Vertical-horizontal combined film evaporator

A thin-film evaporator and combined technology, which is applied in the field of vertical-horizontal combined thin-film evaporators, can solve problems such as fast flow rate, failure to meet drying requirements, and insufficient treatment concentration, etc., to achieve continuous process, minimized losses, and high energy efficiency The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

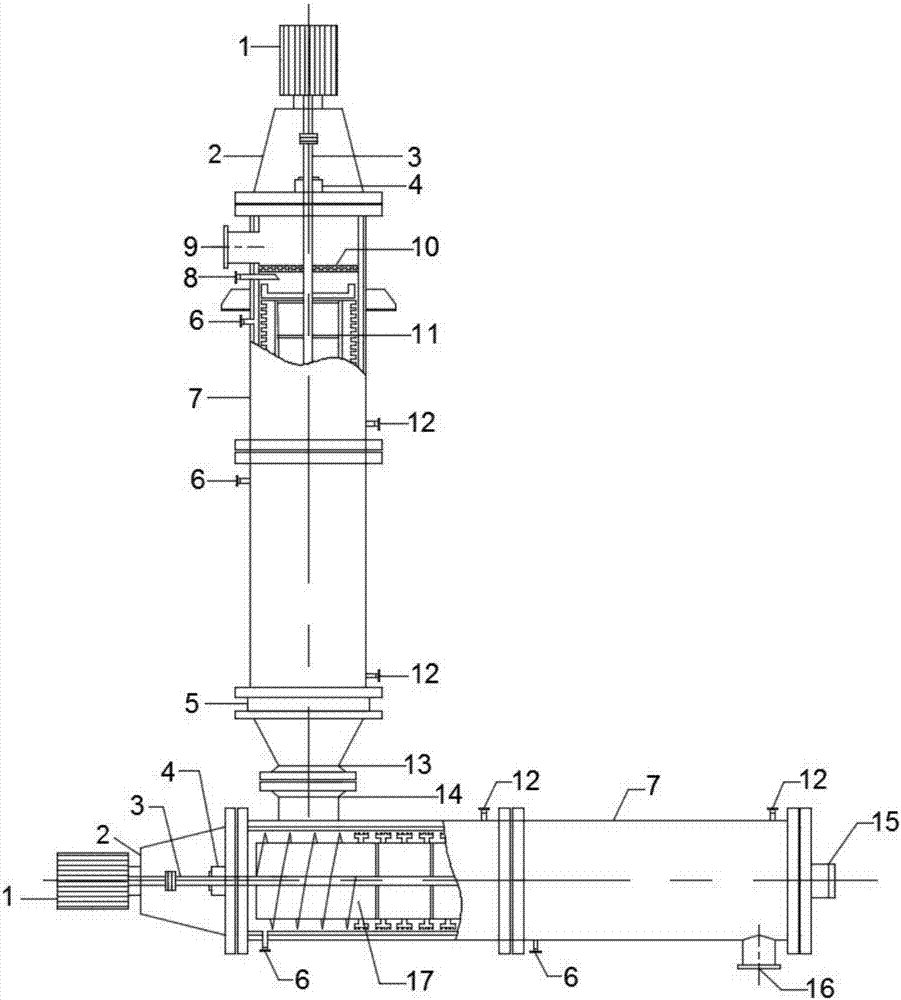

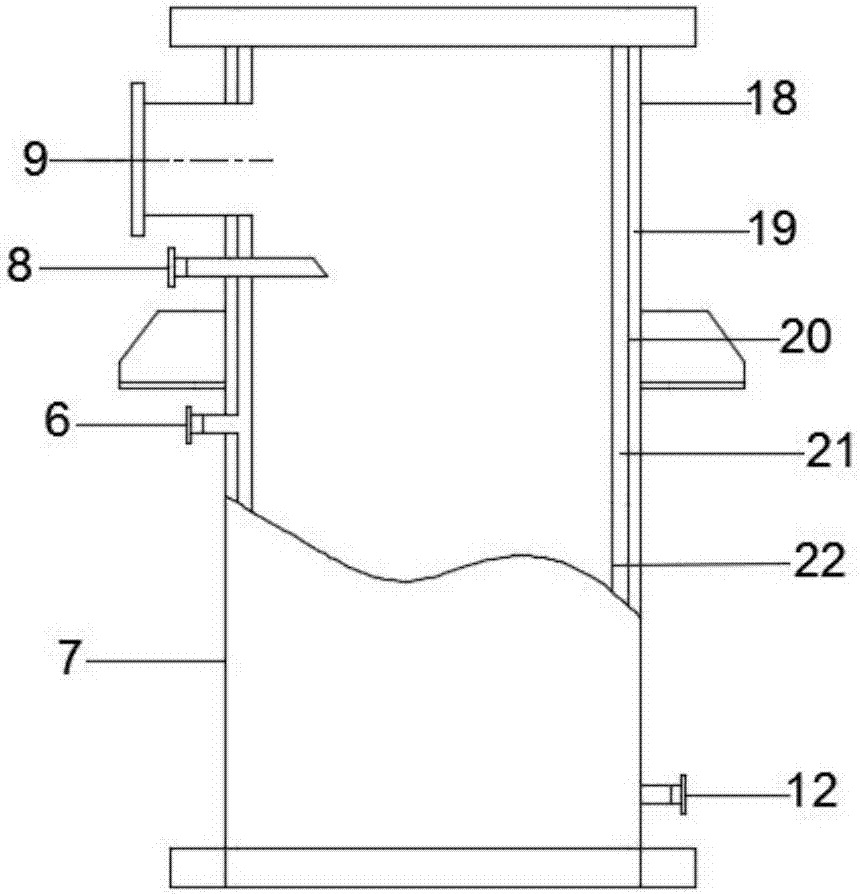

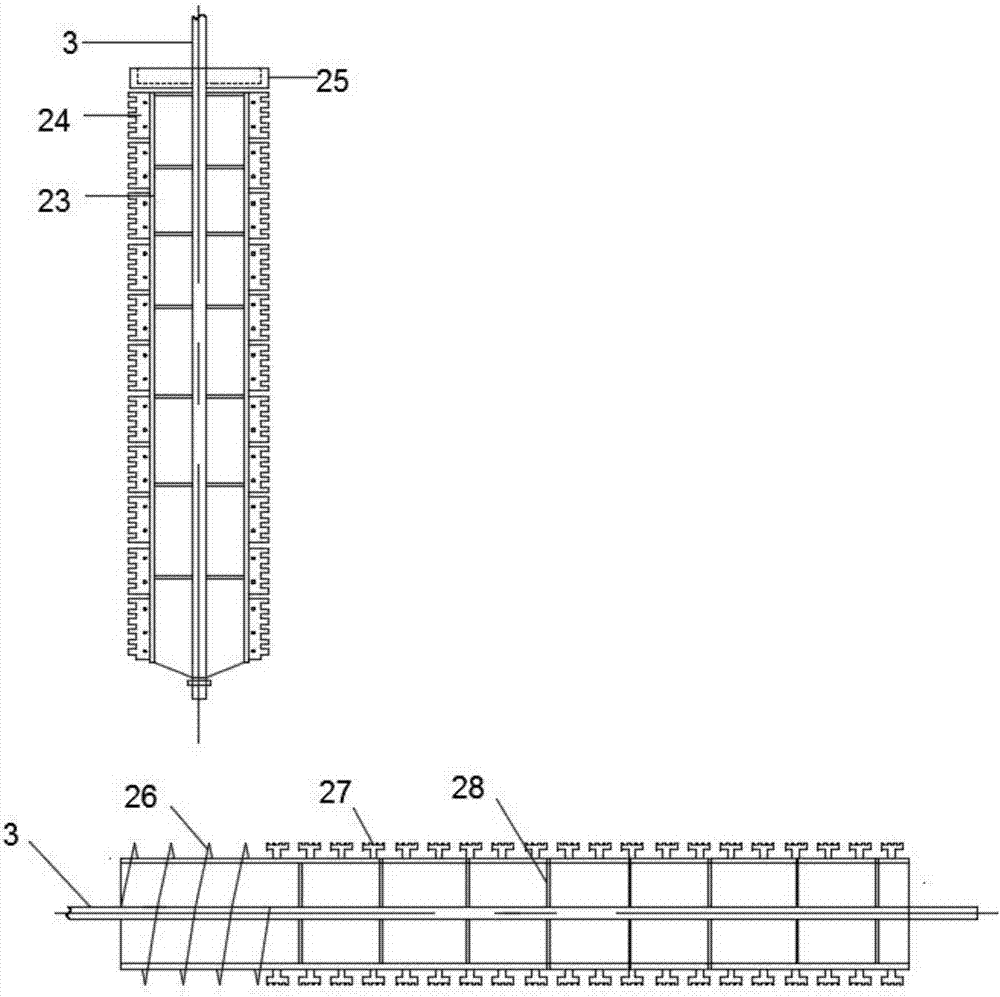

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Such as figure 1 As shown, the present invention provides a vertical and horizontal combined thin film evaporator, including a vertical thin film evaporator, a horizontal thin film evaporator, a discharge port 13 of the vertical thin film evaporator and a feed port 14 of the horizontal thin film evaporator Connected by flange bolts; vertical thin film evaporator includes motor 1, reducer 2, main shaft 3, cylinder 7, rotor 11, foam capture and separation device 10, bottom bearing 5, horizontal thin film evaporator includes motor 1, reducer 2. Main shaft 3, barrel 7, rotor 17, end bearing 15; motor 1 is connected to reducer 2, reducer 2 is directly connected to main shaft 3 through a key, and mechanical seal 4 is used between main shaft 3 and barrel 7; The rotor 17 is rigidly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com