Preparation method of flame-retardant polyhydric alcohol and polyurethane foam and polyurethane sealant prepared from flame-retardant polyhydric alcohol

A technology of polyurethane sealant and flame retardant polyol, applied in the field of polyurethane foam and polyurethane sealant, can solve the problems of poor flame retardant performance of inorganic flame retardants, less application, affecting the mechanical properties of polyurethane sealants, etc. Wide application prospect and rich output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

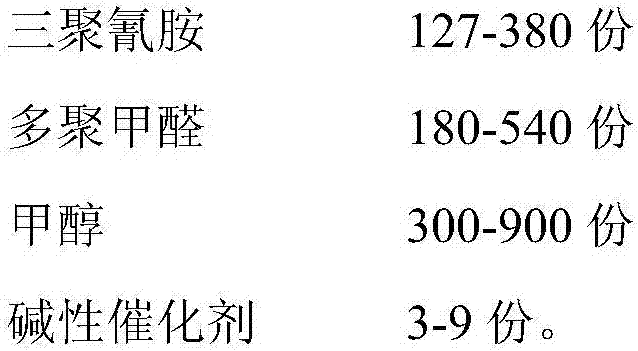

[0043] Weigh 127 parts by mass of melamine, 180 parts by mass of paraformaldehyde, 300 parts by mass of methanol, and 3 parts by mass of sodium hydroxide catalyst, heat up to a temperature of 70°C, and react for 2 hours. After the reaction is complete, add acid to adjust to pH=4 -5, add 198 parts by mass of tetrakis hydroxymethyl phosphorus chloride, react at 50°C for 3h, adjust to pH=8-10 with water and alkali catalyst, then add 900 parts by mass of castor oil, and reduce the temperature at 60-110°C Remove water and methanol under pressure, raise the temperature to 110°C to remove water and methanol under reduced pressure for 3 hours, reduce the water content to ≤0.5%, and filter with suction to obtain a light yellow transparent liquid.

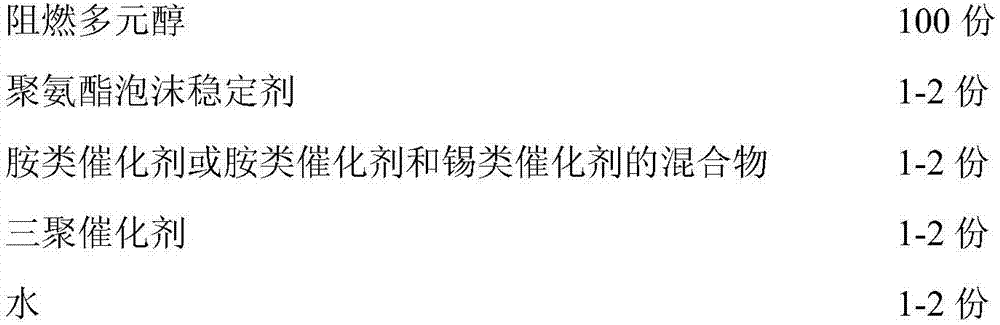

[0044] Mix the bio-based castor oil flame retardant polyol and foaming agent evenly, then add amine catalyst or the mixture of amine catalyst and tin catalyst, polyurethane foam stabilizer, trimerization catalyst, water, and stir evenly to ob...

Embodiment 2

[0047] Weigh 152 parts by mass of melamine, 216 parts by mass of paraformaldehyde, 360 parts by mass of methanol, and 3.6 parts by mass of sodium hydroxide catalyst, heat up to a temperature of 72°C, and react for 2.5 hours. After the reaction is complete, add acid to adjust the pH to 4-5, add 237 parts by mass of tetrakis hydroxymethyl phosphorus chloride, react at 52°C for 3 hours, adjust to pH = 8-10 with water and alkali catalyst, then add 900 parts by mass of castor oil, at 60-110°C Remove water and methanol under reduced pressure, raise the temperature to 110° C., remove water and methanol under reduced pressure for 3 hours, reduce the water content to ≤0.5%, and filter with suction to obtain a light yellow transparent liquid.

[0048] Mix the bio-based castor oil flame retardant polyol and foaming agent evenly, then add amine catalyst or the mixture of amine catalyst and tin catalyst, polyurethane foam stabilizer, trimerization catalyst, water, and stir evenly to obtain ...

Embodiment 3

[0051] Weigh 177 parts by mass of melamine, 252 parts by mass of paraformaldehyde, 420 parts by mass of methanol, and 4.2 parts by mass of sodium hydroxide catalyst, heat up to a temperature of 74°C, and react for 2.5 hours. After the reaction is complete, add acid to adjust the pH= 4-5, add 277 parts by mass of tetrakis hydroxymethyl phosphorus chloride, react at 54°C for 3 hours, adjust to pH = 8-10 with water and alkali catalyst, then add 900 parts by mass of castor oil, at 60-110°C Remove water and methanol under reduced pressure, raise the temperature to 110° C., remove water and methanol under reduced pressure for 3 hours, reduce the water content to ≤0.5%, and filter with suction to obtain a light yellow transparent liquid.

[0052] Mix the bio-based castor oil flame retardant polyol and foaming agent evenly, then add amine catalyst or the mixture of amine catalyst and tin catalyst, polyurethane foam stabilizer, trimerization catalyst, water, and stir evenly to obtain co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com