Valve base tightening device for ball valve assembly

A tensioning device and valve seat technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty, and achieve the effects of low cost, simple structure, and improved installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

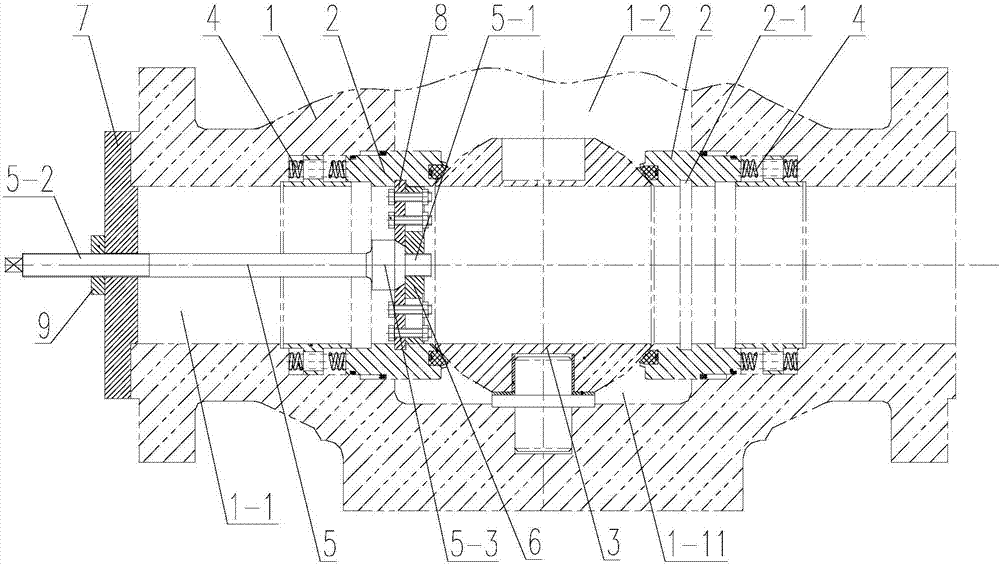

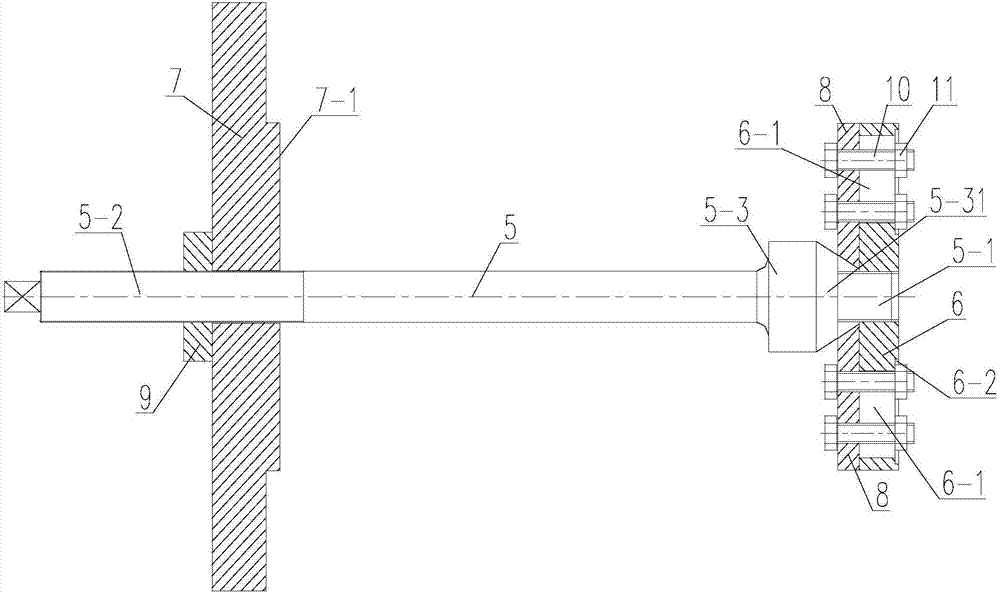

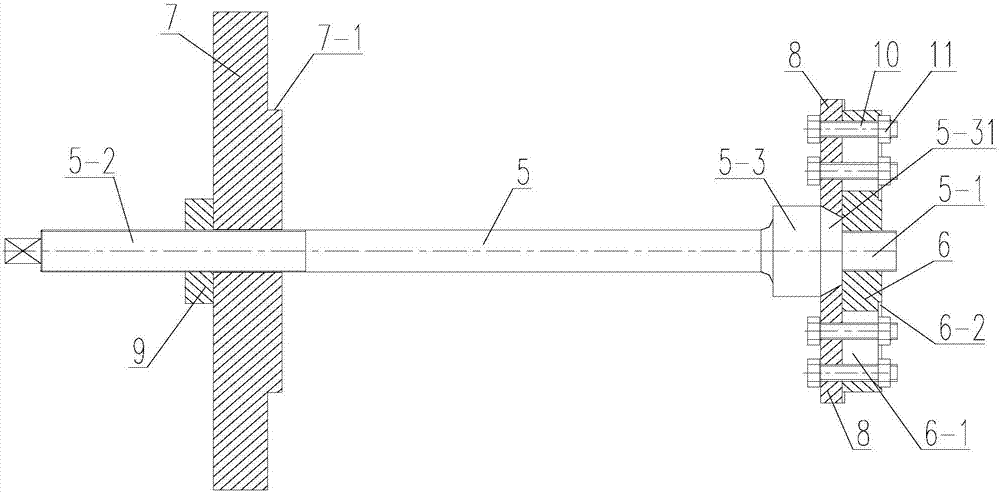

[0029] like Figure 1-6 As shown, a valve seat tensioning device for ball valve assembly, the ball valve includes a valve body 1 and a valve seat 2, the valve body 1 has a flow channel 1-1 running through it, and the valve body 1 has a ball communicating with the flow channel 1-1. The core insertion hole 1-2, the position of the flow channel 1-1 facing the ball core insertion hole 1-2 has a valve cavity 1-11 for installing the ball core 3, and the valve cavity 1-11 is along the flow channel 1-1. Both ends of the direction are provided with valve seats 2. There is an elastic element 4 between the outer side of the valve seat 2 and the valve body 1. The elastic element 4 is a spring. The tensioning device includes a pull rod 5, a base 6 and a The backing plate 7 at the end of the body 1, the backing plate 7 is sleeved on the pull rod 5;

[0030] The front end of the pull rod 5 has a push section 5-3, the front end of the push section 5-3 is extended with a first threaded sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com