Nanometer zinc oxide/porous carbon in-situ composite high-capacity lithium ion battery material and preparation method thereof

An in-situ composite material, nano-zinc oxide technology, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effect of increasing specific surface area, improving electrical conductivity, slowing expansion and shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

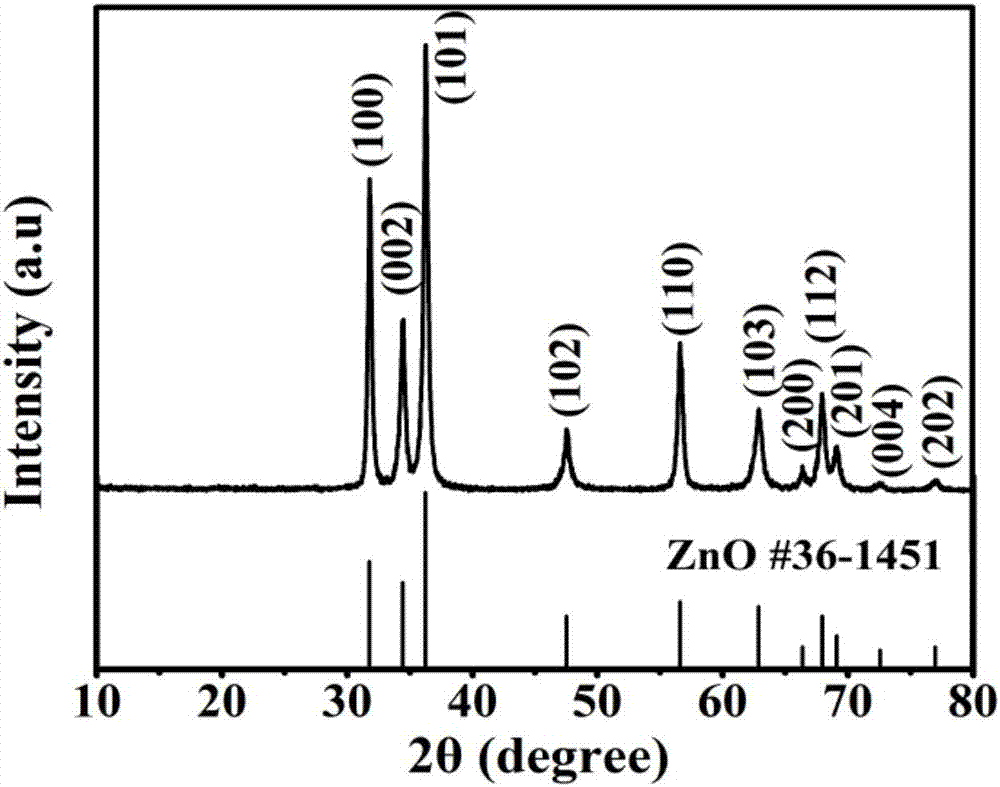

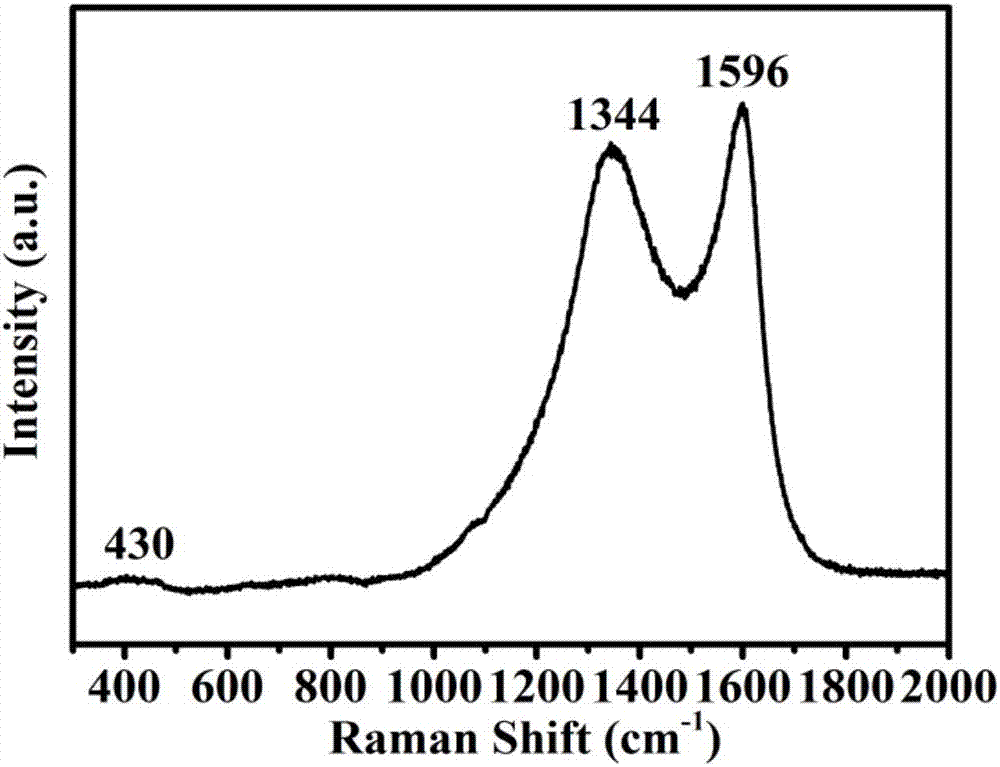

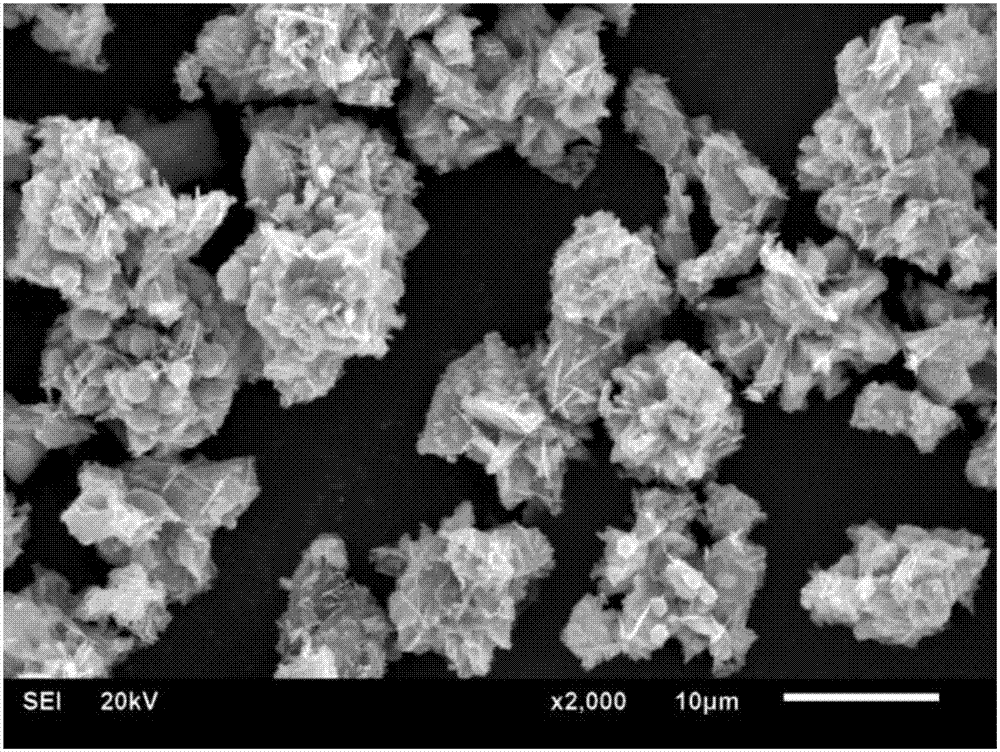

[0028] First, the molar ratio of Zn 2+ :C 6 h 5 o 7 3- Weigh 4.09g of anhydrous zinc chloride and 5.88g of trisodium citrate dihydrate for 3:2, dissolve them in 20mL of deionized water respectively to obtain zinc chloride solution and sodium citrate solution, and mix the two evenly to obtain a mixed solution. Then, the mixed solution with 20 mL of absolute ethanol was placed in a 60°C constant temperature water bath, and kept under stirring reaction conditions for 30 minutes. The obtained reaction precipitate was soaked with absolute ethanol / deionized water for 3 times, and zinc citrate was obtained by freeze-drying. Then put the zinc citrate into the crucible, place it in a horizontal tube furnace, raise it from room temperature to 700ºC at a rate of 5ºC / min under argon gas, keep it warm for 3 hours, and cool it down to room temperature naturally. The final carbonized product is nano Zinc oxide / porous carbon in situ composites.

[0029] The active material is nano zinc o...

Embodiment 2

[0040] First, the molar ratio of Zn 2+ :C 6 h 5 o 7 3- Weigh 4.09g of anhydrous zinc chloride and 5.88g of trisodium citrate dihydrate for 3:2, dissolve them in 20mL of deionized water respectively to obtain zinc chloride solution and sodium citrate solution, and mix the two evenly to obtain a mixed solution. Then, the mixed solution with 20 mL of absolute ethanol was placed in a 60°C constant temperature water bath, and kept under stirring reaction conditions for 10 minutes. The obtained reaction precipitate was soaked with absolute ethanol / deionized water for 3 times, and zinc citrate was obtained by freeze-drying. Then put the zinc citrate into the crucible, place it in a horizontal tube furnace, raise it from room temperature to 600ºC at a rate of 5ºC / min under argon gas, keep it warm for 1h, and cool it down to room temperature naturally, and the final carbonized product is nano Zinc oxide / porous carbon in situ composites.

[0041] The active material is nano zinc ox...

Embodiment 3

[0046] First, the molar ratio of Zn 2+ :C 6 h 5 o 7 3- Weigh 4.09g of anhydrous zinc chloride and 5.88g of trisodium citrate dihydrate for 3:2, dissolve them in 20mL of deionized water respectively to obtain zinc chloride solution and sodium citrate solution, and mix the two evenly to obtain a mixed solution. Then, the mixed solution with 20 mL of absolute ethanol was placed in a 60°C constant temperature water bath, and kept under stirring reaction conditions for 2 hours, and the obtained reaction precipitate was soaked with absolute ethanol / deionized water for 3 times, and zinc citrate was obtained by freeze-drying. Then put the zinc citrate into the crucible, place it in a horizontal tube furnace, raise it from room temperature to 700ºC at a rate of 5ºC / min under argon gas, keep it warm for 2 hours, and cool it down to room temperature naturally. The final carbonized product is nano Zinc oxide / porous carbon in situ composites.

[0047] The active material is nano zinc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Mesopore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com