Green and crisp plum automatic encasement mechanism

A technology for automatic packing and crispy plums, which is applied in the directions of packaging food, transportation and packaging, and types of packaged items. It can solve problems such as inability to guarantee stability and damage to crispy plums, improve packing quality, and reduce collision effects. , The effect of easy packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

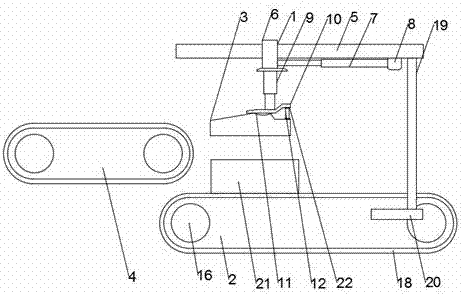

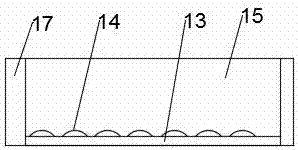

[0018] Such as figure 1 and figure 2 As shown, the present invention provides a kind of automatic boxing mechanism for green and crisp plums, comprising an adjustment frame 1, a transport platform 2, a loading plate 3 and a material delivery platform 4, and the bottom end of the adjustment frame 1 is connected to the loading plate 3 Together, the adjustment frame 1 is arranged on the top of the transport platform 2, and the position of the loading plate 3 is adjusted through the adjustment frame 1;

[0019] The adjustment frame 1 includes a cross bar 5, a sliding seat 6 and an electric push rod 7, one end of the electric push rod 7 is connected to the sliding seat 6, the sliding seat 6 is sleeved on the surface of the cross bar 5, and the electric push rod 7 is connected to the sliding seat 6. The other end of the push rod 7 is fixed by the fixing seat 8, the bottom end of the sliding seat 6 is connected with a hydraulic rod 9, and the bottom end of the hydraulic rod 9 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com