Pump unit bell-shaped inlet channel with movable flow plate

A technology of water inlet flow channel and pump device, which is applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, and can solve the problem of decreased uniformity of flow velocity distribution at the outlet section, deterioration of pump device performance, and partitions that cannot be realized The dynamic balance of water flow distribution and other issues can be improved to improve the flow velocity distribution, improve the hydraulic characteristics and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

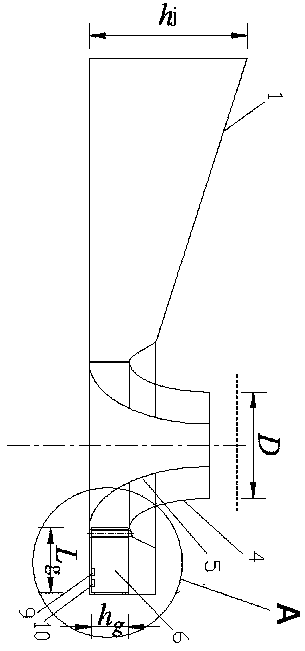

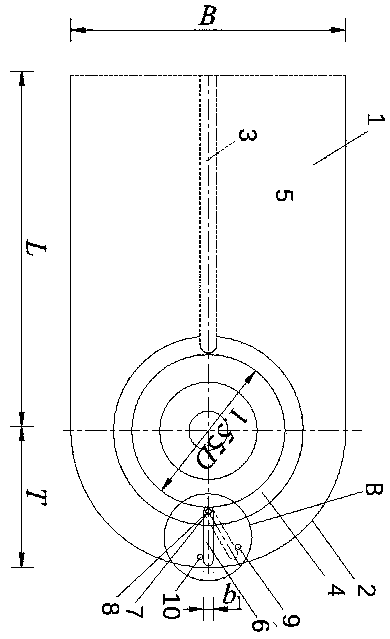

[0025] The present invention is suitable for bell-shaped water inlet channels and box-shaped water inlet channels, and the drawings are designed according to the design requirements.

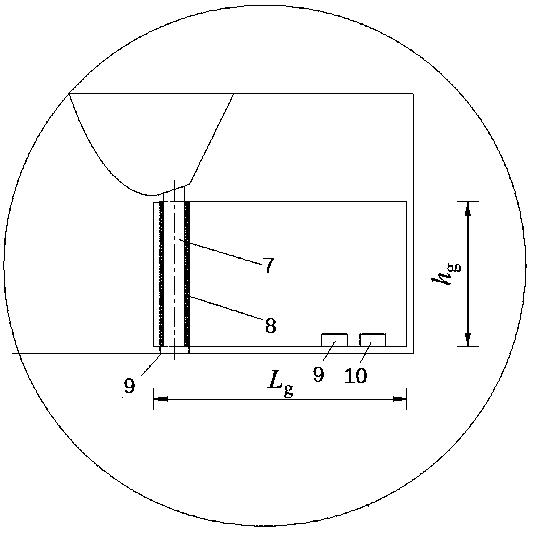

[0026] The bell-shaped water inlet flow channel of the pump device with a movable flow control plate, including a pier 3 placed in the water intake flow channel 1, a semicircular rear wall 2, a trumpet tube 4 and a water guide cone 5, a movable flow control plate, positioning Pin, the movable flow control plate is located at the rear wall 2 of the water inlet channel and there is a gap of 5 mm between the rear wall 2 and the rear wall 2.

[0027] The movable flow regulating plate is composed of a rotatable flow regulating plate 6, a fixed connecting shaft 8, and a casing 7. The section where the flow regulating plate 6 is located is perpendicular to the bottom surface of the water inlet channel 1, and the initial position of the centerline of the horizontal section of the flow regulating plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com