Automatic turnover device of circuit board welding machine for charging pile production

A technology of automatic flipping and circuit board, applied in the direction of printed circuit, printed circuit manufacturing, assembling printed circuit with electrical components, etc., to achieve the effect of not easy to shake, reduce welding errors, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

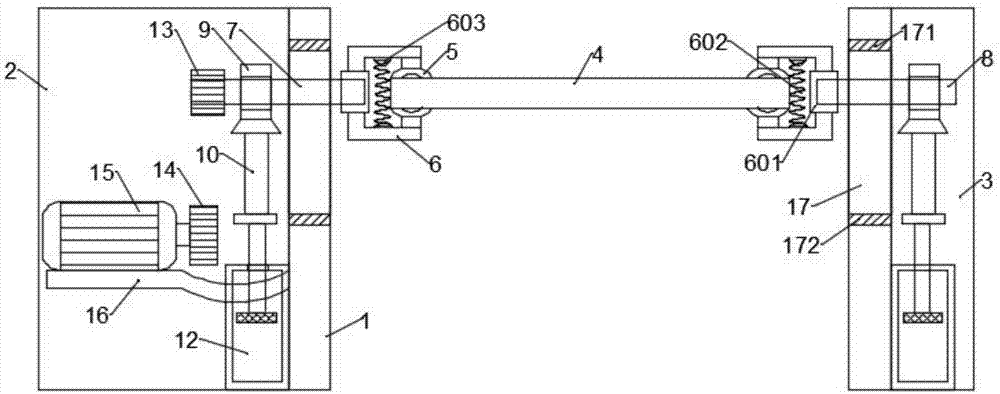

[0024] Such as figure 1 with figure 2 As shown, the present invention provides an automatic turning device of a circuit board welding machine for charging pile production, including a turning frame 1, and the left and right ends of the turning frame 1 are symmetrically installed with an active turning body 2 and a driven turning body 3, and a circuit board 4 is arranged in the middle of the flip frame 1, and the two ends of the circuit board 4 are connected to the clamping frame 6 through the adsorption suction cups 5, wherein the number of the adsorption suction cups 5 is sixteen in total, and The suction cups 5 are symmetrically installed on the upper and lower sides of the circuit board 4, so that four pairs of clamping frames 6 are symmetrically installed at both ends of the circuit board 4, so that the circuit board 4 can be effectively clamped, making it difficult for the circuit board 4 to Shake occurs, and the clamping frame 6 is fixedly installed on the driving shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com