Visualized remote control feeder

A technology of remote control and control system, applied in the field of feeding machines, can solve the problems of too many equipment and long time required to go out, and achieve the effect of saving space and reducing supporting equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

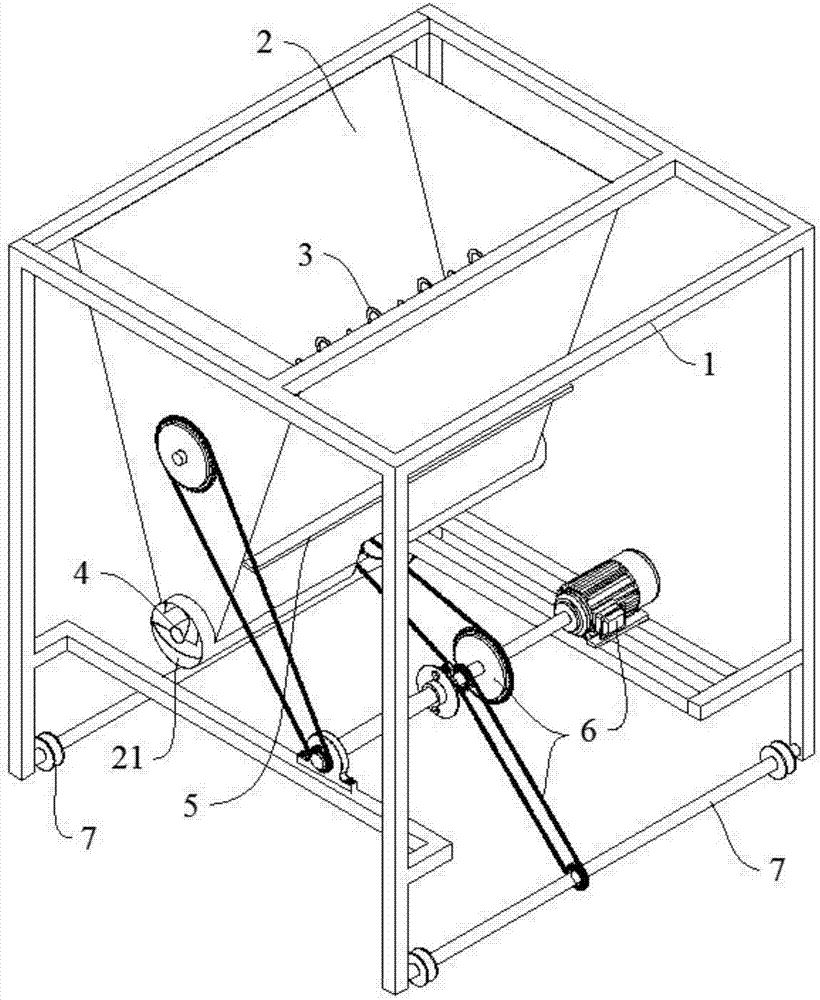

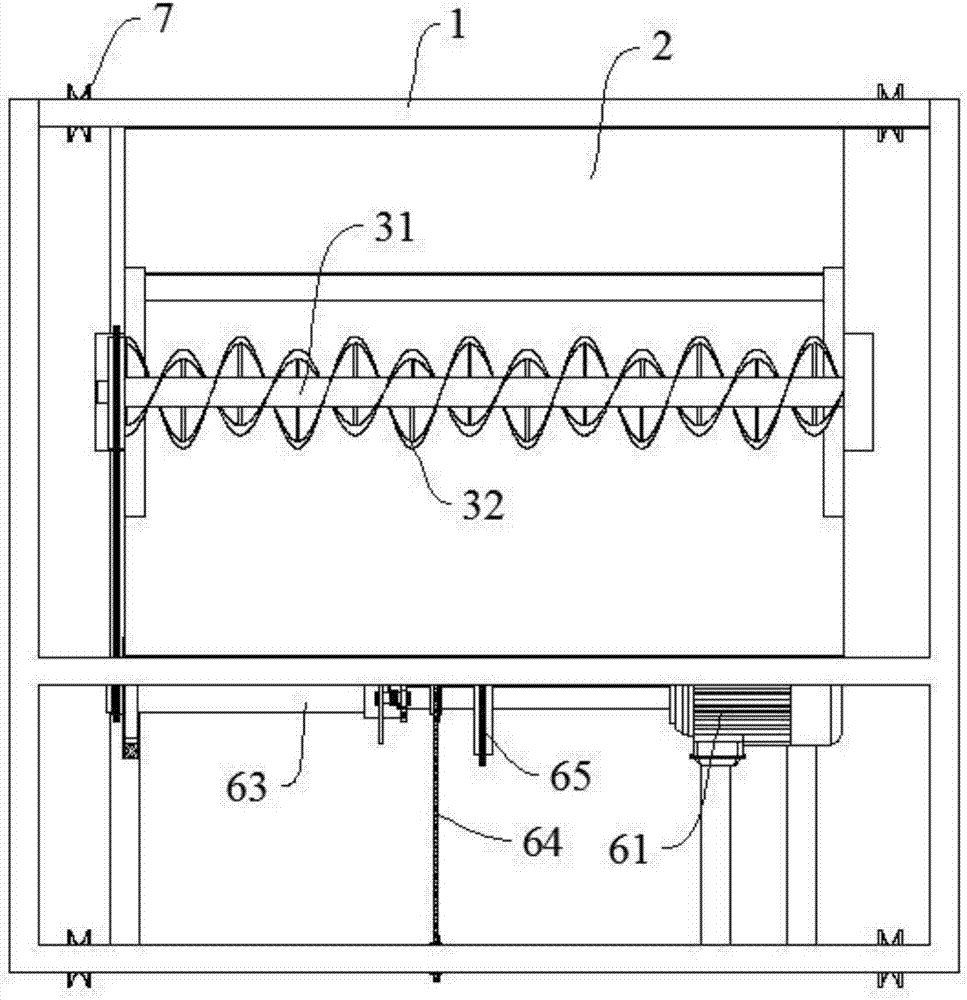

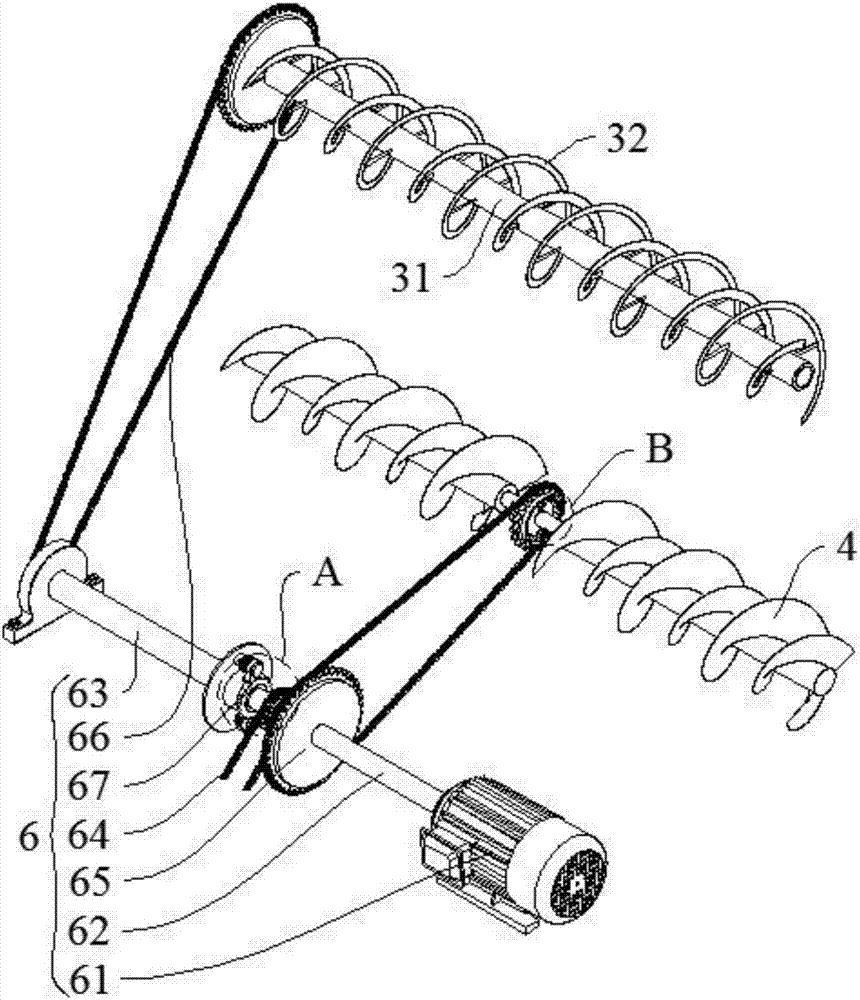

[0021] as attached Figure 1~6 As shown, a feeding machine with visual remote control includes: frame 1, hopper 2, stirring mechanism 3, discharging mechanism 4, water adding system (not shown), gate 5, weighing system (not shown) , camera (not shown), control system (not shown), drive mechanism 6, travel mechanism 7; mixing mechanism 3 is arranged in the middle part of hopper 2, and both sides of hopper 2 bottom have discharge port 21, and discharge mechanism 4 is arranged In the lower part of the hopper 2, a gate 5 is provided between the stirring mechanism 3 and the discharge mechanism 4. When the gate 5 is closed, the hopper 2 is divided into upper and lower parts. When stirring, the gate 5 needs to be closed to prevent the forage from being compacted downward; add water The system is used to add water to the upper chamber of the hopper 2. The traveling mechanism 7 is arranged at the lower part of the frame 1. The driving mechanism 6 provides power for the stirring mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com