Titanium pipe carrying vehicle

A technology for pallet trucks and titanium tubes, which is used in transportation and packaging, conveyors, mechanical conveyors, etc., and can solve problems such as uneven force, affecting handling speed, and pallet trucks stuck on the track.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

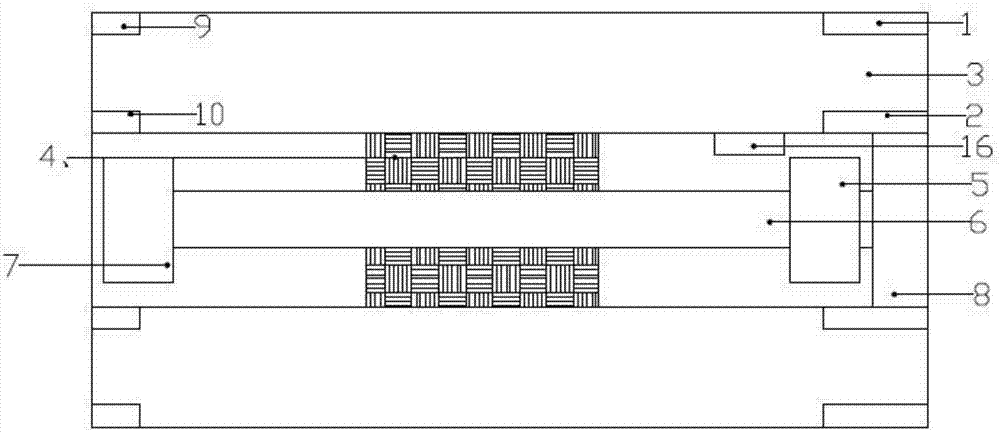

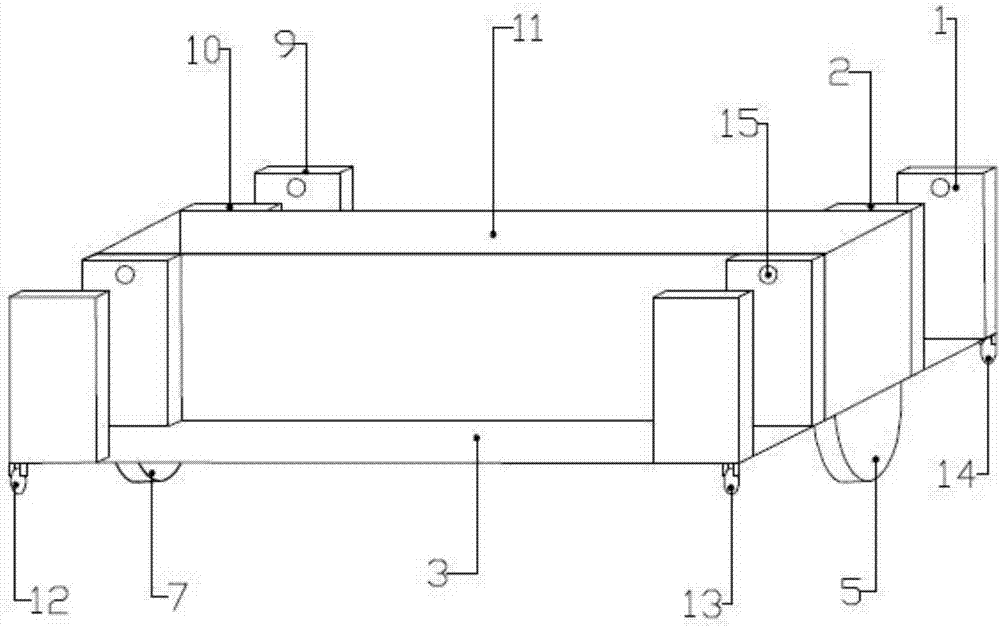

[0015] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0016] A titanium tube transport vehicle, comprising a bearing frame 11, two limit mechanisms, a right roller 5, a connecting shaft 6, a left roller 7, a motor 8 and a controller, and an opening is opened on the top wall of the bearing frame 11 , the connecting shaft 6 is located in the carrying frame 11, the motor 8 is fixedly arranged in the carrying frame 11, the left end of the connecting shaft 6 is rotatably connected to the carrying frame 11, and the connecting shaft The right end of 6 is fixedly connected to the output shaft of the motor 8, the left roller 7 is sleeved and fixedly connected to the left end of the connecting shaft 6, the right roller 5 is sleeved and fixedly connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com