Treatment technology and equipment for biological fermentation fungus residue drying flue gas stink

A biological fermentation and flue gas technology, applied in gas treatment, air quality improvement, chemical instruments and methods, etc., to avoid trouble, solve the odor of flue gas, and save floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

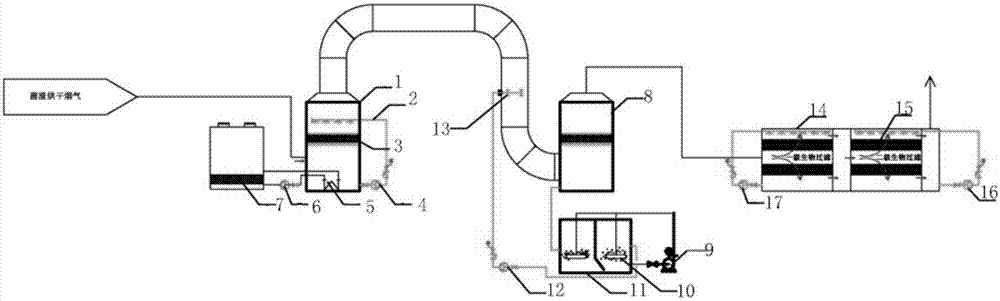

[0023] The specific implementation method of the present invention will be described below in conjunction with the accompanying drawings.

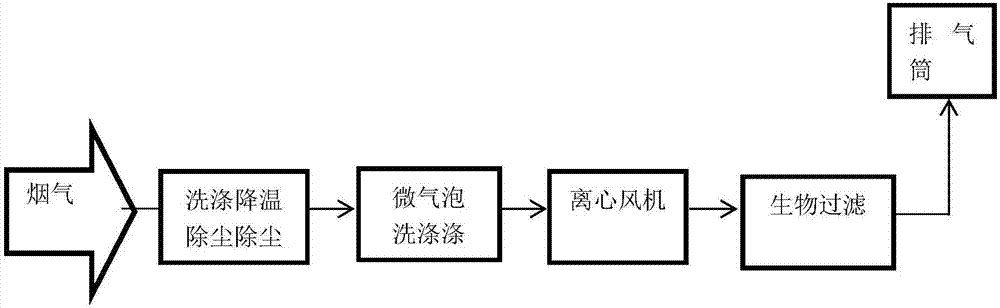

[0024] like Figures 1 to 5 As shown, the present invention is completed by three sections, namely three sets of main equipment and its auxiliary equipment constitute a complete set of system equipment, to achieve the goal of solving the odor of smoke. They are dedusting cooling tower and its auxiliary equipment, micro-bubble washing tower and its auxiliary equipment, biological filtration tower and its auxiliary equipment. Among them, the dedusting and cooling tower 1 and the micro-bubble washing tower are used for cooling, dust removal and oil removal, laying the foundation for the deodorization of the biological filter tower 14, ensuring a suitable temperature, and avoiding the blocking of the biological filter tower 14 by dust and tar.

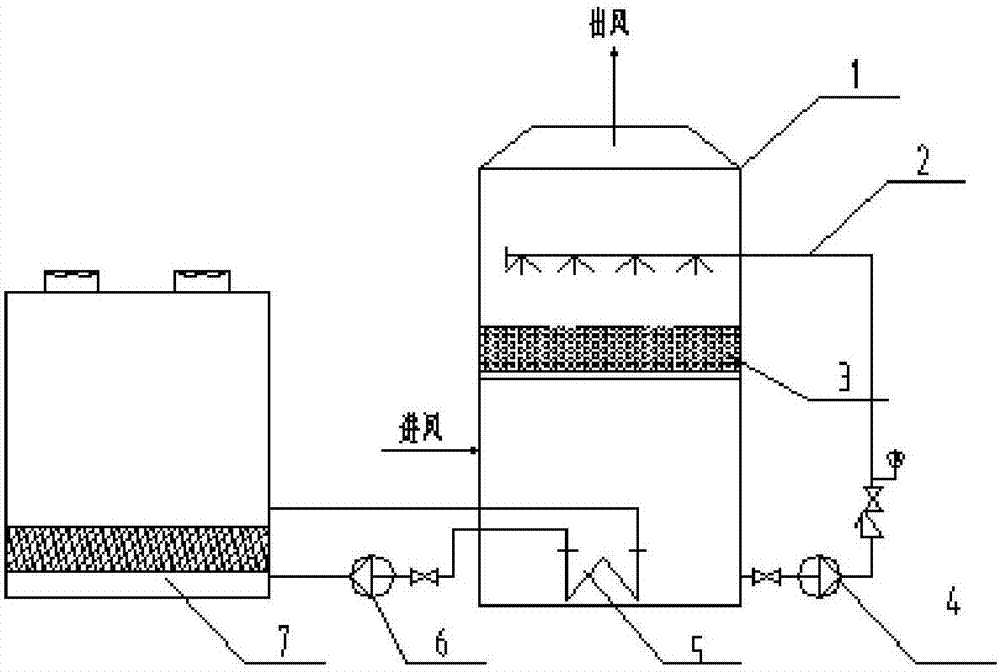

[0025] Dust removal and cooling tower 1: The dust removal and cooling tower 1 is provided with a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com