Novel low-residual-deformation multiple-yield-point all-steel buckling restrained braces

A multi-yield-point, buckling-constrained technology, applied in the field of new low-residual-deformation-multi-yield-point all-steel buckling-constrained bracing, can solve the problem of failure to meet the repairable performance requirements of bridge structures after earthquakes, large residual deformation between structural layers, and unfavorable engineering Problems such as construction and installation can be improved to improve post-earthquake repairability, low rigidity, and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

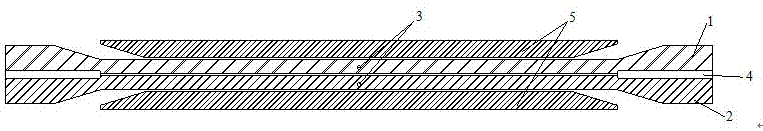

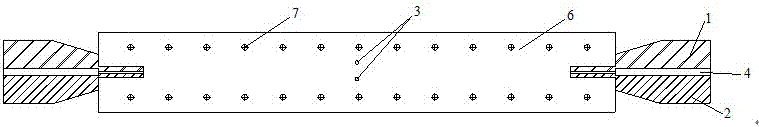

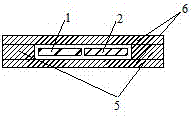

[0018] Embodiment 1: with figure 1 An example of a multi-yield-point buckling-restrained brace with low residual deformation is shown, as described in this patent. The core material is composed of a steel core material 2 with a low yield point and a high-strength steel core material 1, and is supported on the left and right sides by a restraint plate 6. The filler plate 5 and the restraint plate 6 are connected by high-strength bolts 7, and the core The timber is wrapped in the filler panel 5 and the restraint panel 6 . The assembly process is as follows: first place the core material and the constraining plate 6 on the same plane, the constraining plate 6 supports the left and right sides of the core material, and then use the high-strength bolts 7 to make the filler plate 5 cover the upper and lower sides of the core material, It is also connected with the constraining plate 6 to finally form a whole.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com