An electronic steel cylinder that detects the pressure change inside the beer bottle during the filling process

An internal pressure, beer bottle technology, applied in measuring devices, liquid bottling, packaging, etc., can solve the problem of difficulty in accurately judging the rise of total oxygen in the bottle neck of beer bottles, indirect evaluation, and difficulty in accurately evaluating beer bottle vacuuming and backup pressure. and pressure relief effect to ensure authenticity and continuity, ensure sealing, and achieve the effect of communication and charging functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings. However, it should be understood that the accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

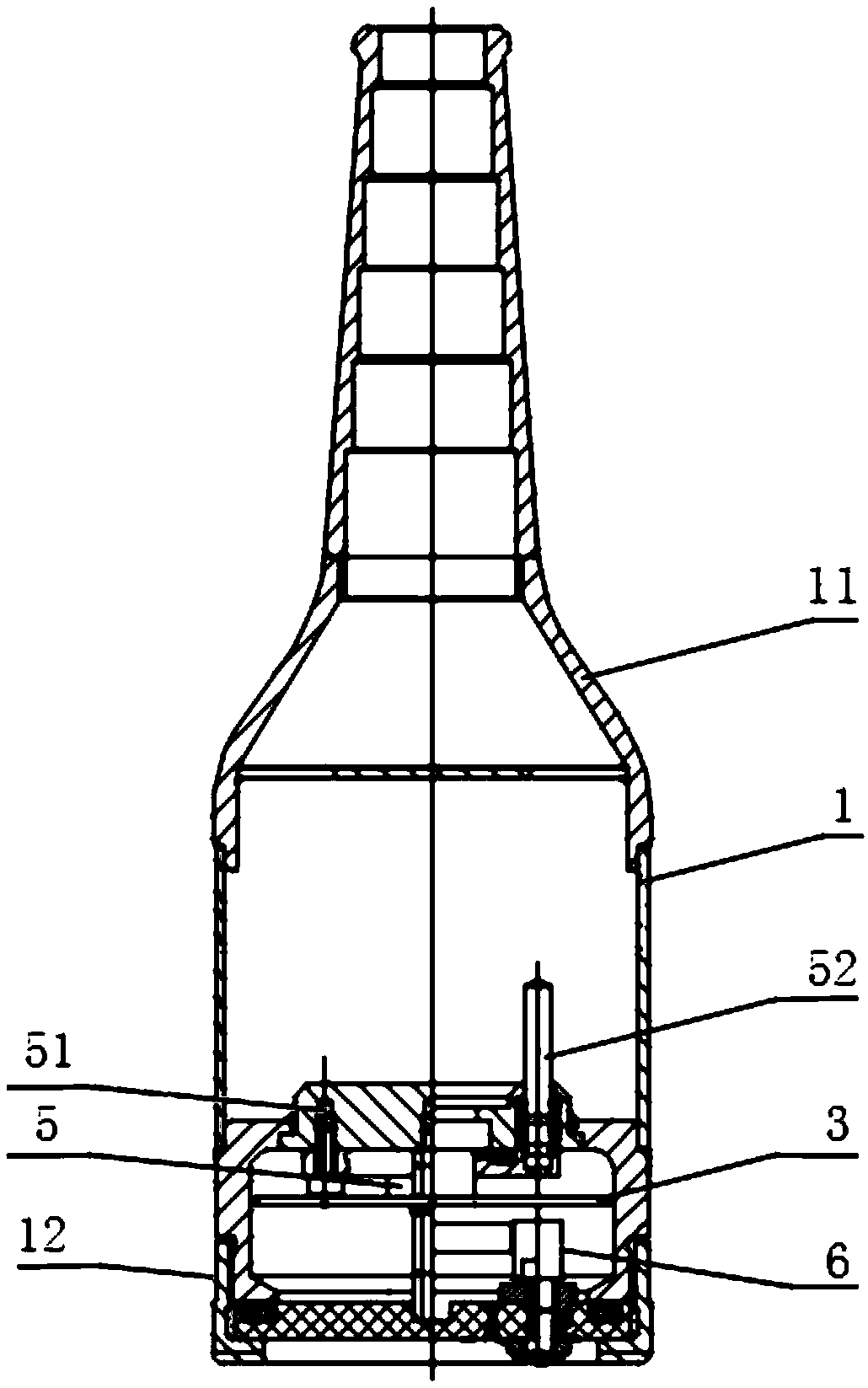

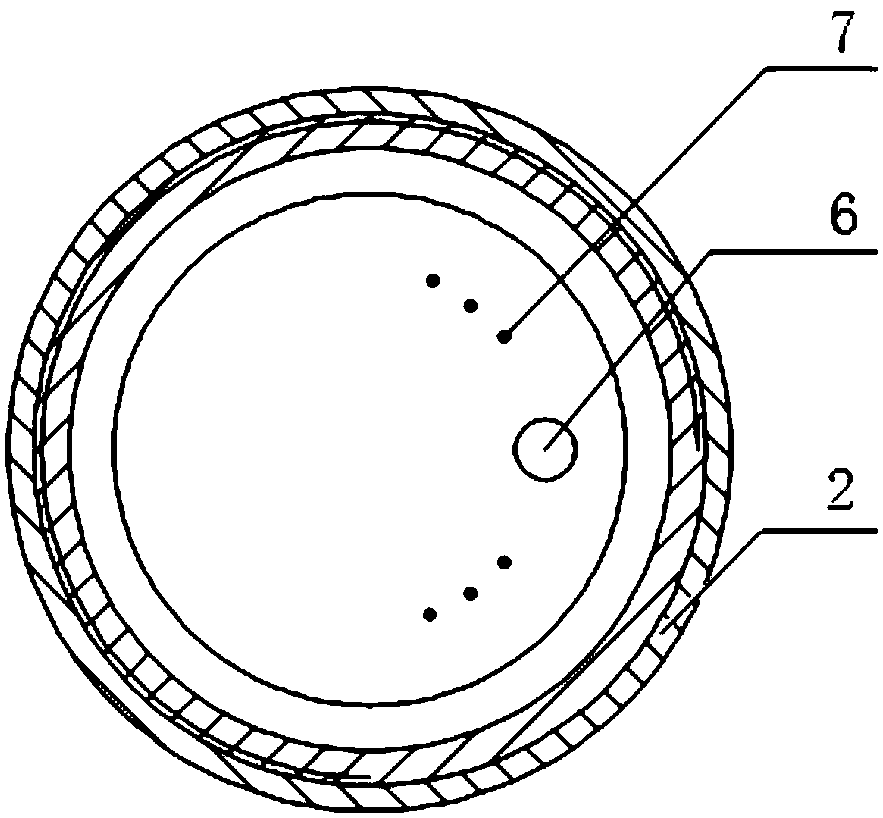

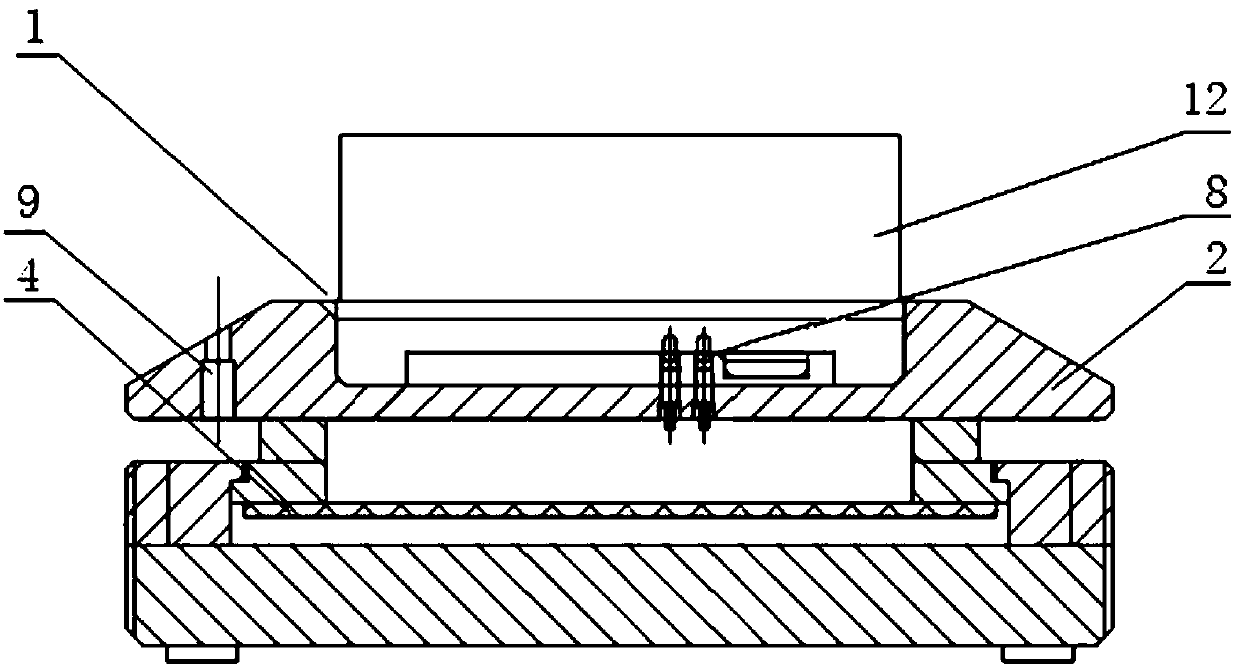

[0021] Such as Figure 1~3 As shown, the electronic steel cylinder provided by the present invention to detect the pressure change in the beer bottle during the filling process includes a bottle body 1, a communication charging base 2, a first circuit board 3, a second circuit board 4, a pressure temperature detection system 5, a single-chip microcomputer, Memory, switch 6, communication charging contact 7, pogo pin 8, USB interface, first LED light, second LED light 9 and host computer, wherein the bottle body 1 includes a bottle body 11 and a bottle bottom 12.

[0022] The bottle body 11 adopts the structure with the same size and shape as the ordinary beer bottle an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com