Air filtering absorber

A technology for filtering absorbers and air filtering devices, which is applied in the directions of dispersed particle filtering, chemical instruments and methods, transportation and packaging, etc., to achieve the effects of small resistance, increased service life, and high purification and capture efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] Example. An air filter absorber

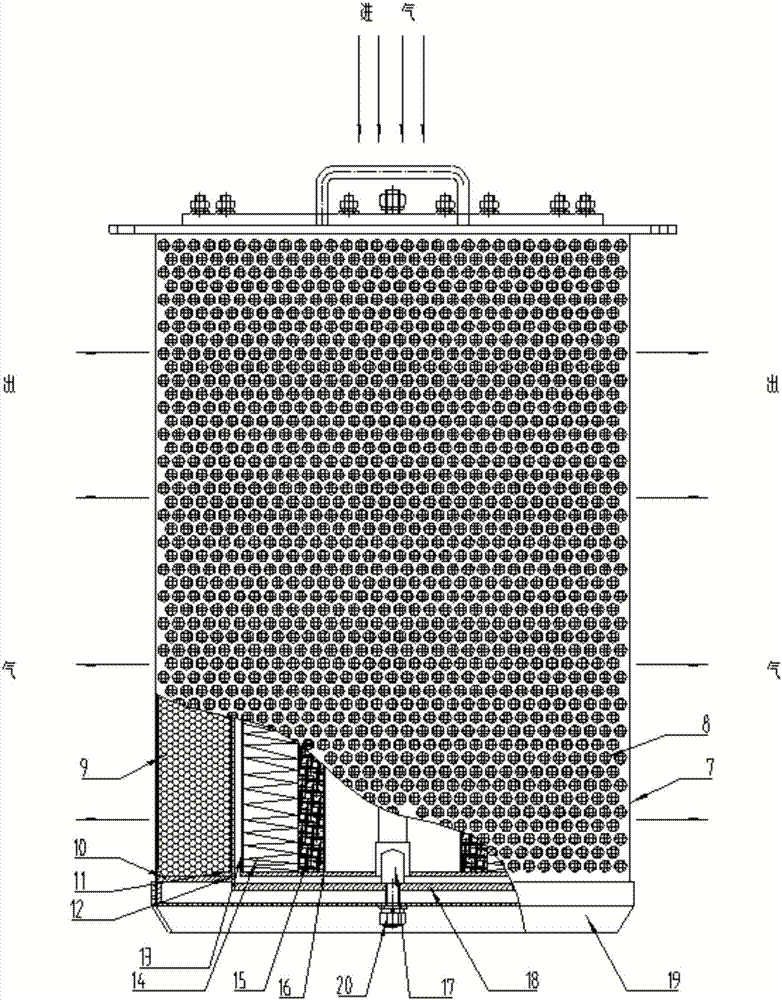

[0025] figure 1 , figure 2 The structure of the air filter absorber of this embodiment is shown in front view and top view respectively.

[0026] The filter absorber has a cylindrical structure, and from outside to inside there are filter absorber shell 4, filter absorber outer orifice plate 7, outer wire mesh 8, inner wire mesh 11, filter absorber inner hole plate 12, paper filter outer Orifice plate 13, orifice plate 16 in paper filter. The inner and outer orifice plates of the filter absorber are made of 1.5mm thick stainless steel plate rolled round, and the inner and outer wire meshes are spot-welded. There is an activated carbon adsorption layer 9 between the inner and outer wire meshes, and the filler is impregnated activated carbon (the activated carbon particles are columnar, with a particle size of 0.7-1.0mm , the strength is greater than 90%, and the packing density is greater than 0.4g / cm 3 , the benzene adsorption rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com