an angle gauge

An angle gauge and angle technology, which is applied in the direction of manufacturing tools, other manufacturing equipment/tools, grinding/polishing equipment, etc., can solve the problems of not being able to obtain the sharpening angle, non-slip, and difficult to grasp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

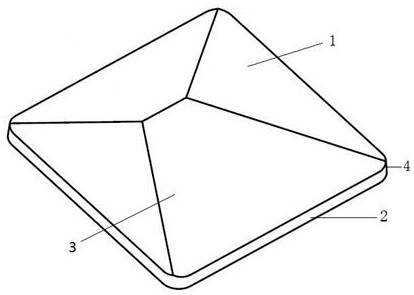

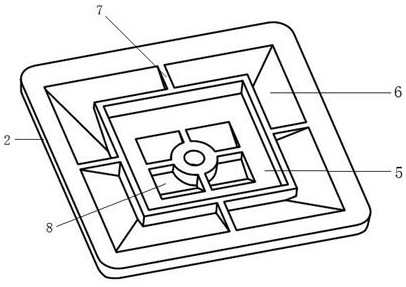

[0027] Specific embodiment 1, see figure 1 with figure 2 , The present invention provides an angle gauge, which includes a top 1, a bottom 2 below the top and a groove 5 provided at the bottom; the top 1 is spliced by four inclined surfaces 3, and the inclined angles of the inclined surfaces are multiple Different angles are 14°, 17°, 20°, 25°. The lower end of the inclined surface 3 is connected with the outer edge of the bottom 2, and the outer edge of the bottom is provided with a chamfer 4. At the beginning of sharpening the blade, fingers can be placed on other slopes other than the positioning slope actually used for sharpening the blade, and by pressing the angle gauge, the adhesion between the angle gauge and the metal grindstone substrate is strengthened.

[0028] The top 1 and the bottom 2 are integrally formed of the same material.

[0029] The concave part of the bottom 2 is hollowed out 6 and has a reinforcing rib 7 for connecting the bottom 2 and the groove 5.

[00...

specific Embodiment 2

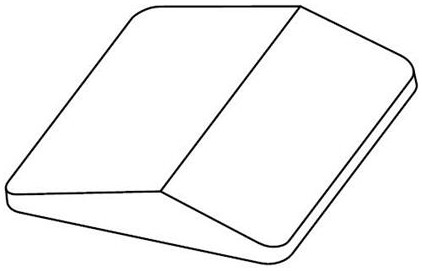

[0032] Specific embodiment 2 is basically the same as embodiment 1, see image 3 , The top part is formed by splicing two inclined surfaces, and the inclined angles of the inclined surfaces are two different angles.

[0033] The top and bottom are connected and fixed by pasting.

[0034] The groove is equipped with a magnet, and the depth of the built-in surface of the groove is the same as the thickness of the magnet.

specific Embodiment 3

[0035] Specific embodiment 3 is basically the same as embodiment 1, see Figure 4 , The top part is spliced by three inclined surfaces, and the inclined angles of the inclined surfaces are three different angles.

[0036] The top and bottom are fixed by screws.

[0037] The groove is equipped with a magnet, and the depth of the built-in surface of the groove is the same as the thickness of the magnet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com