Rotator cuff patch

A patch and rotator cuff technology, applied in the field of patch for treating rotator cuff injury, can solve the problems of biomechanical strength, histocompatibility, safety of material sources, cost limitation, etc., and achieve novel structural design and avoid patch creep. Changeable, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

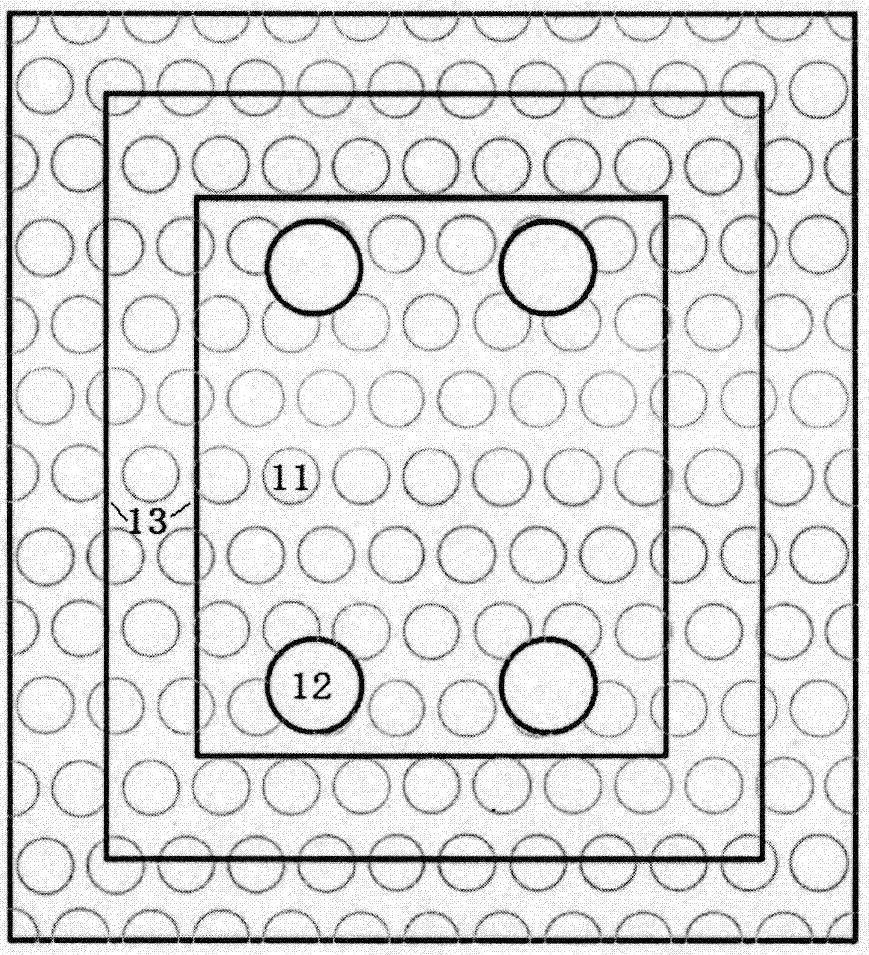

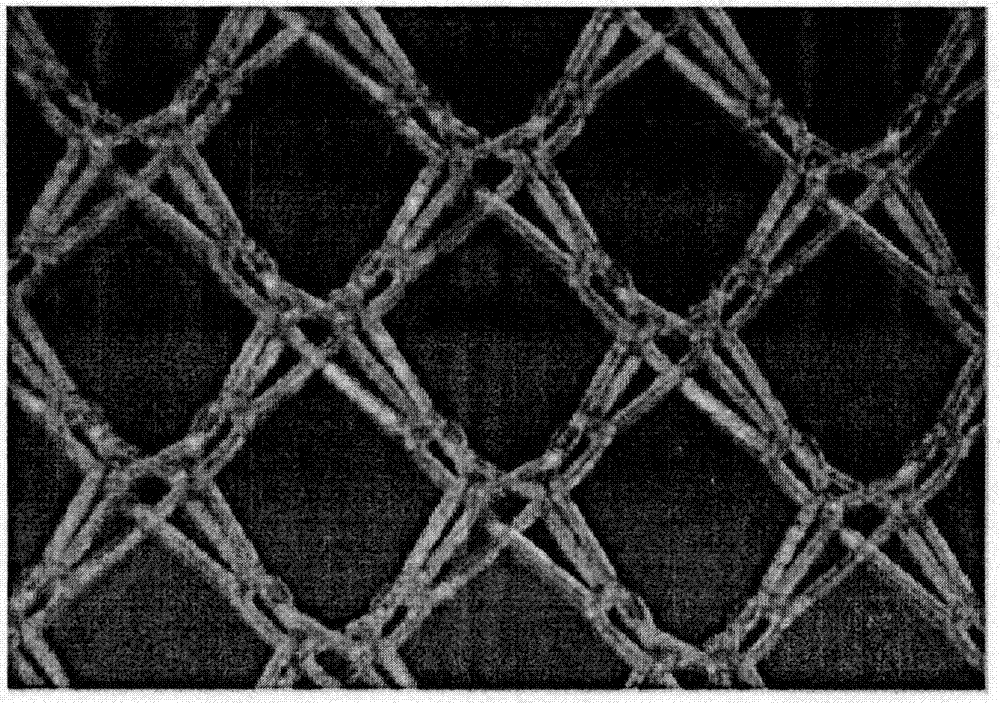

[0032] Using polypropylene monofilament fiber as raw material, after warping, it is designed to change the warp and satin structure, with two combs, one thread and one empty symmetrical lap yarn, and the fabric weaving parameters are set to GB1: 1-0-1 / 1-2-2 / 2- 3-2 / 2-1-1 / / ; GB2: 2-3-2 / 2-1-1 / 1-0-1 / 1-2-2 / / , the warp knitting holes of the obtained gray cloth are rhombus ( figure 2 ), the side length of the rhombus is 3mm. The warp knitting large hole and the dividing line are also woven and formed on the warp knitting machine. The diameter of the warp knitted large hole is 5mm. Finally, the final product is obtained after shaping.

Embodiment 2

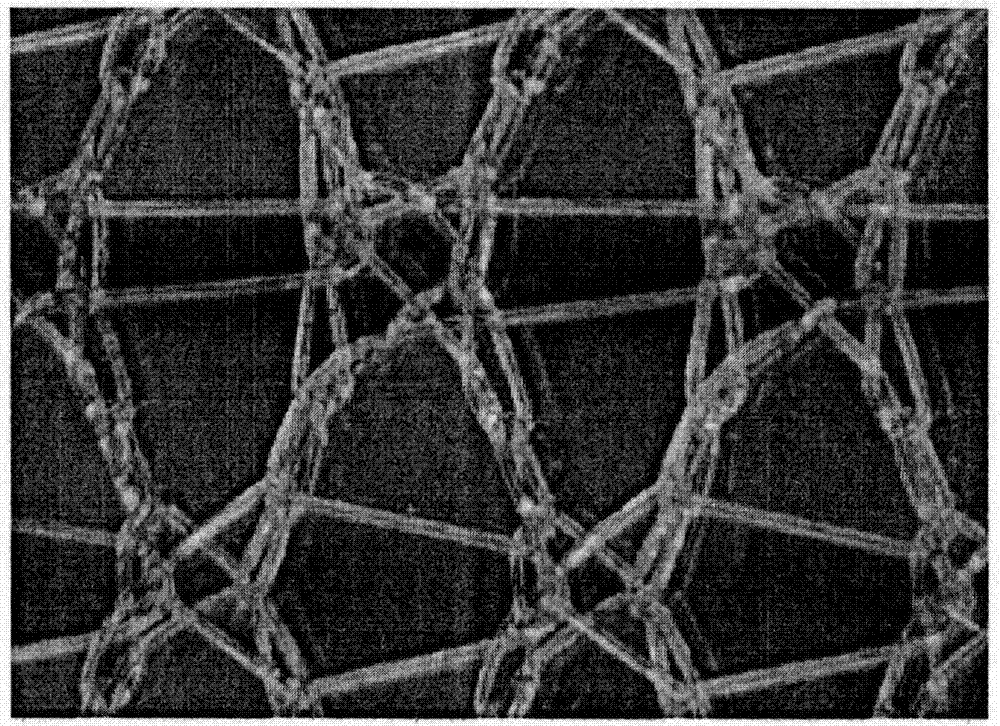

[0034] The same method described in Example 1 was used to make the rotator cuff patch ( image 3 ), only add a third bar for weft insertion when weaving.

Embodiment 3

[0036] The rotator cuff patch ( Figure 4 ), only adjust the fabric weaving parameters to GB1: 1-0-1 / 1-2-2 / 2-1-2 / 2-3-2 / 2-1-1 / 1-2-1 / / ; GB2: 2-3-2 / 2-1-2 / 2-3-2 / 2-0-1 / 1-2-1 / 1-0-1 / / .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com