Ultrasonic sensor

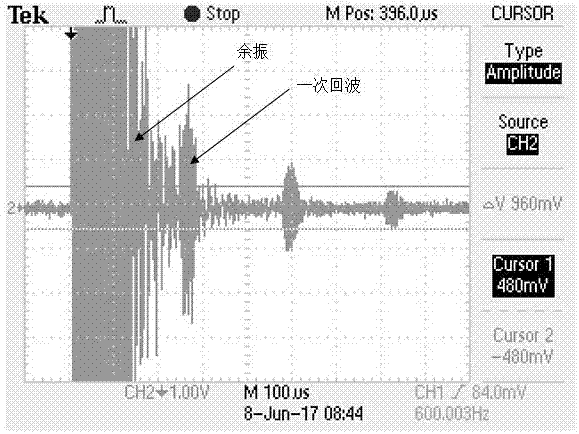

A sensor and ultrasonic technology, which is applied in the field of ultrasonic sensors, can solve the problems of performance degradation, structural influence, poor effect, etc., and achieve the effect of greatly reducing aftershock, simple structure, and improving echo sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Such as figure 2 As shown, the ultrasonic sensor of the present invention includes a housing 1 and a piezoelectric wafer 2 placed in the housing, a base 3 is installed at one end of the housing, and a flexible glue 5 is fixed on the side of the piezoelectric wafer facing the base. The other side is fixed with a matching layer 4 . During specific implementation, the following steps are included.

[0021] The first step is to use epoxy with a density of 1.16 as the carrier, add glass beads and curing agent according to the ratio of epoxy: glass beads: curing agent = 1: (0.65-0.75): (0.4-0.5), and then press the ring Oxygen: epoxy silane coupling agent = 1: (0.010 ~ 0.013) Add epoxy silane coupling agent and vacuumize and stir until uniform to form a paste-like matching layer material.

[0022] In the second step, the shell and wafer are fixed with a special tooling fixture. Ensure that the wafer is placed in the middle of the housing, and the distance from the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com