Oil pressure ankle joint

An ankle joint, hydraulic technology, applied in the direction of ankle joint, joint implants, joint implants, etc., can solve the problems of difficult maintenance, inconvenient use, complex internal components of the structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

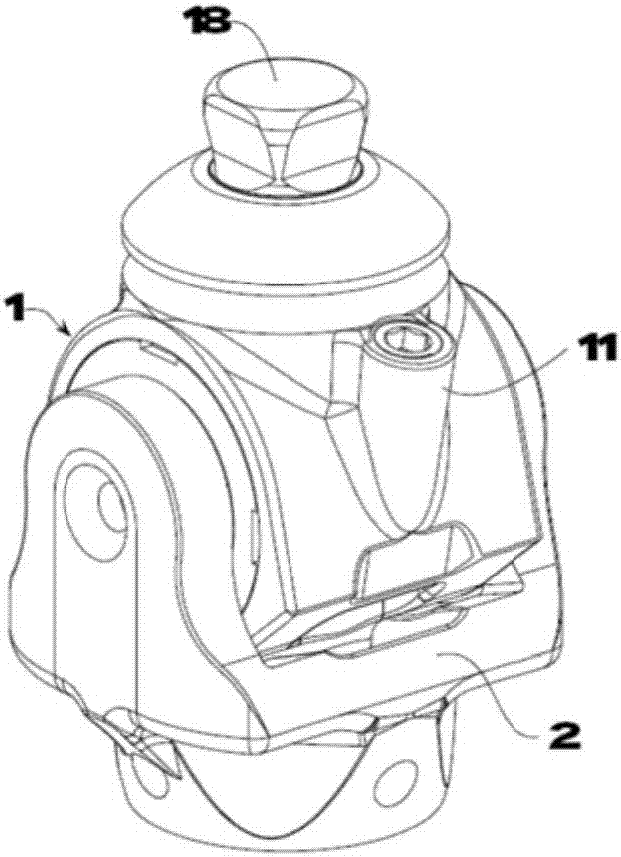

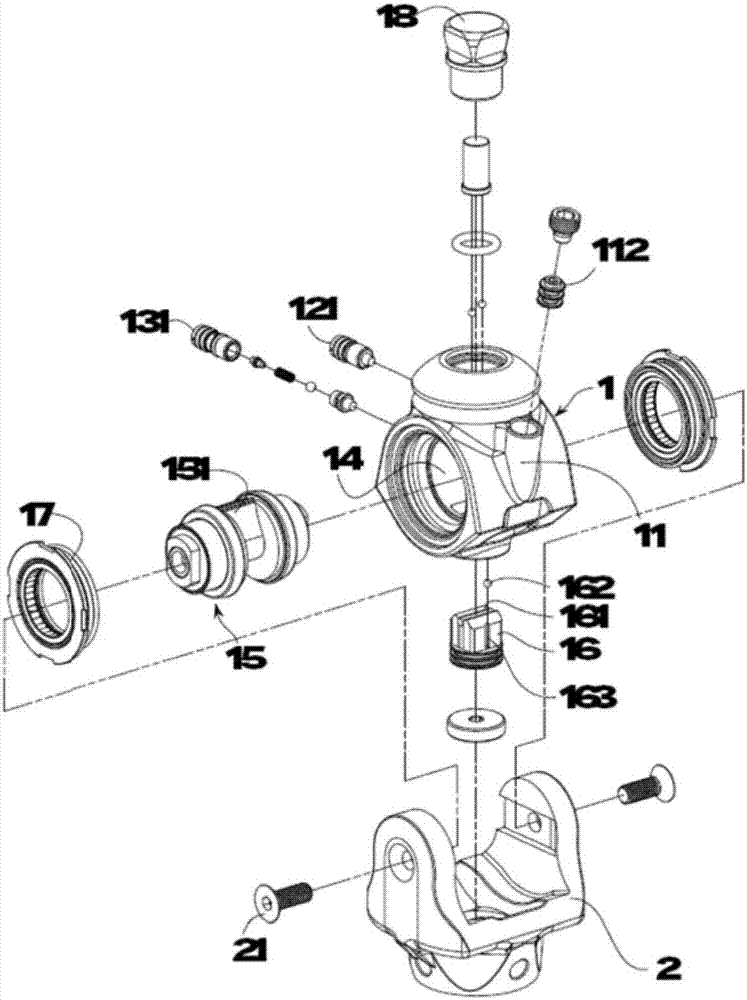

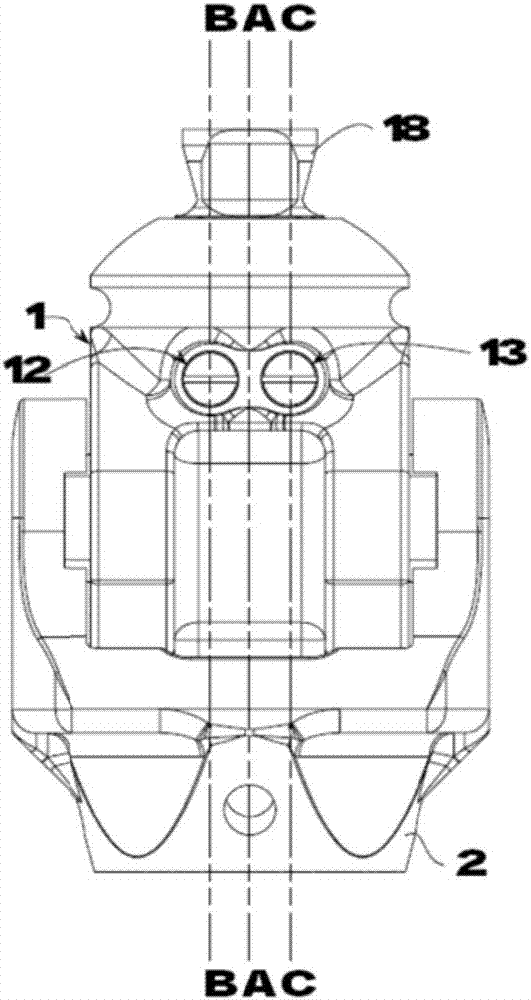

[0028] Generally according to the present invention, the best available embodiment, and cooperating Figure 1 to Figure 7 After being described in detail, the understanding of the present invention can be increased. The present invention is a kind of hydraulic ankle joint, which has an ankle hydraulic cylinder 1 in its structure, and a bearing 18 is provided on the top to connect other prosthetic parts, and the bottom is a Equipped with a prosthetic foot 3 for use, the foot and ankle hydraulic cylinder 1 has an oil replenishment chamber 11, a first pressure regulating chamber PF12, a second pressure regulating chamber DF13, and a housing connected to the above-mentioned chambers. space 14, the oil supply chamber 11 is set on one side of the ankle hydraulic cylinder 1, and the first pressure regulating chamber PF12 and the second pressure regulating chamber DF13 are set on the other side of the ankle hydraulic cylinder 1, in coordination with image 3 As shown by the section li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com