Modular pressure-bearing heat pump system and control method thereof

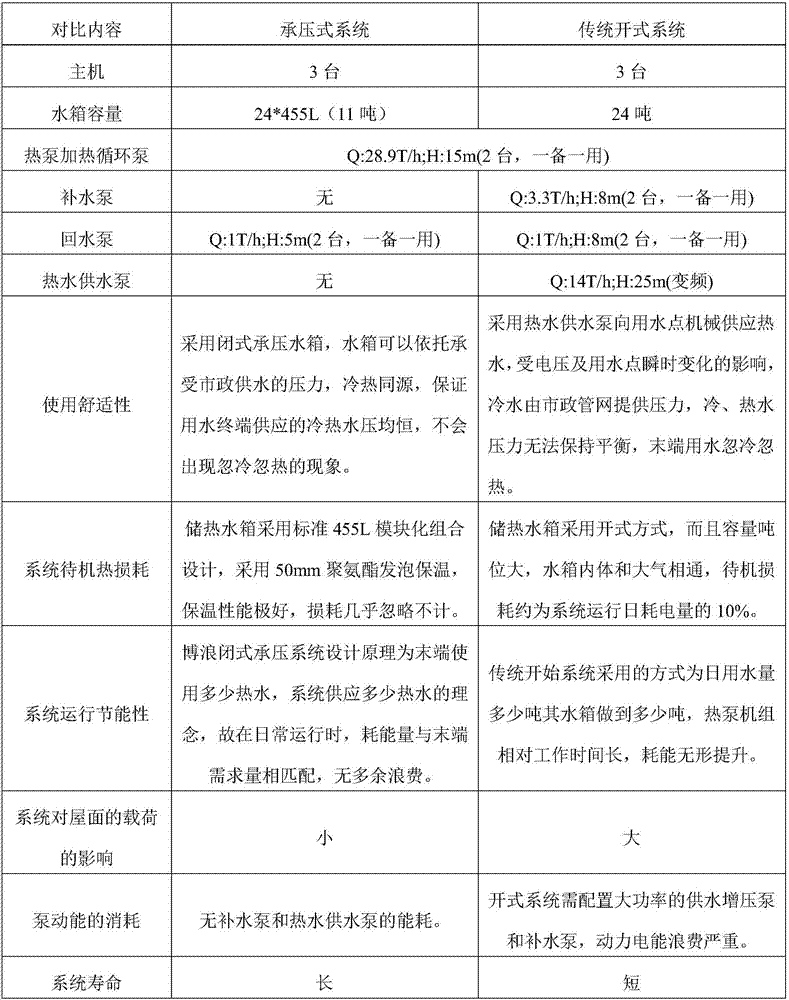

A heat pump system and modular technology, applied in solar heating systems, heating devices, fluid heaters, etc., can solve the problems of unbalanced hot water supply pressure, large capacity tonnage, large standby loss, etc., to prevent water temperature fluctuations, The effect of low comprehensive energy consumption and reduced heat dissipation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

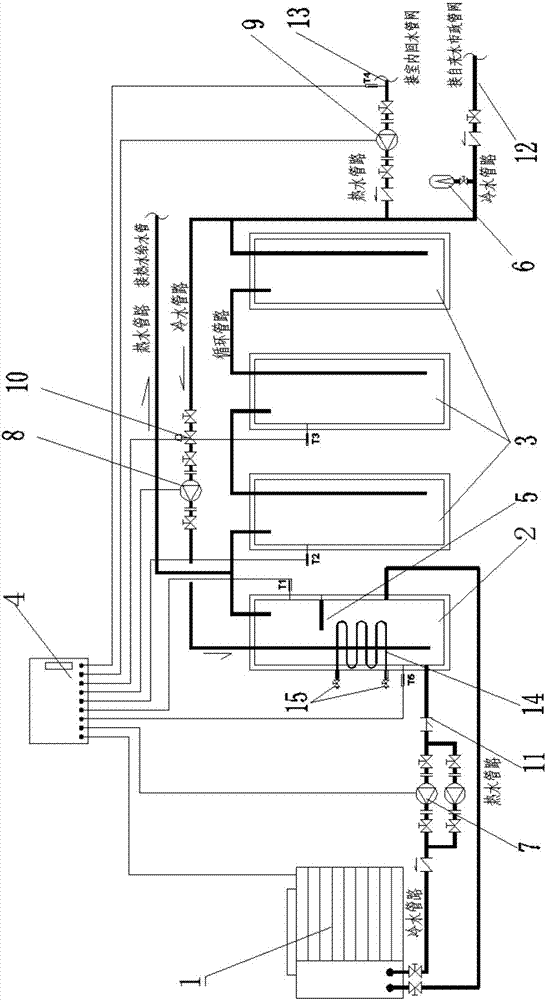

Embodiment 1

[0039] A modular pressurized heat pump system of this scheme, as figure 1As shown, host 1 is included, and host 1 can choose various heat pump hosts, such as an air source heat pump host, and also includes a heating water tank 2 and several hot water storage tanks 3 connected in series through circulation pipelines. In the scheme, three storage tanks are selected The hot water tank is connected to the water supply pipe 12 of the tap water municipal pipe network respectively connected to the heating water tank 2 and the first-stage hot water storage tank 3, and the water inlet of the water supply pipe 12 extends into the heating water tank 2 and the first-stage hot water storage tank 3 At the bottom, the three hot water storage tanks 3 are finally connected to the heating water tank 2 through the circulation pipeline; The third-stage hot water storage tank 3, so that the hot water in the upper part of the heating water tank 3 can enter the adjacent third-stage hot water storage...

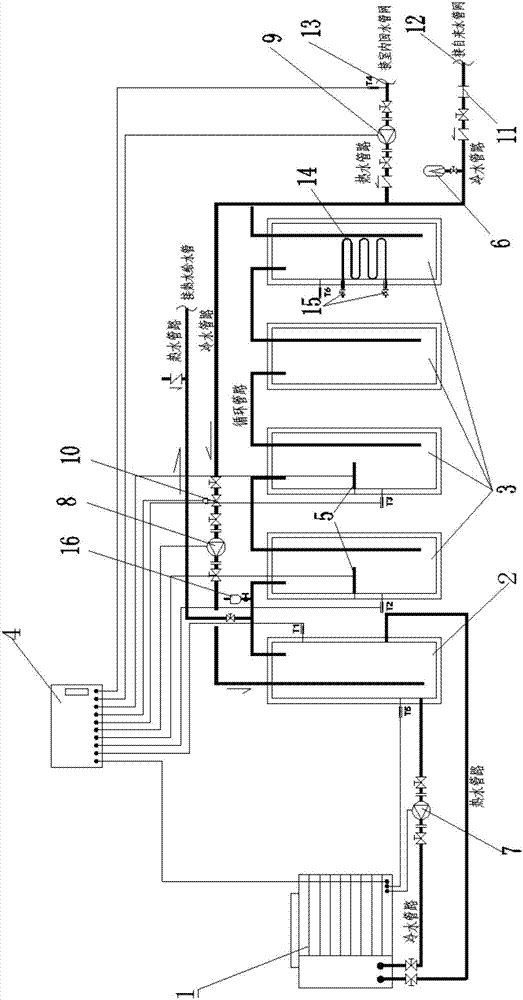

Embodiment 2

[0061] Such as figure 2 As shown, a modular pressurized heat pump system of this scheme includes a host 1, which can choose various heat pump hosts, such as an air source heat pump host, and also includes a heating water tank 2 and several series connected through circulation pipelines. The hot water storage tank 3, select 4 hot water storage tanks in the plan, and the replenishment pipes 12 connected to the tap water municipal pipe network are respectively connected to the heating water tank 2 and the first-stage hot water storage tank 3, and the water inlet of the replenishment pipe 12 extends into the heating In the water tank 2 and the bottom of the first-stage hot water storage tank 3, the three hot water storage tanks 3 are finally connected with the heating water tank 2 through the circulation pipeline; To the upper part of the adjacent hot water storage tank 3, this is the fourth-level hot water storage tank 3, so that the hot water in the upper part of the heating wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com