Foundation of assembly-decoration integrated building with light-weight steel structure, and construction method thereof

A light steel structure and construction technology, which is applied in basic structure engineering, construction, excavation, etc., can solve the problems of adverse impact on the original ecological environment of the construction site, positioning errors of the column anchor bolts, and large workload, etc., to shorten the construction period, reduce Workload, low impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings of the specification:

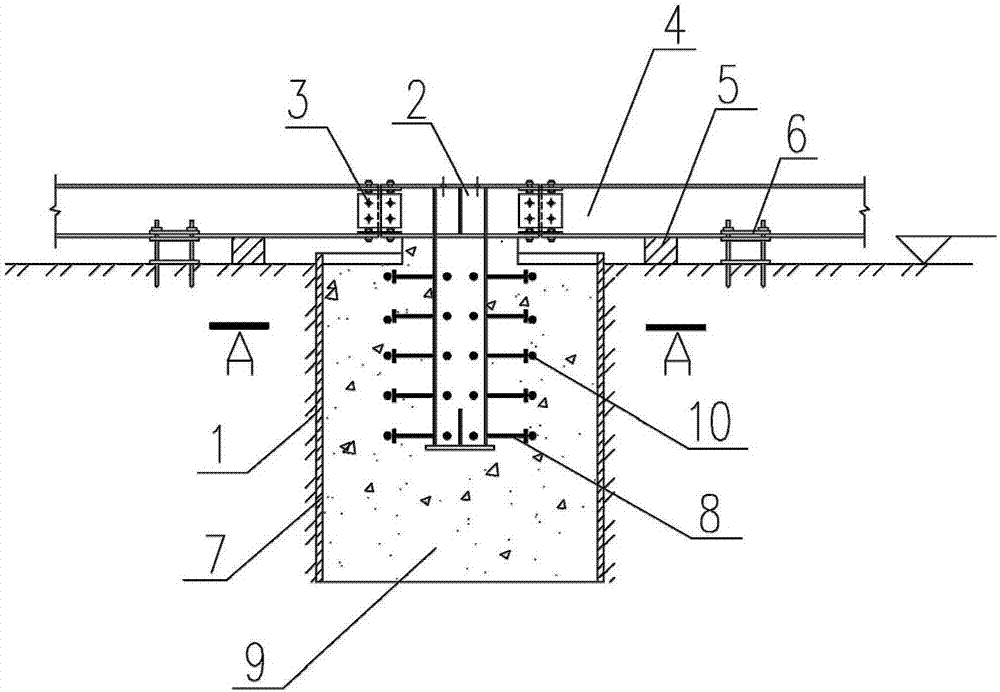

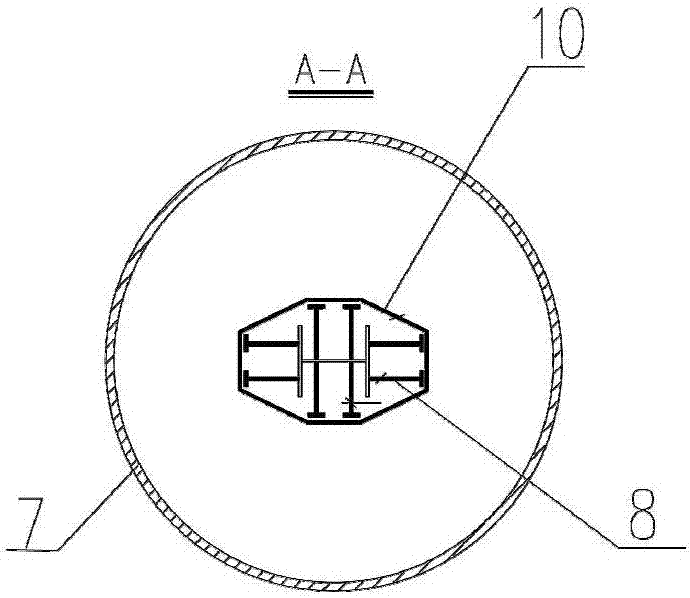

[0023] Such as figure 1 with figure 2 As shown, the foundation of a light steel structure assembly and decoration integrated building of the present invention is characterized in that it includes a foundation pit 1, a foundation pit retaining wall 7 arranged on the inner wall of the foundation pit 1, and a concrete 9 poured in the foundation pit 1. The profiled steel pedestal 2 embedded in the concrete 9. The said foundation pit retaining wall 7 is a thin-plate cylindrical retaining wall. The material of the retaining wall is steel or other environmentally friendly materials. The said profiled steel pedestal 2 is welded with steel on all four sides. Column studs 8, and the profiled steel pedestals with steel bars 10 are circumferentially welded to the caps of the steel studs 8; the lower part of the profiled steel studs 2 is buried in the concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com