Gypsum board wall cleaning device for building construction

A technology for building construction and cleaning devices, applied in construction, building maintenance, building construction, etc., can solve the problems of complicated cleaning process, inconvenient transportation, easy to break gypsum, etc., and achieve simple cleaning process, easy transportation, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

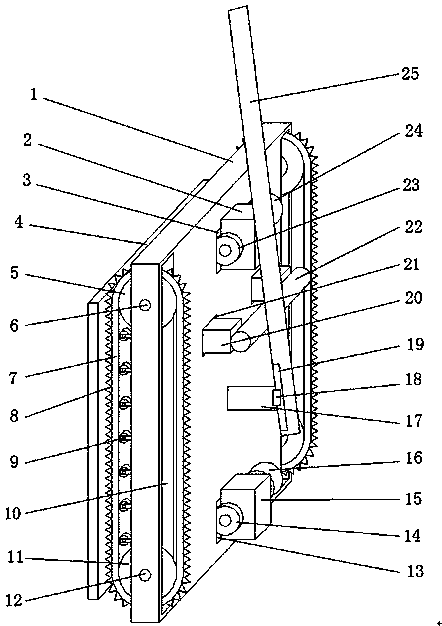

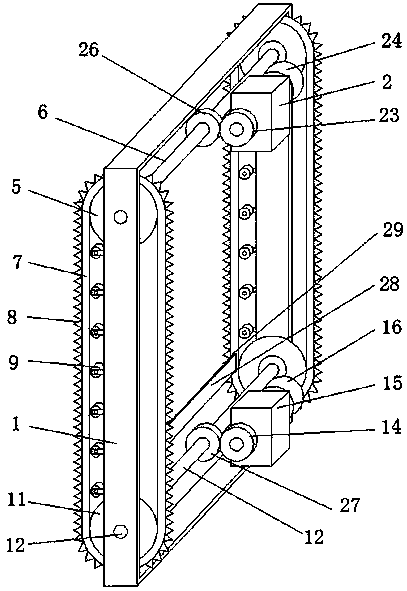

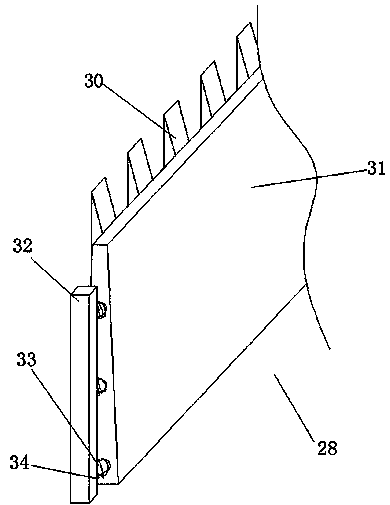

[0032] see Figure 1-6, a gypsum board wall cleaning device for building construction, comprising a close-fitting plate 4, a symmetrical stable slide bar 20 is fixedly connected to the close-fitting plate 4, and a clearing operation panel 1 is slidably connected to the firm slide bar 20, and the clearing operation panel 1 is provided with a stable sliding hole 21 corresponding to the stable sliding bar 20, and one end of the two stable sliding bars 20 away from the close-fitting plate 4 is fixedly connected through the operating handle bar 22, and the operating handle bar 22 is rotated and connected with an operating lever 25. The short end of the lever 25 is connected with a push rod 17, and the end of the push rod 17 away from the operating lever 25 is fixedly connected on the clearing operation panel 1, and the upper driving rotating shaft 6 and the lower driving rotating shaft 12, which are rotationally connected symmetrically on the clearing operating panel 1, clear the op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com