Method for preparing high-purity eugenol epoxy, product and application of product

A technology of eugenol epoxy and eugenol, which is applied in the field of preparation of high-purity eugenol epoxy, can solve the problems that eugenol epoxy affects processing and utilization, and impurity is difficult to purify, etc., so as to improve compatibility, improve purity, and improve Effects of Modification Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

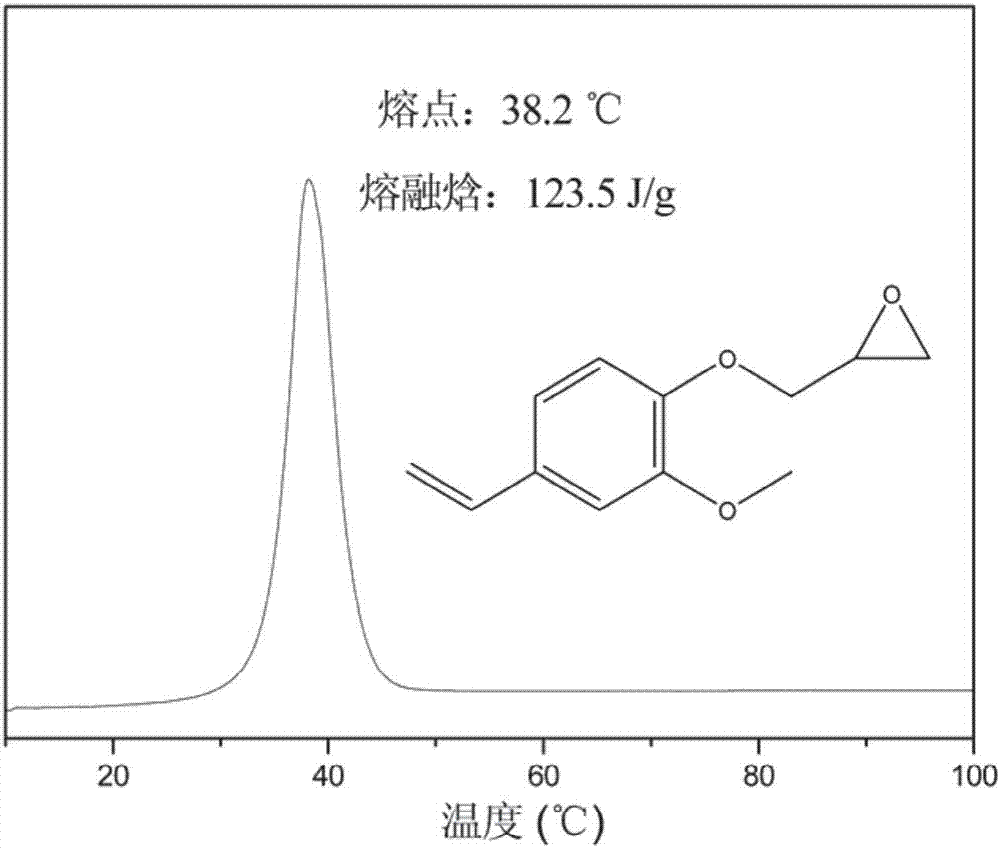

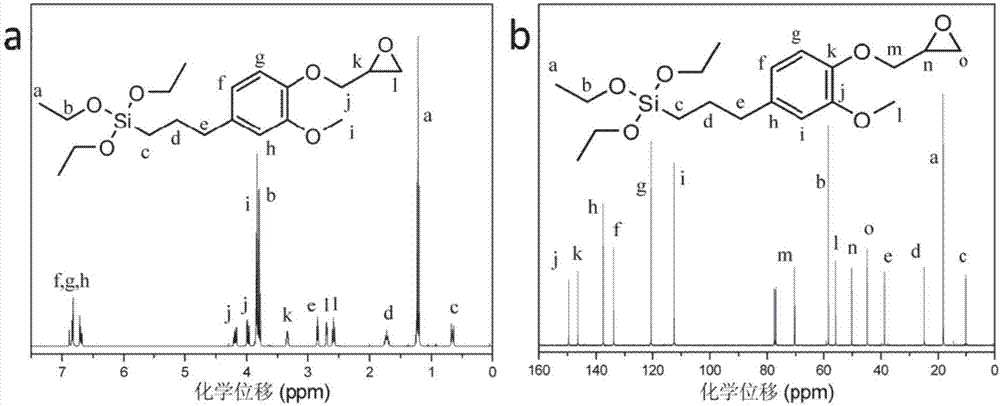

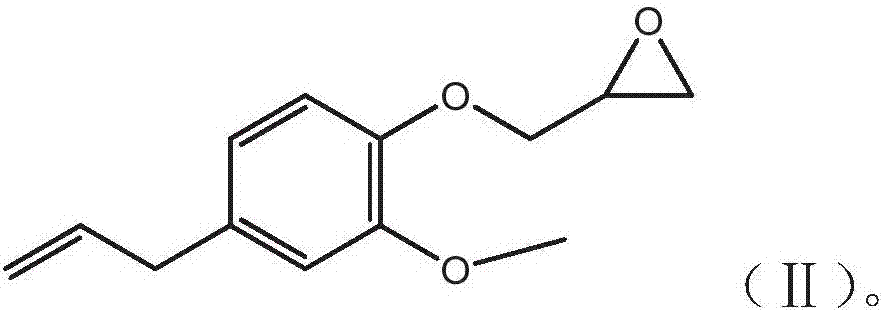

Embodiment 1

[0038] 350 g of epichlorohydrin and 100 g of eugenol were mixed to obtain a mixed solution, and 3.5 g of benzyltriethylammonium chloride was added to the mixed solution, and the temperature was raised to 110° C. for 2 hours to react. Then, 135 g of 20% aqueous sodium hydroxide solution was added dropwise within 5 hours, and the reaction was continued at 110° C. for 5 hours to obtain a crude product. After washing the crude product three times with water, the excess epichlorohydrin was removed by vacuum distillation to obtain the crude product, and then the crude product was mixed with methanol, cooled to -5°C and filtered to obtain eugenol epoxy, which was tested by NMR. The purity was 98%, and the yield was 82%.

Embodiment 2

[0042] The preparation process is the same as in Example 1, the only difference being that two low-temperature recrystallization processes are adopted, and the same process conditions are used twice. After nuclear magnetic testing, the purity of the eugenol epoxy prepared in this embodiment is more than 99%. The rate is 78%.

Embodiment 3

[0044] The preparation process is the same as that of Example 2, the only difference being that the process parameters of the second low-temperature recrystallization process are different from the first one, and the temperature is -20°C. Tested by nuclear magnetic resonance, the prepared eugenol epoxy has a purity of 99% and a yield of 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com