Intelligent supporting device for emergency safety of large smart city industrial building elevator

A technology for industrial buildings and support devices, applied in the directions of transportation, packaging, elevators, etc., can solve the problems of loosening of the support structure, the impact of the shock resistance of the support structure on the operation safety, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

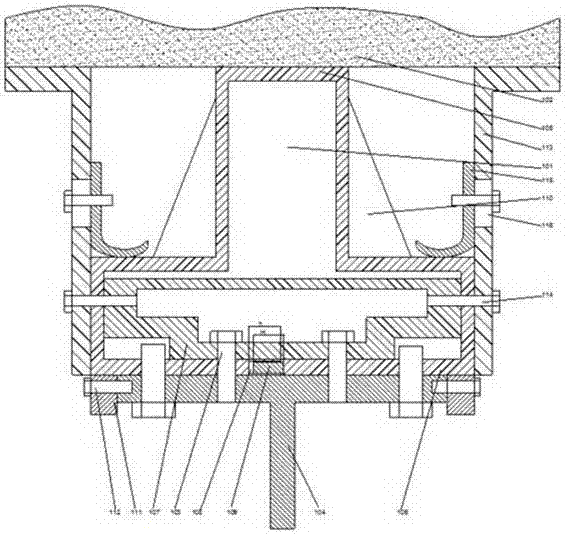

[0019] Such as figure 1 As shown, an intelligent support device for emergency safety of elevators in large-scale smart city industrial buildings includes a hollow support 101, the cross section of the support 101 is T-shaped, and one end of the T-shaped bottom 105 of the support 101 is fixed Connected to the elevator shaft wall 102, one end of the T-shaped top 106 is connected to the T-shaped guide rail 104 by bolts, the inner side of the T-shaped top 106 is provided with a connecting section 107, and the T-shaped top 106 is provided with a passage Holes, the first fixing bolt 103 passing through the connecting section 107 is provided on the connecting section 107, and the threaded hole corresponding to the position of the through hole is provided on the T-shaped guide rail 104, The first fixing bolt 103 passes through the connecting section 107 and the through hole on the T-shaped top 106 in turn and is screwed on the T-shaped guide rail 104, and on both sides of the bracket ...

Embodiment 2

[0022] This embodiment is based on Embodiment 1. In order to make the support structure have better impact resistance, in this embodiment, preferably, the middle part of the T-shaped top 106 is open, and the length direction of the opening is parallel to In the length direction of the bracket 101, a groove 108 is provided on one opening, and a positioning plate 109 is provided on the opposite opening, and the positioning plate 109 can be embedded in the groove 108, so The length H of the positioning plate 109 is less than or equal to the depth h of the groove 108 .

[0023]In this embodiment, in order to support the bracket, in this embodiment, preferably, a reinforcing rib 110 is provided on the side of the T-shaped top 106 away from the T-shaped guide rail 104, and the reinforcing rib 110 is One end of the rib 110 is connected to the T-shaped top 106 , and the other end of the reinforcing rib 110 is fixedly connected to the side wall of the T-shaped bottom 105 .

[0024] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com