Cloth swinging device on side of dyeing machine

A dyeing machine and cloth board technology, applied in the field of dyeing machines, can solve problems such as affecting dyeing quality, unsmooth running and knotting, etc., to ensure the effect of water separation, improve running state, and reduce liquor ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

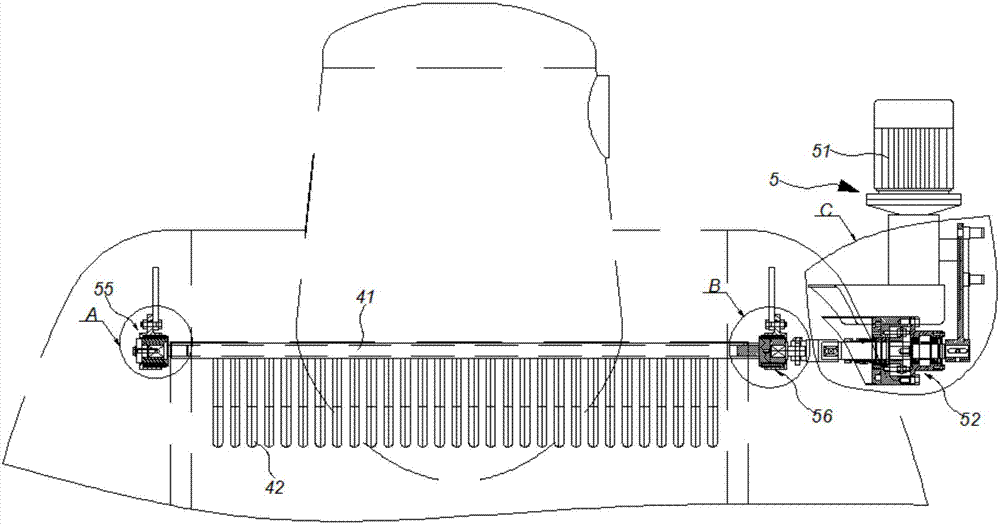

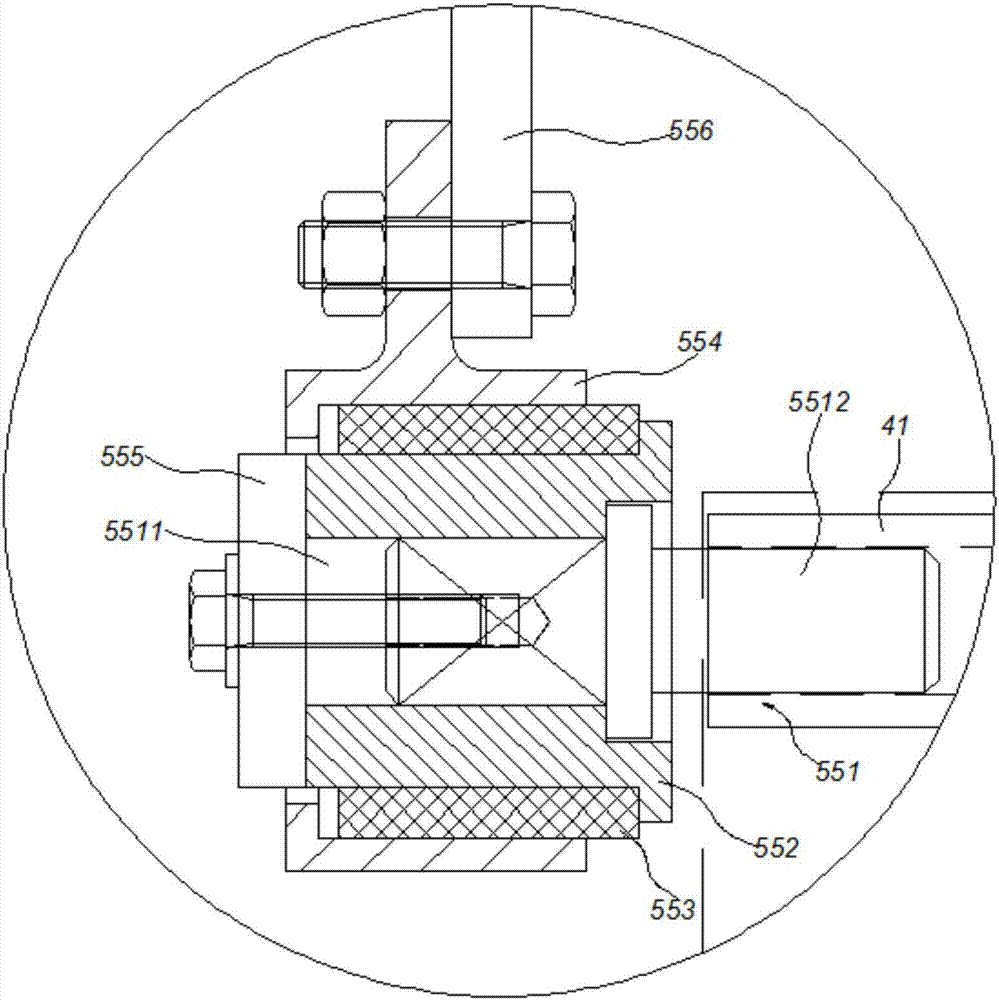

[0023] like figure 1 , 5 As shown, the arrangement device on the side of the dyeing machine includes a cylinder body 1, a cloth storage tank 2, a cloth guide pipe 3, a cloth flap 4 and a swing mechanism 5, and the cloth storage tank 2, cloth guide pipe 3, and cloth flap 4 are built into the cylinder body 1. The output end of the cloth guide pipe 3 is placed in the cloth storage tank 2 opposite to the cloth flap 4. The cloth clapping plate 4 includes a main shaft 41 and pipe teeth 42. The main shaft 41 is arranged along the left and right directions of the cloth storage tank 2. A plurality of parallel pipe teeth 42 are arranged below the main shaft 41, preferably 30. Between adjacent pipe teeth 42 The pitch is 5 mm to 35 mm, preferably 15 mm.

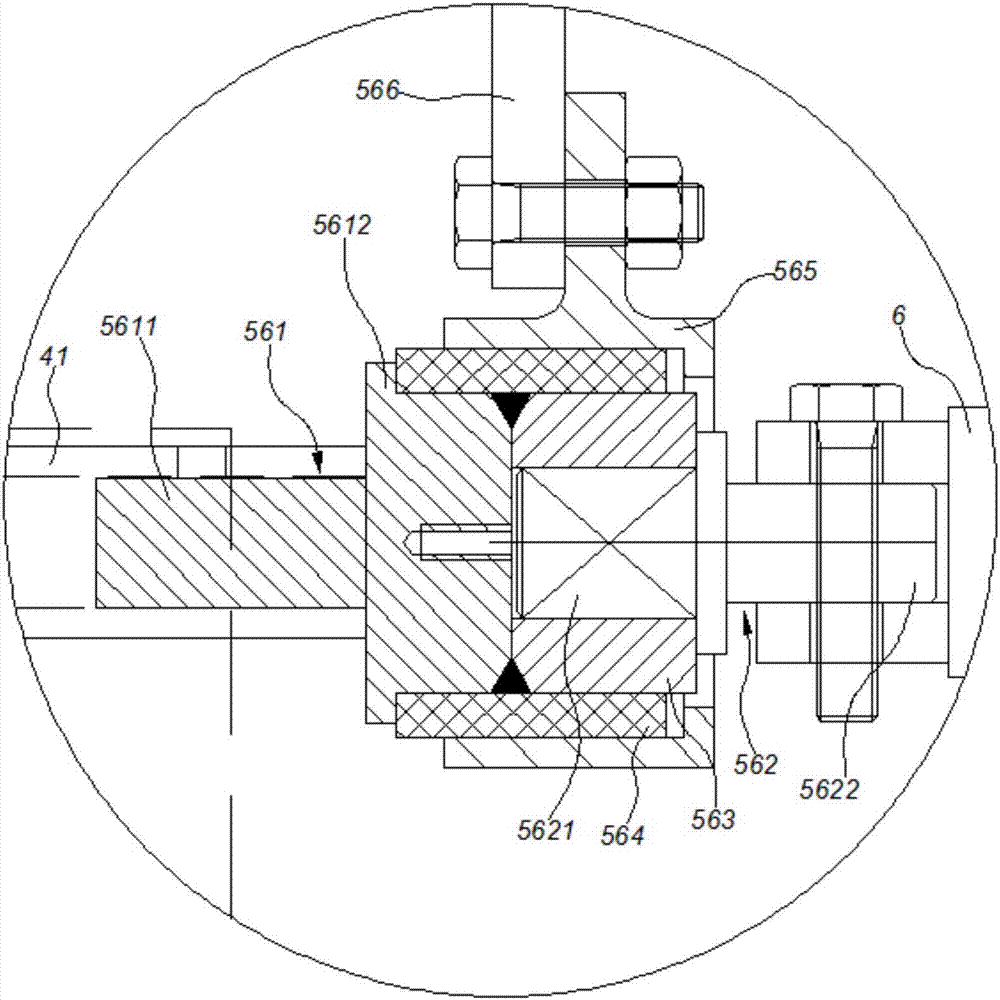

[0024] like figure 1 , 4 , 5, the swing mechanism 5 includes a reduction motor 51, a side swing shaft combination 52 and a linkage mechanism 53, the reduction motor 51 is a spur gear reduction motor, the reduction motor 51 is install...

Embodiment 2

[0030] like Figure 6 , 7As shown, the difference between this embodiment and Embodiment 1 lies in the link mechanism 53. The link mechanism 53 of this embodiment includes a second crank 53a, a pull rod 53b, a second rocker 53c, a third rocker 53d, a second Connecting rod 53e and the 4th rocking bar 53f, reduction motor 51 are connected second crank 53a by A-type round head common flat key, the rear end of pull rod 53b is connected second rocking bar 53c by anti-thread nut, ball bearing, and the rear end of pull rod 53b The front end is connected to the second crank 53a through a straight tooth nut and a ball bearing, and the second rocker 53c is connected to the right end of the rotating shaft 52a through an A-type round head common flat key. The third rocker 53d is connected to the left end of the rotating shaft 52a through the first inner eccentric rod 53g, the third rocker 53d and the fourth rocker 53f are connected through the second connecting rod 53e, and the fourth ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com