Steel-concrete combined continuous beam bridge for releasing pulling stress of carriageway slab

A bridge slab and tensile stress technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems of bridge slab structure complexity and difficulty in reaching the ideal level, and achieve simplified structure and construction technology, avoiding tension, and extending The effect of the use cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

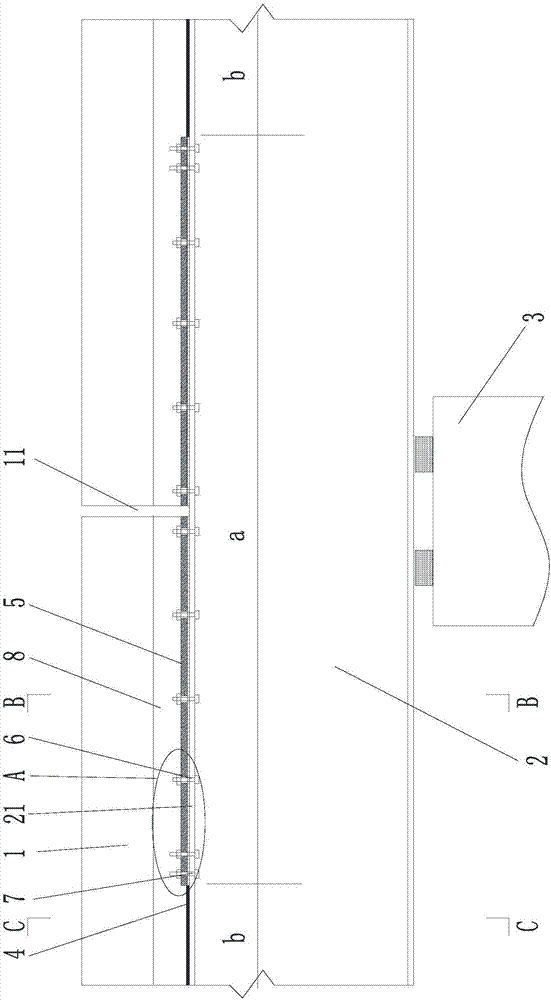

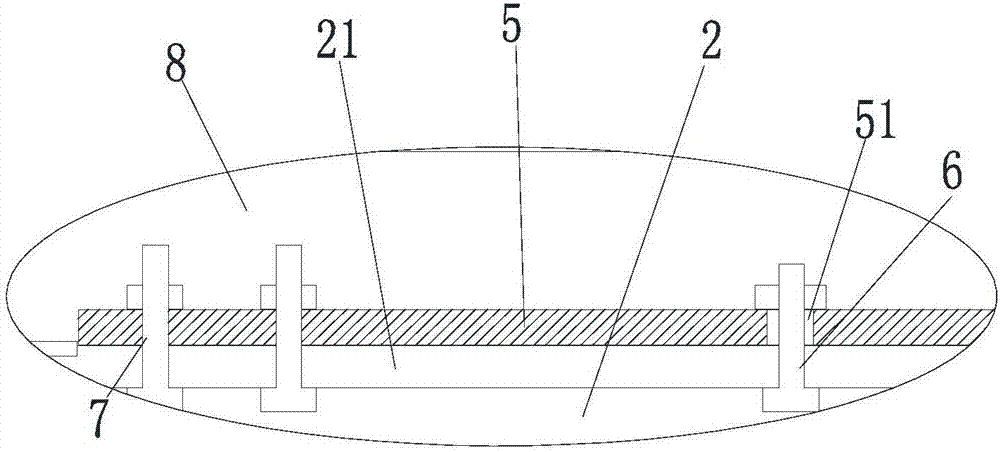

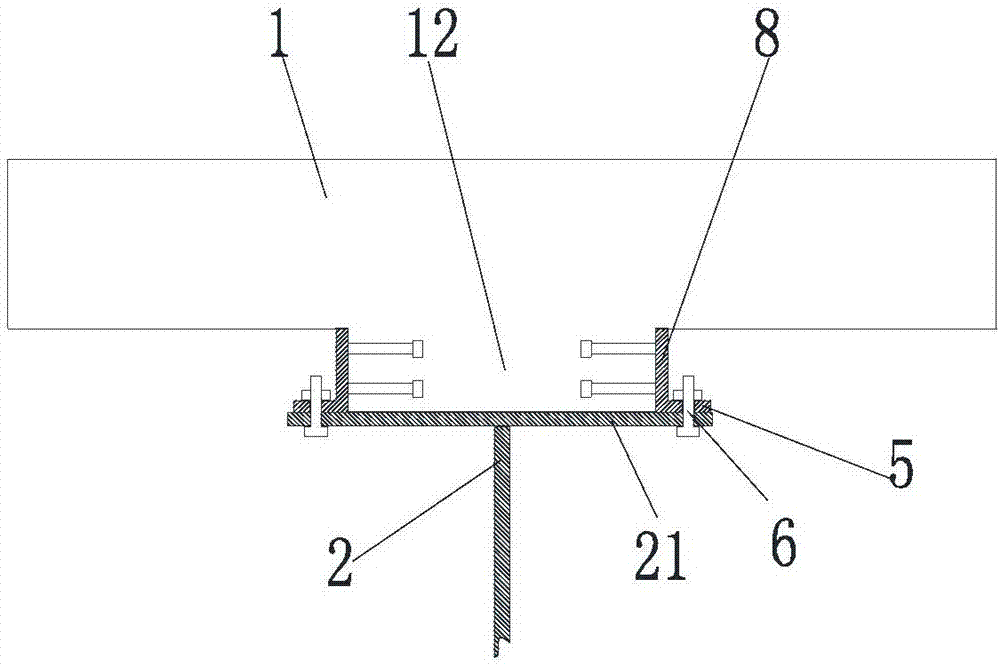

[0019] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Enlarged view at A, image 3 for figure 1 B-B direction sectional schematic diagram, Figure 4 for figure 1 C-C section schematic diagram, as shown in the figure: the steel-concrete composite continuous girder bridge for releasing the tensile stress of the bridge slab in this embodiment includes a steel girder 2 and a concrete bridge slab 1 fixed on the steel beam 2, the concrete The bridge slab 1 is provided with a transverse through-through fracture 11 above the middle pier 3 corresponding to the continuous girder bridge, and the concrete bridge slab 1 and the steel girder 2 are arranged on both sides of the transverse through-through fracture 11 (along the longitudinal two sides of the bridge). Side) The local section has relatively longitudinal expansion and contraction deformation, that is, the section between the concrete bridge slab 1 and the steel beam 2 can slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com