Efficient post-pressurization turbine expansion machine with adjustable nozzle and gas bearings

A turboexpander, gas bearing technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of reduced rigidity and bearing capacity of gas bearings, running cold energy, inconvenient disassembly, etc., to reduce comprehensive energy. Consumption, environmental protection, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

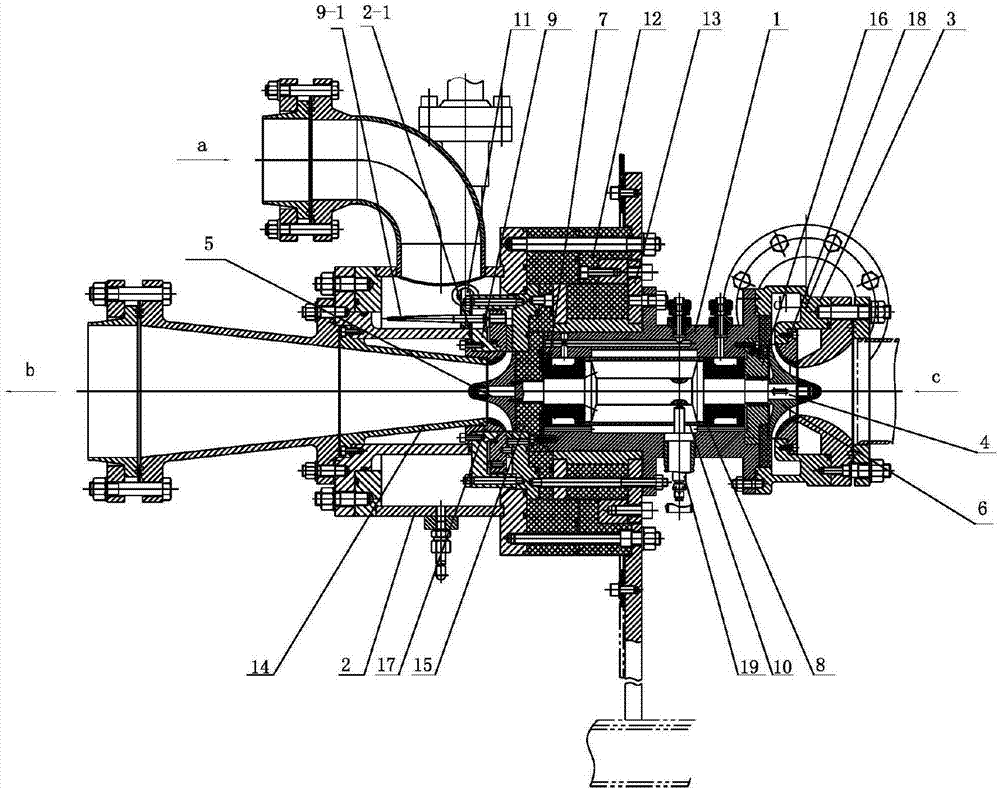

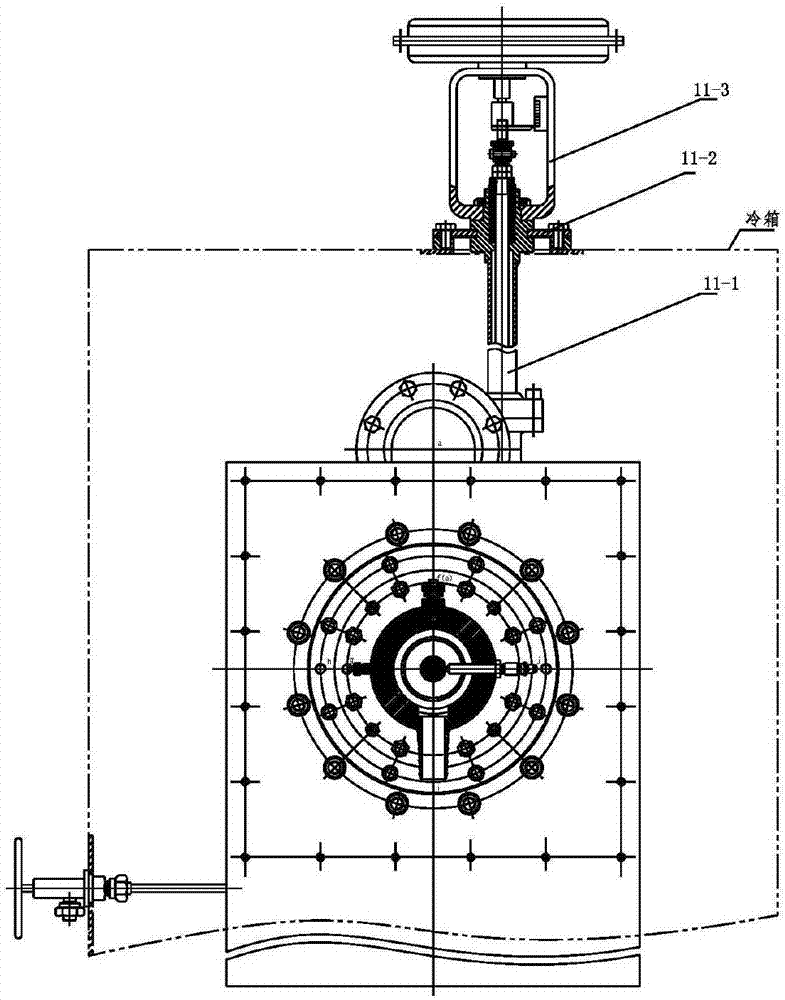

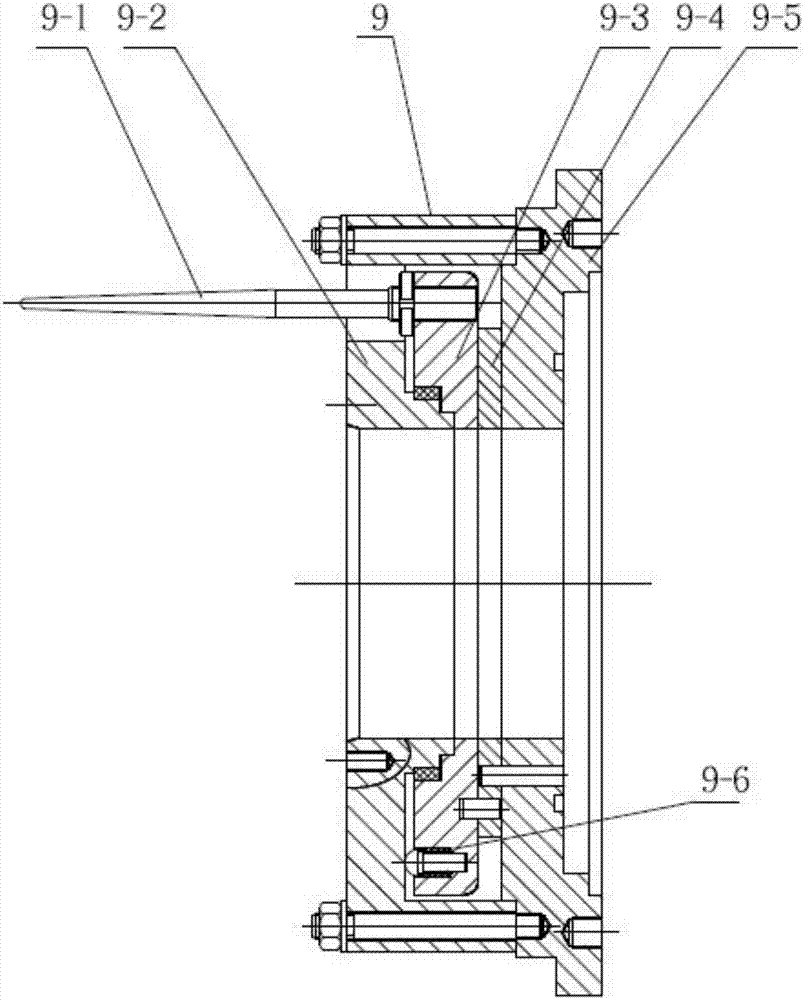

[0049] In order to better understand the technical content of the present invention, specific embodiments are given together with the accompanying drawings for description as follows.

[0050] The invention provides a high-efficiency post-pressurization adjustable nozzle gas bearing turbo expander, the biggest feature is that the air bearing is used instead of the oil bearing to achieve a large volume, saving more than 4 / 5 of the cost, and the energy of the expander can be recovered at the same time , its main purpose is to solve the technical problems caused by the combination of adjustable nozzles and gas bearings, improve the market competitiveness of products, and at the same time improve the overall level of expanders in my country.

[0051] It is worth mentioning that in order to improve the efficiency and operational reliability of the expander, the set of expanders can be applied to increase the expansion gas volume to 4000Nm through the optimized design of the combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com