Oscillating diode electroplating machine

A technology of electroplating machine and diode, applied in the direction of circuit, electrolytic process, electrolytic components, etc., can solve the problems of unqualified quality, bent lead wire of diode, unstable coefficient of variation of diode, etc., and achieve the effect of uniform plating thickness and low coefficient of variation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

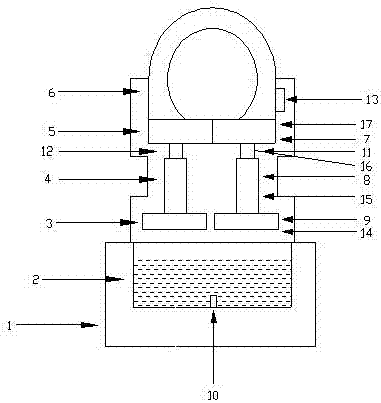

[0012] Attached below figure 1 The present invention will be further described with specific embodiments.

[0013] like figure 1 Shown, the present invention: the oscillating diode electroplating machine is composed of electroplating machine body 1, electroplating tank 2, variable resistance box 13, hydraulic lifting shaft 16, oscillator 17, transmission vibration shaft 16, oscillating electroplating motor 6, vibrating screen 14 and Composed of conductive nails 10, it is characterized in that: the lower end of the electroplating machine body 1 is provided with an electroplating tank 2, the bottom of the electroplating tank 2 is provided with a conductive nail 10, and the upper end of the electroplating machine body 1 is provided with an oscillating electroplating motor 6. The motor 6 is fixedly connected to the oscillator 17, the lower end of the oscillator 17 is connected to the upper end of the hydraulic lifting shaft 16, the lower end of the hydraulic lifting shaft 16 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com