Pipeline type fresh air ventilator with variable diameter shell and reducing method of pipeline type fresh air ventilator

A ducted, fresh air fan technology, applied in the field of air purification, can solve the problems of increasing indoor noise, generating vibration, and equipment occupying indoor space, and achieving the effect of saving indoor space, reducing damage, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

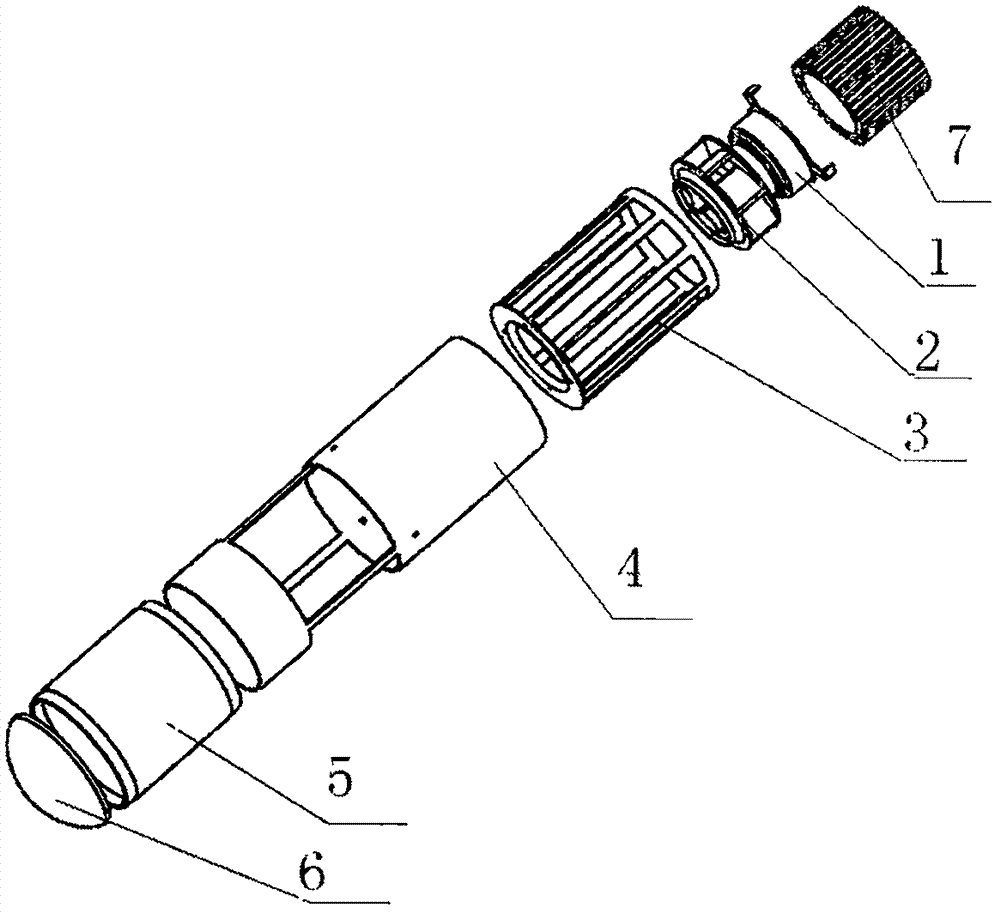

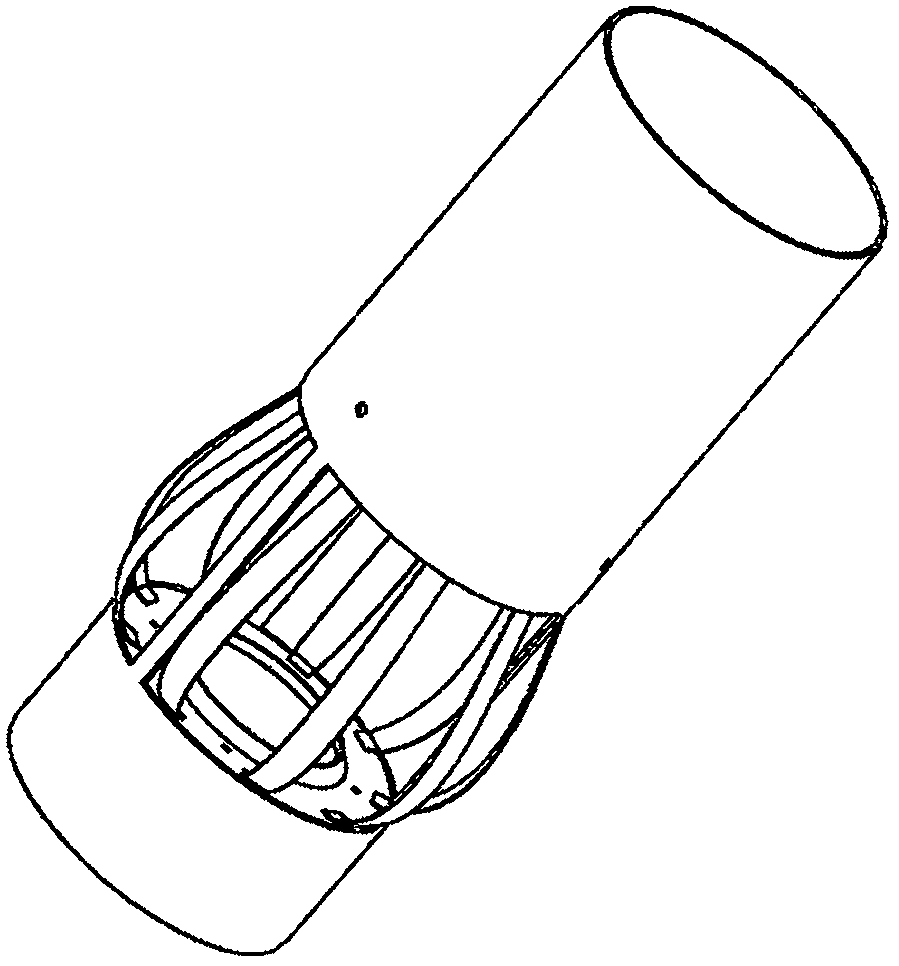

[0035] Such as figure 1 As shown, the ducted fresh air fan with a variable-diameter casing consists of a motor (1), an impeller (2), an elastic frame (3), a cylinder (4), a flexible casing (5), and a coarse-effect filter device (6) , medium and high-efficiency filter device (7); as Figure 4 , 5 As shown, the elastic skeleton (3) is a spherical structure with openings at both ends surrounded by several elastic strip metal sheets, including a fixed end (301), a deformation part (302) and a sliding end (303); Such as Figure 6 As shown, the cylinder (4) is a circular pipe-like structure, including the air inlet end (401) and the air outlet end (403), and the cylinder body (4) has a square opening on the cylinder wall near the air inlet end (401). holes (402); the number of square holes (402) is 2-10, which are evenly distributed on the cylinder body (4) near the air inlet (401) end according to the circumference; as image 3 As shown, the fixed end of the elastic skeleton (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com