O-shaped shaft clasping type large-current seam welding electrode

A high-current, shaft-type technology, applied in the direction of electrode characteristics, roller electrode welding, etc., can solve the problems of short service life of the electrode, damage of the roller electrode, and influence on the stability of the transmission current, so as to prevent the oxidation of the silver tile surface and prolong the service life. life, and the effect of reducing the receiving area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

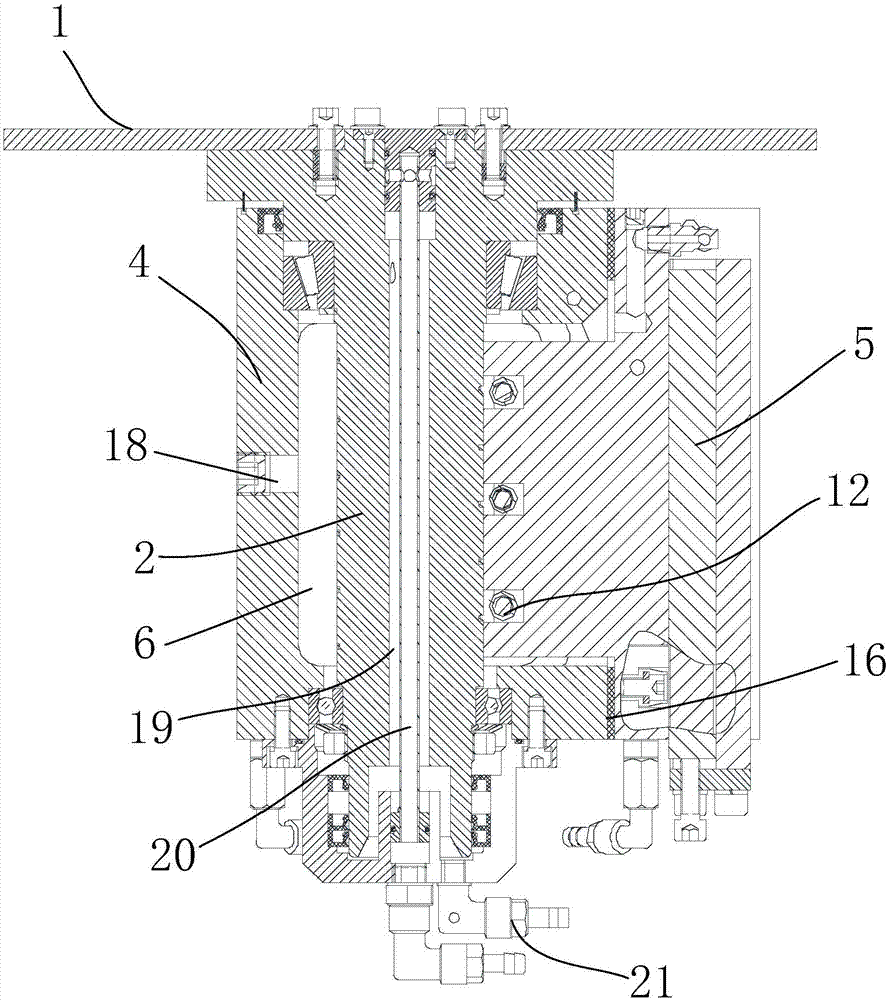

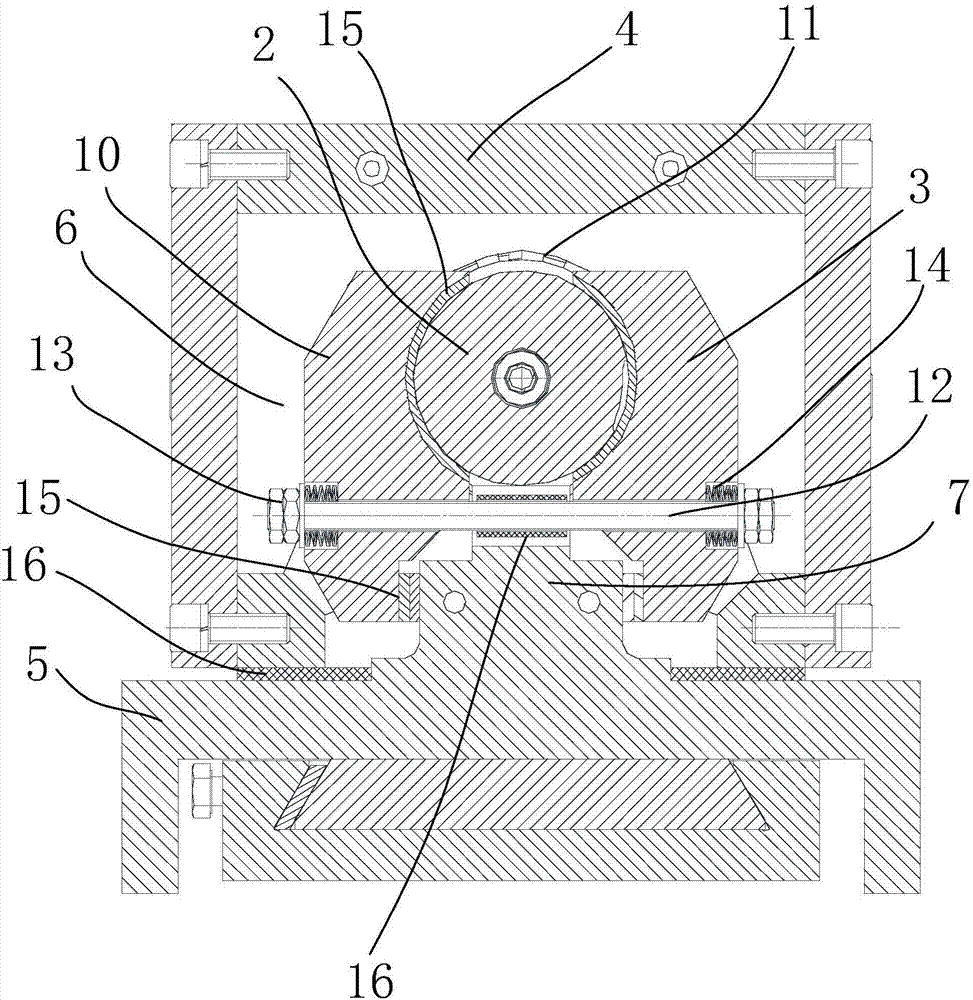

[0026] The present invention will be further described below with reference to the accompanying drawings and examples, and the implementation of the present invention includes but not limited to the following examples.

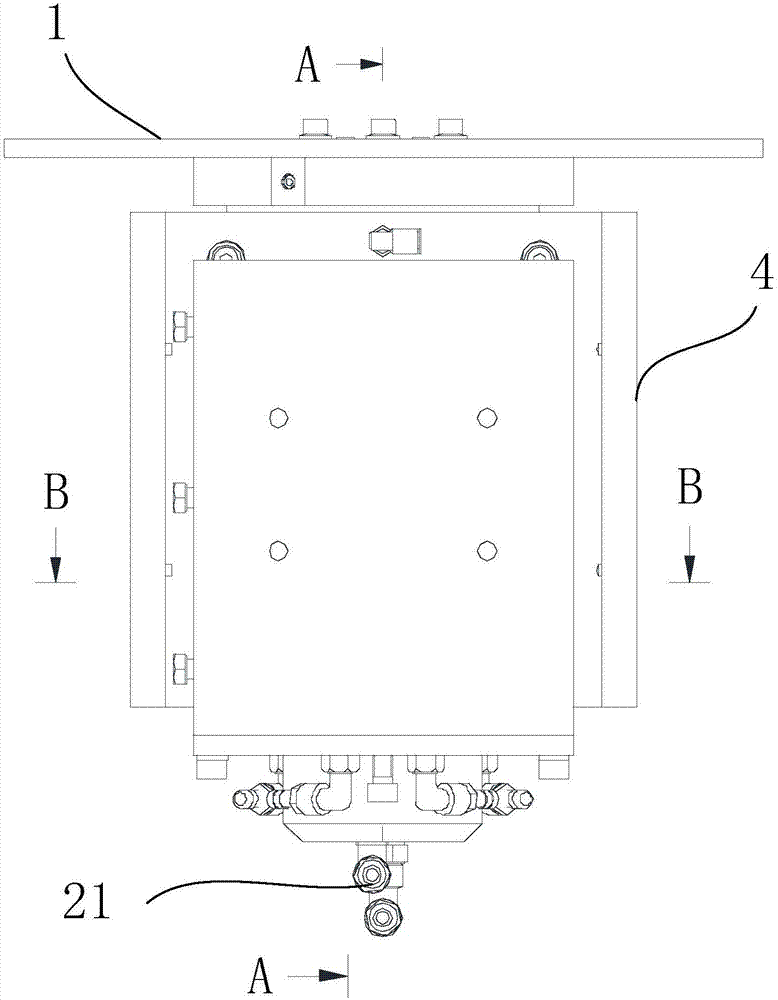

[0027] Such as Figure 1~5 As shown, an O-shaped shaft-holding high-current seam welding electrode includes an electrode roller 1, a rotating spindle 2, a conductive block 3, a shell 4, and a conductive base 5; wherein, the conductive block 3 is an O-shaped embracing, conductive The block 3 includes two conductive base blocks 10 arranged symmetrically along the main axis of rotation 2, used to fasten the two conductive base blocks 10 so that the conductive block 3 is close to the fastening bolt assembly of the main shaft of rotation 2, and arranged on the upper part of the conductive base block 10 The connecting wire 11 used to connect two conductive base blocks 10, the conductive base 10 is provided with an arc-shaped groove that fits with the rotating main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com