Energy-saving graphite heat exchanger utilizing methane chloride for achieving synthesis of heat energy and production method

A technology of graphite heat exchanger and monochloromethane, which is applied in the direction of heat exchanger, heat exchanger shell, indirect heat exchanger, etc., can solve the problem of heat not being recycled, and reduce the use of steam or other heat sources and reduce the use of , the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

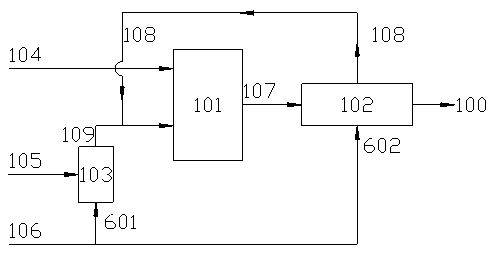

Problems solved by technology

Method used

Image

Examples

Embodiment 1

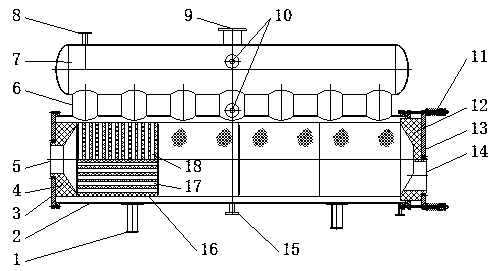

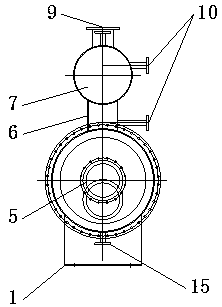

[0036]In the gas-phase monochloromethane production using solid alumina as a catalyst, the reaction gas at a temperature above 200° C. from the monochloromethane synthesis reactor 101 enters the transverse hole 17 of the graphite heat exchange block 16 of the present invention, and graphite can be exchanged for The methanol in the longitudinal hole 18 of the heat block 16 is heated and vaporized and reaches a pressure above 0.2 MPa, and then is supplied to the chloromethane synthesis reactor.

Embodiment 2

[0038] In the liquid-phase monochloromethane production using zinc chloride as a catalyst, the reaction gas at a temperature above 110° C. from the monochloromethane synthesis reactor 101 enters the transverse hole 17 of the graphite heat exchange block 16 of the present invention, and the graphite can be The methanol in the longitudinal hole 18 of the heat exchange block 16 is heated and vaporized and reaches a pressure above 0.05Mpa, and then is supplied to the chloromethane synthesis reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com