Enterprise safety production integrated management system and method

A technology of safe production and comprehensive management, applied in the field of information management, can solve the problems of inability to apply linkage management, error prevention and leakage repair in a timely and efficient manner, and achieve the goal of reducing the probability of accidents and the severity of consequences, avoiding incoherence, and realizing informationization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

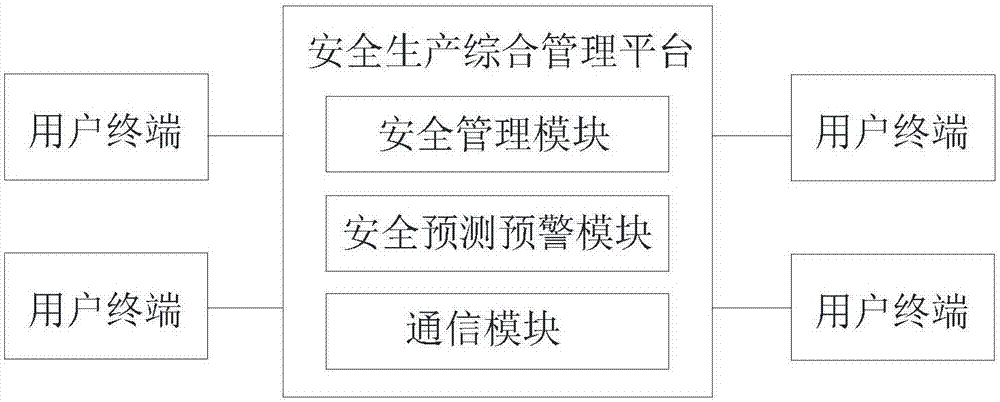

[0083] An enterprise safety production comprehensive management system, such as figure 1 As shown, it includes a production safety comprehensive management platform and several user terminals connected to the production safety comprehensive management platform;

[0084] The integrated safety production management platform includes:

[0085] Security management module: used to receive the security management information sent by the user terminal, and perform corresponding calculation evaluation or / and statistical analysis;

[0086] Safety prediction and early warning module: used to evaluate the safety production status, generate and issue safety production early warning signals;

[0087] Communication module: used for information interaction between the integrated safety production platform and user terminals.

[0088] In this embodiment, the employees of the enterprise directly enter or import the relevant information of the safety management in charge of their posts direct...

Embodiment 2

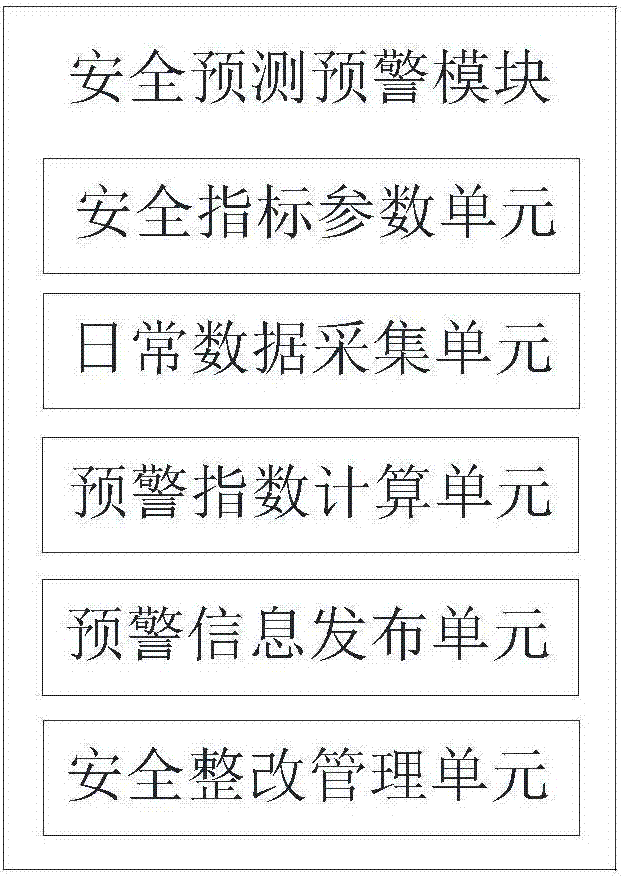

[0091] An enterprise safety production comprehensive management system, different from Embodiment 1, such as figure 2 As shown, the safety prediction and early warning module includes:

[0092] Safety index parameter unit: used to set safety index parameter types and evaluation scores;

[0093] Daily data collection unit: used to collect data of safety index parameters;

[0094] Early warning index calculation unit: used to calculate the safety early warning index according to the following formula and divide the safety production early warning status according to the calculation results;

[0095] SPI=∑k j x j

[0096] Among them: SPI is the safety warning index, X j is the data of the jth safety index parameter, k j is the correction parameter of the jth safety index parameter.

[0097] Early warning information release unit: used to release early warning information;

[0098] Security rectification management unit: used to manage the status of security rectification...

Embodiment 3

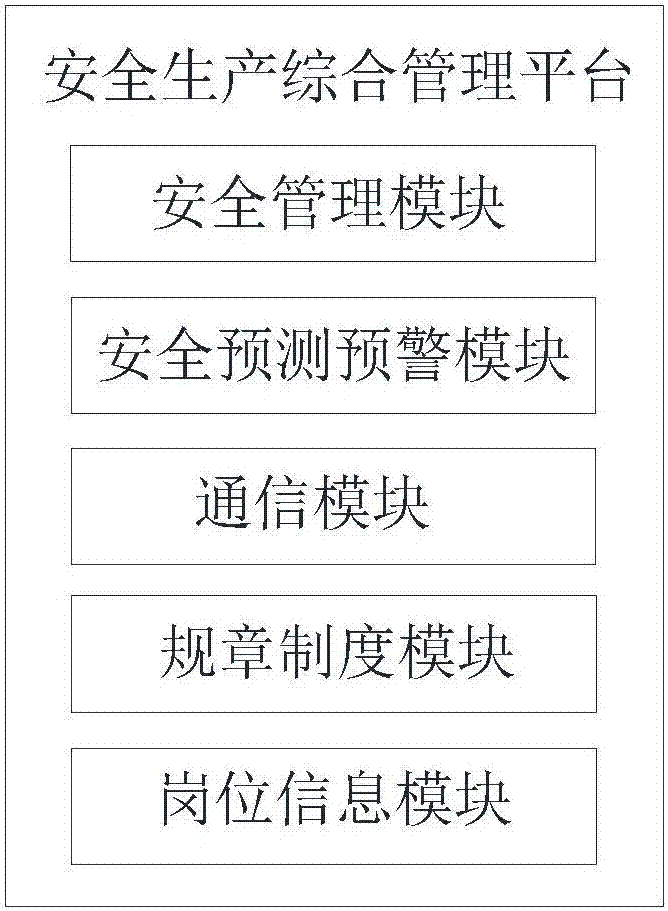

[0104] An enterprise safety production comprehensive management system, different from Embodiment 1, such as image 3 As shown, the integrated safety production management platform also includes:

[0105] Rules and regulations module: used for user terminals to enter, maintain and query laws, regulations and normative standards;

[0106] Job information module: used for user terminals to enter and manage enterprise job personnel information.

[0107] The position information module maintains and manages the basic information of personnel and professional qualification certificates, and builds an enterprise archives of on-the-job personnel, which can realize fuzzy query of names, reminders of professional qualification certificate expiration, and lay the foundation for safety management; The retrained personnel provide a reminder of the validity period of the certificate to help the company quickly update the file information of unqualified and expired personnel. At the same t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com