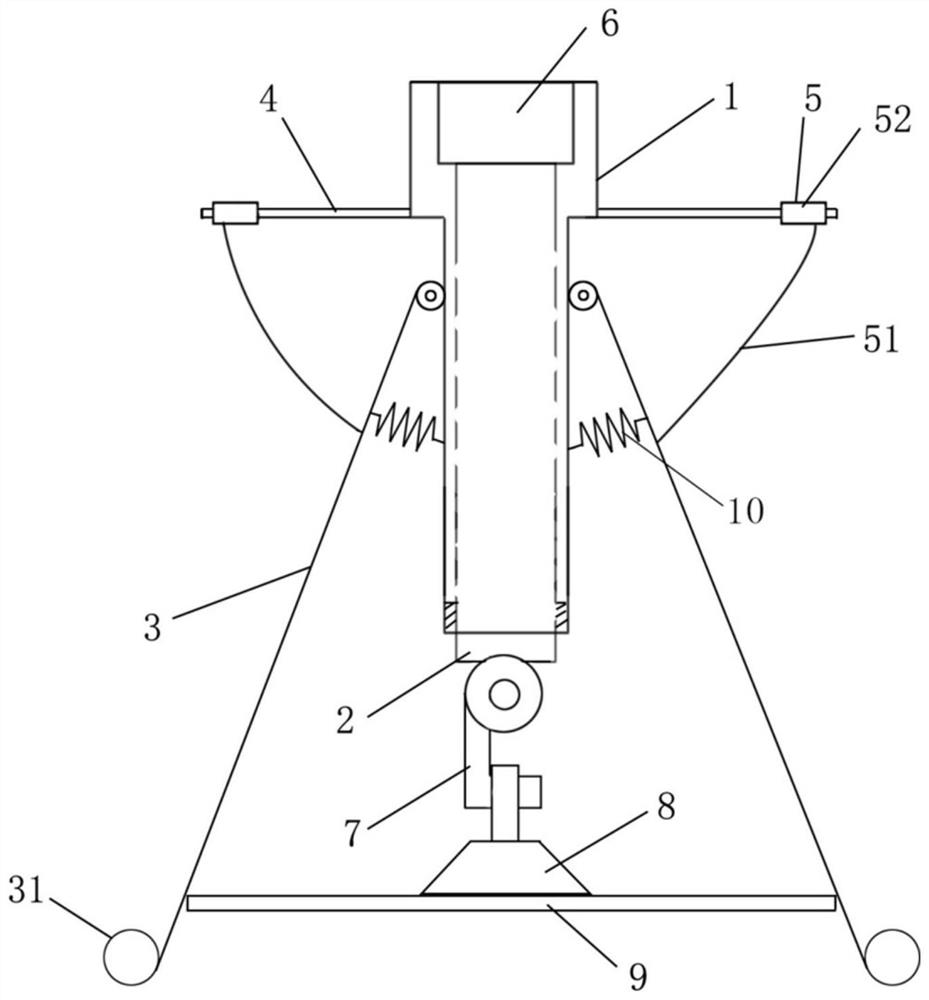

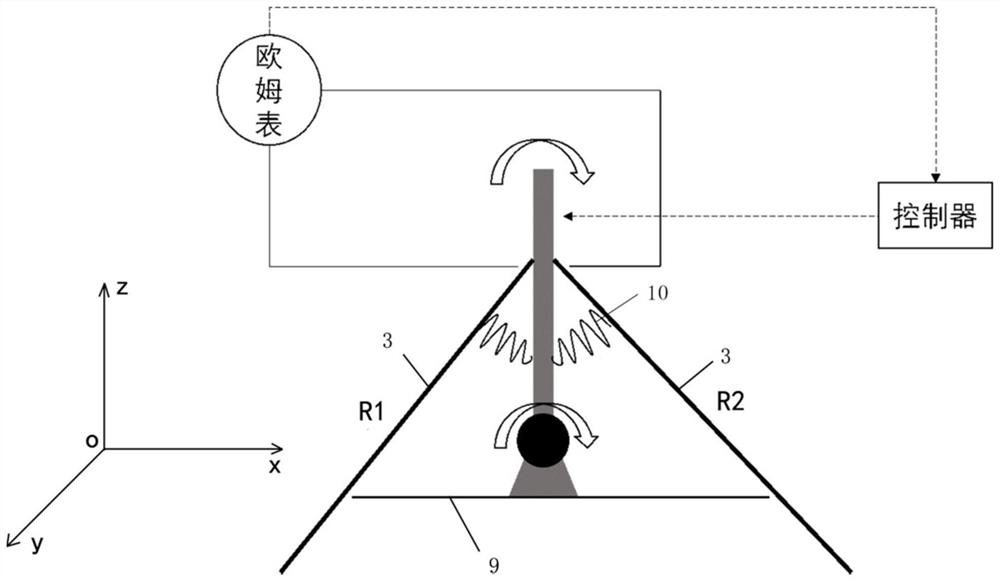

[0032] Such as figure 1 As shown, this embodiment provides a straightening device for a metal plate of a fuel cell, including a grasping module, an attitude adjustment module and a measurement module.

[0033] The gripping module includes a vacuum chuck 8 and metal connectors (not shown in the figure). The vacuum chuck 8 is used to grab the metal pole plate 9 . The metal connector is arranged on one side of the vacuum chuck 8, and when the vacuum chuck 8 sucks the metal pole plate 9, the metal pole plate 9 contacts the metal connector.

[0034] The measurement module includes a hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com