Ultrasonic stripping-membrane distillation technology combined landfill leachate treatment system and method

A technology of landfill leachate and ultrasonic stripping, applied in multi-stage water treatment, energy waste water treatment, water/sewage treatment and other directions, can solve the problems that have not been seen before, and achieve the effect of simple equipment, saving operating costs and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

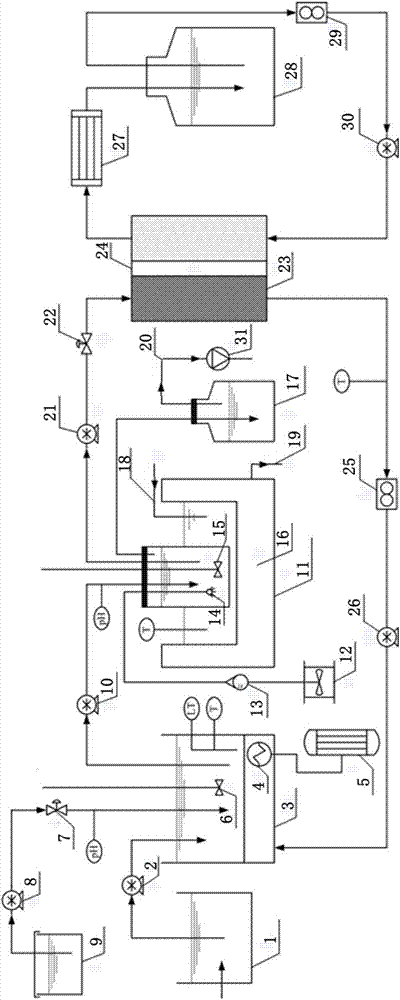

[0033] Such as figure 1 As shown, a landfill leachate treatment system combined with ultrasonic stripping-membrane distillation technology includes a water inlet tank 1, an ultrasonic stripping pool 11 and a membrane distillation system, and the membrane distillation system includes a sequentially connected first sewage pump 2, Membrane distillation heating tank 3, membrane distillation reactor 23, condenser 27 and clear water tank 28; the water inlet tank 1 is connected to the first sewage pump 2 pipelines, and the ultrasonic stripping tank 11 is located between the membrane distillation heating tank 3 and the membrane distillation tank. Between the reactors 23; the membrane distillation heating pool 3, the ultrasonic stripping pool 11 and the membrane distillation reactor 23 are connected sequentially through pipelines, and form a circulation loop, wherein the pipeline connecting the membrane distillation heating pool 3 and the ultrasonic stripping pool 11 is provided with T...

Embodiment 2

[0040] Based on the landfill leachate treatment system combined with ultrasonic stripping-membrane distillation technology of embodiment 1, its treatment principle and method are as follows:

[0041] (1) Garbage leachate adjustment: turn on the first sewage pump 2 and pass the garbage leachate in the water inlet pool 1 into the membrane distillation heating pool for heating treatment. The heat in the heating pool is provided by solar energy, and the temperature of the garbage leachate in the pool reaches the set value After setting the temperature range of 65-75°C, adjust the pH value of the landfill leachate to the set range of 11-13;

[0042] The purpose of landfill leachate adjustment is to promote the conversion of ammonia nitrogen in landfill leachate into gaseous ammonia on the one hand, and strengthen the removal effect of ammonia nitrogen by the subsequent ultrasonic stripping method. On the other hand, the high temperature condition of the membrane distillation heating...

Embodiment 3

[0047] Using the above device and method to treat the landfill leachate produced by a certain landfill in Jiangsu, the steps are as follows: (1) put the leachate produced by the landfill into the membrane distillation heating pool 3, heat treatment, and treat the leachate After the temperature rises to 70°C, the pH value of the leachate is adjusted to about 11 through the pH sensor, computer program and pH adjustment tank 9;

[0048] (2) After the water temperature and pH are adjusted, the landfill leachate enters the ultrasonic stripping tank 11 through the second sewage pump 10 for pretreatment, the water temperature is controlled at 55-65°C, the pH is between 11-13, and the ultrasonic stripping time It is 120min, and the sound energy density is 0.05W / mL. The gas (including ammonia and gaseous volatile organic compounds) blown out by ultrasound is absorbed or discharged out of the pool through the absorption bottle 17; and the leachate after pretreatment is discharged into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com