Roll paper sorting device

A sorting device and roll paper technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems of roll paper damage, unsuitable for sorting roll paper, etc., and achieve reliable connection, good anti-skid effect, The effect of improving the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

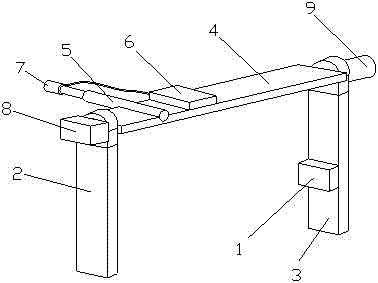

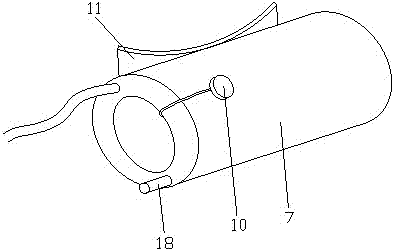

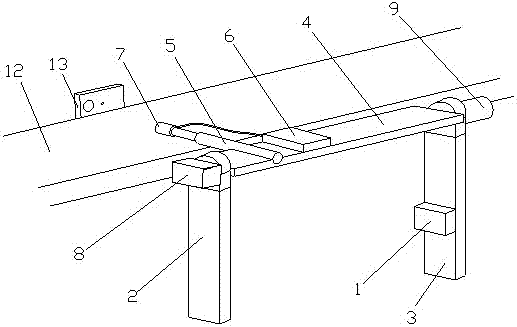

[0024] Such as Figure 1-2 As shown, a roll paper sorting device includes a movable clamp and PLC1. The movable clamp includes a first connecting rod 2, a second connecting rod 3 and a carrier board 4, and an electric telescopic rod is provided on the carrier board 4 5 and an inflator 6, the electric telescopic rod 5 is covered with a cylindrical airbag 7, the inflator 6 and the cylindrical airbag 7 are connected by a trachea (not shown), and both ends of the carrier plate 4 are provided with rotating Pins (not shown), the first connecting rod 2 and the second connecting rod 3 are both provided with bearing seats (not shown) that are matched with the rotating pins, and the rotating pins at both ends of the carrier board 4 are respectively connected with The encoder 8 and the steering gear 9, the first connecting rod 2 and the second connecting rod 3 are bolted to the encoder 8 and the steering gear 9, respectively, the electric telescopic rod 5, the encoder 8, the air pump 6 and...

Embodiment 2

[0027] Such as Figure 2-5 As shown, a roll paper sorting device includes a movable clamp and PLC1. The movable clamp includes a first connecting rod 2, a second connecting rod 3 and a carrier board 4, and an electric telescopic rod is provided on the carrier board 4 5 and an inflator 6, the electric telescopic rod 5 is covered with a cylindrical airbag 7, the inflator 6 and the cylindrical airbag 7 are connected by a trachea (not shown), and both ends of the carrier plate 4 are provided with rotating Pin (not shown), the rotating pin and the carrier board are integrally arranged, the first connecting rod 2 and the second connecting rod 3 are both provided with a bearing seat matched with the rotating pin, the first connecting rod 2 and the second connecting rod The two connecting rods 3 are respectively welded to their respective bearing seats, the rotating pins at both ends of the carrier plate 4 are respectively connected with an encoder 8 and a steering gear 9, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com