High-precision solving device and method for calibrated and fitted circle centers

A circle-fitting, high-precision technology, applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as machine tool errors, waste of processing production time, and failure to obtain coordinate values, and achieve evaluation accuracy Improve, avoid data loss, and avoid the effect of insufficient precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0022]

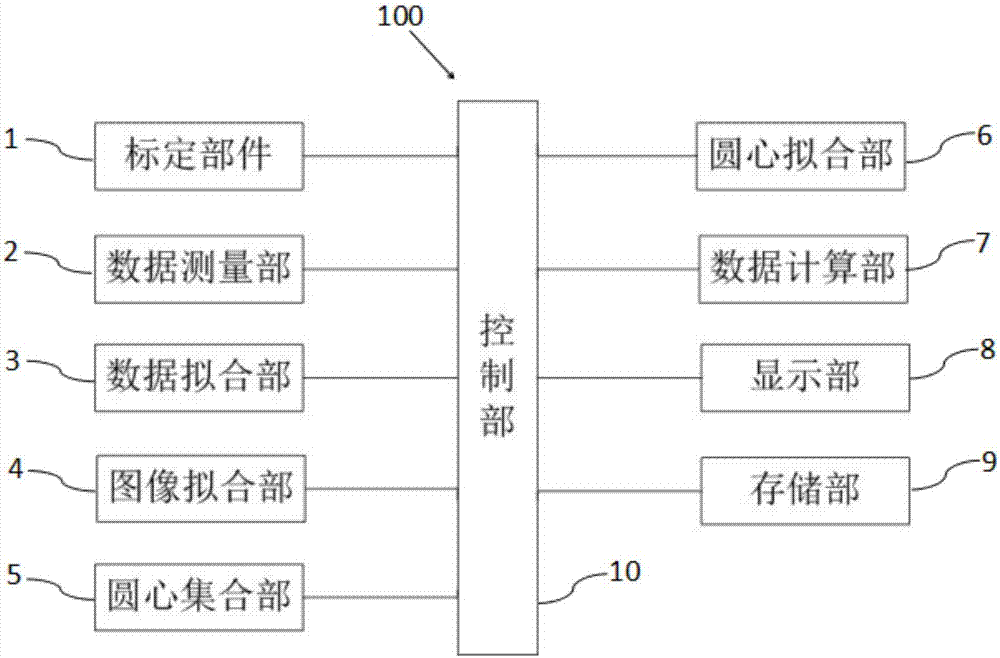

[0023] figure 1 It is a block diagram of the high-precision calibration and fitting circle center solution device in the embodiment of the present invention.

[0024] Such as figure 1 As shown, the high-precision calibration and fitting circle center solution device 100 is set in the machine tool, including: a calibration component 1, a data measurement unit 2, a data fitting unit 3, an image fitting unit 4, a circle center collection unit 5, and a circle center fitting unit 6 , a data calculation unit 7 , a display unit 8 , a storage unit 9 and a control unit 10 , wherein the control unit 10 is used to control each component of the accuracy calibration fitting circle center solving device 100 to work.

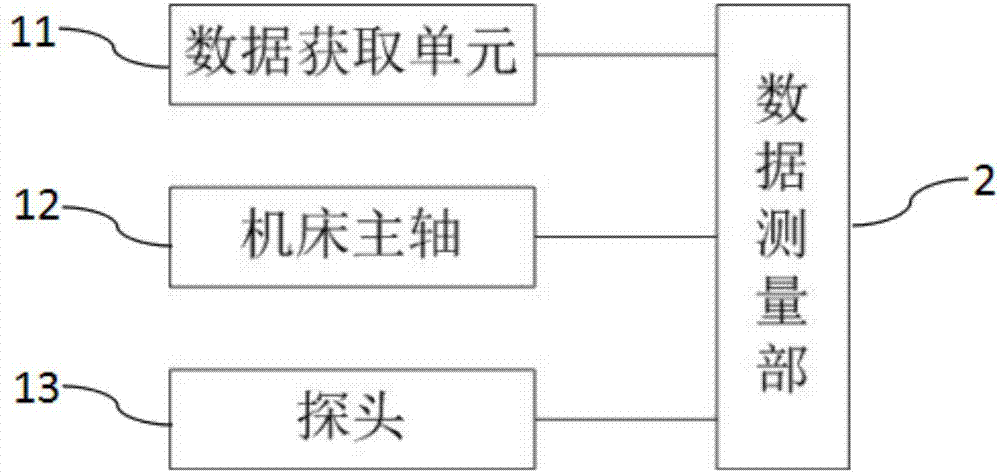

[0025] figure 2 It is a schemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com