Prefabricated plate beam erecting method

A prefabricated panel and truss technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of high use and rental costs, cumbersome installation and disassembly process, affecting the speed of bridge erection, etc., to save construction period and erection process. Simple and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

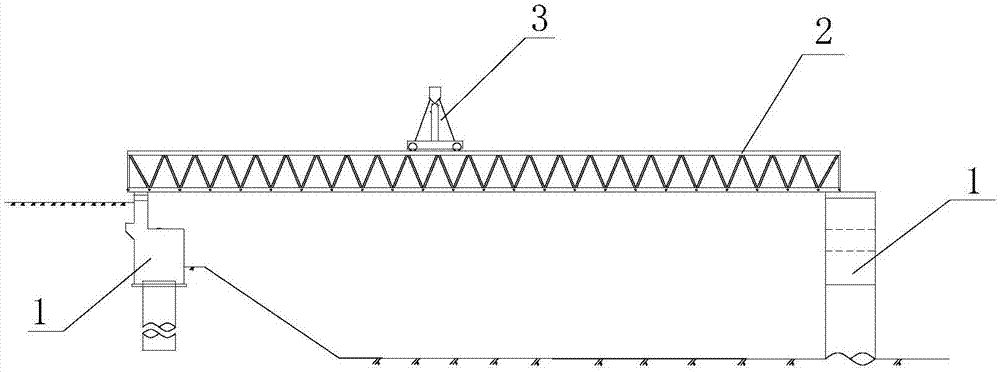

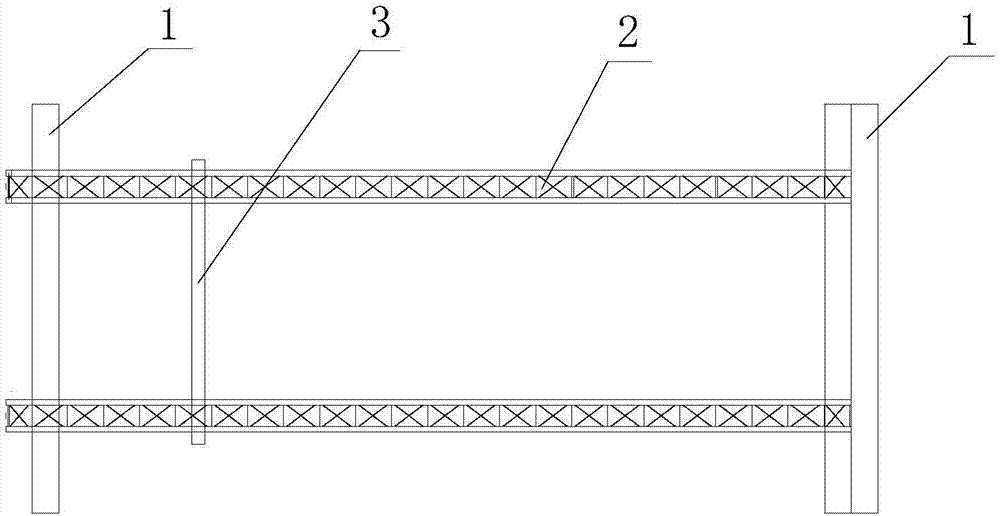

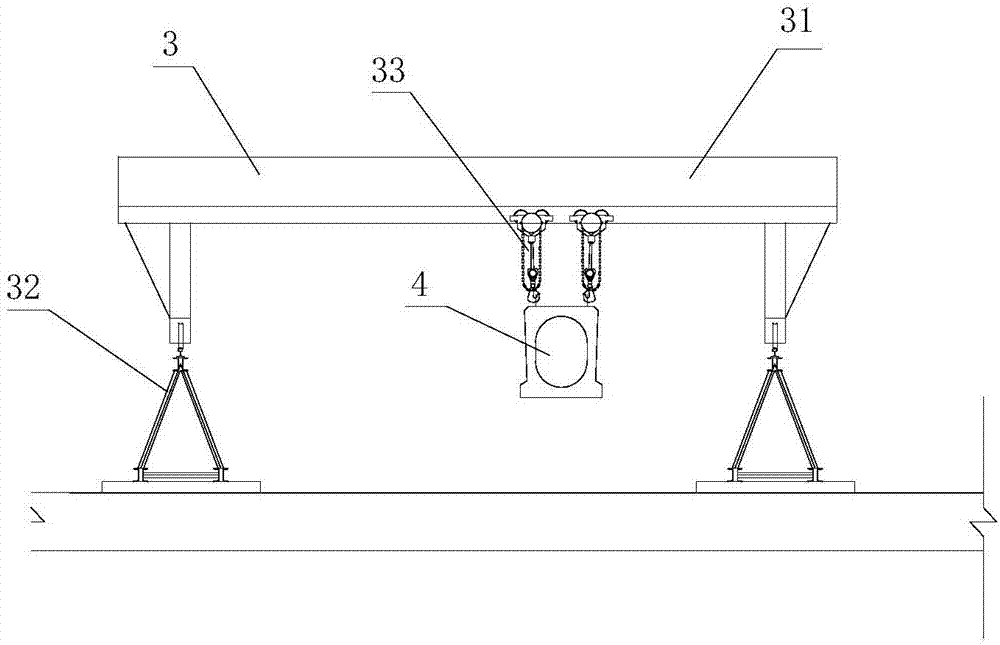

[0043] The present invention provides a method for erecting a prefabricated slab girder, which is used for the construction of a bridge whose deck is a prefabricated slab girder 4. Specifically, during the erection process of the prefabricated slab girder 4, the prefabricated slab girder 4 is moved along the bridge construction direction from the first The first position is moved to the second position and positioned. In actual erection, after the erection of the prefabricated slab girder 4 is completed, the prefabricated slab girder 4 is located on a span of the bridge, that is, one end of the prefabricated slab girder 4 is located in the adjacent pier 1 On one pier 1, the other end is located on another pier 1 among the adjacent pier 1, and the construction direction is from the bridge head to the center of the bridge when the bridge is erected. The second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com