Organic fertilizer drying device based on centrifugal technology

A drying device and technology for organic fertilizer, applied in drying, dryer, manure drying and other directions, can solve the problems of insufficient sealing, waste of energy, low drying efficiency, etc., to ensure integrity and ensure drying quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

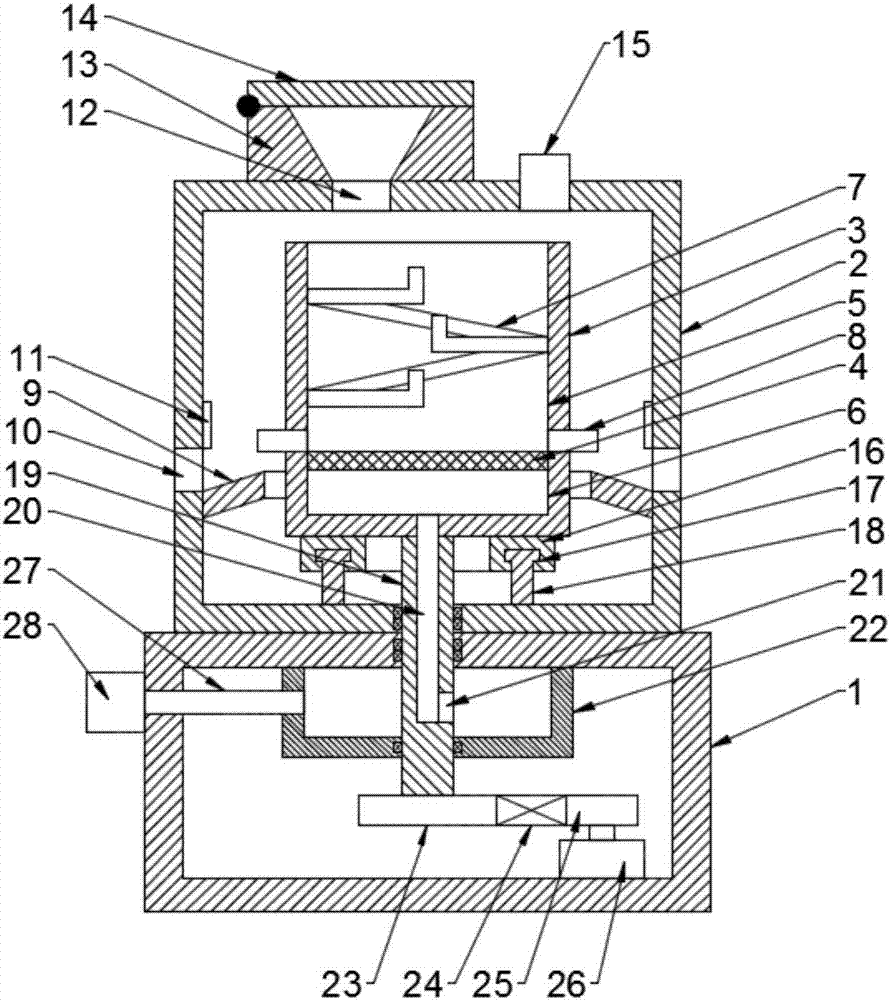

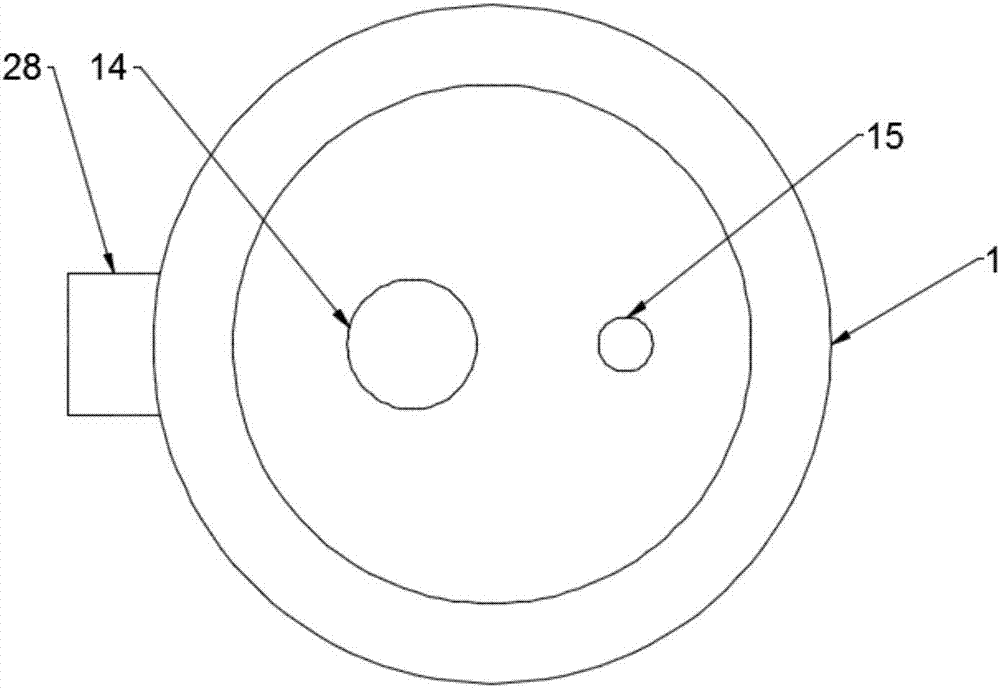

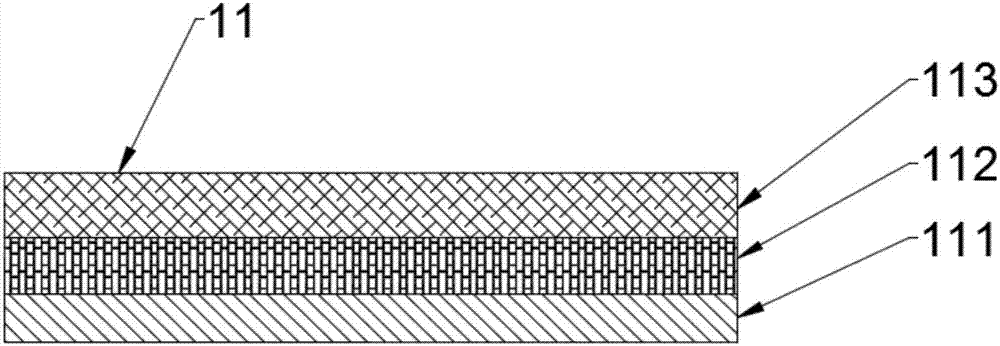

[0019] see Figure 1~3 , an organic fertilizer drying device based on centrifugal technology, comprising a base 1, the top of the base 1 is fixedly connected to a drying box 2, and the drying box 2 is provided with a drying cylinder 3, and the drying cylinder 3 It is a cylindrical structure design with an open top. The bottom of the inner cavity of the drying cylinder 3 is provided with a partition net 4. The partition net 4 is made of metal mesh. The partition net 4 divides the drying cylinder 3 into a drying chamber. 5 and the air distribution chamber 6, the drying chamber 5 is located above the air distribution chamber 6, and the drying chamber 5 is provided with a drying net 7, and the drying net 7 is a space spiral structure design, and the drying The bottom of the side wall of the cavity 5 is evenly connected with a number of discharge pipes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com