Large-stroke high-rigidity series-parallel hybrid machine tool with reconfigurable characteristic

A large-stroke, high-rigidity technology, applied in the field of serial-parallel hybrid machine tools, can solve problems such as the inability to meet the processing of large-scale special-shaped components, the processing requirements that are difficult to meet the precision, and the slow dynamic response speed of the output end, etc., to meet the processing tasks of free-form surfaces demand, high machining accuracy, and the effect of improving kinematics and dynamics performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A large-stroke, high-rigidity series-parallel machine tool with reconfigurable characteristics of the present invention is further described in detail with reference to the accompanying drawings and embodiments.

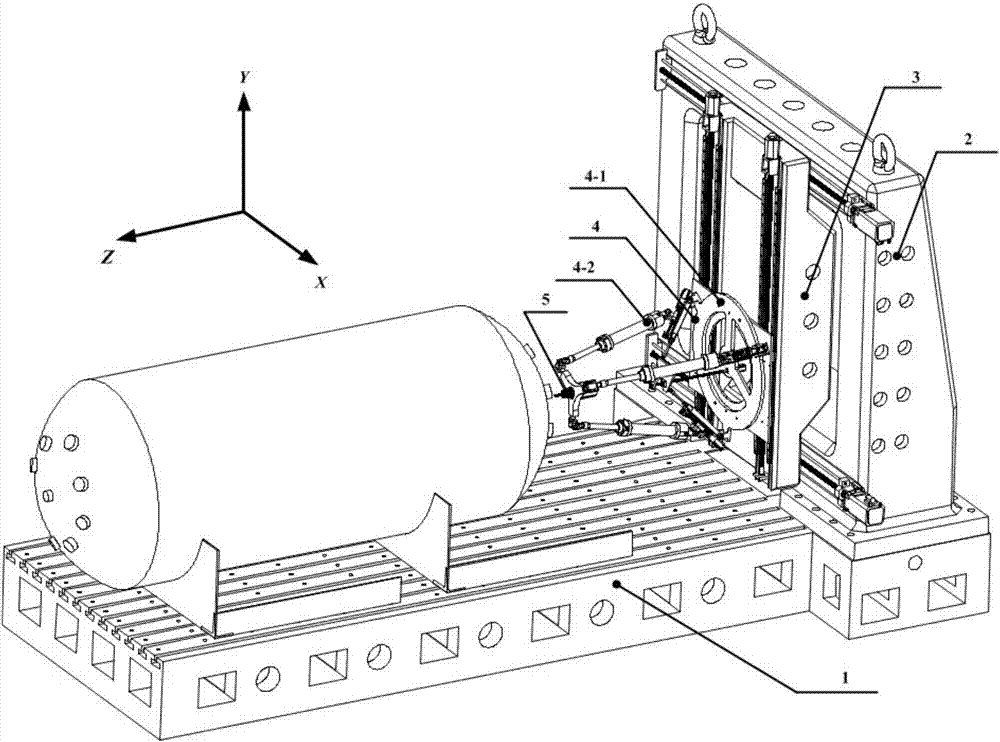

[0037] Such as figure 1 A schematic diagram of the overall structure of a reconfigurable large-stroke, high-rigidity series-parallel machine tool, which includes a fixed table 1, an X-direction moving unit assembly 2, a Y-direction moving unit assembly 3, and a lift adjustment device 4-1. Three driving branch chains 4-2 and the main shaft head 5 with the same structure connecting the moving platform and the lifting adjustment device 4-1.

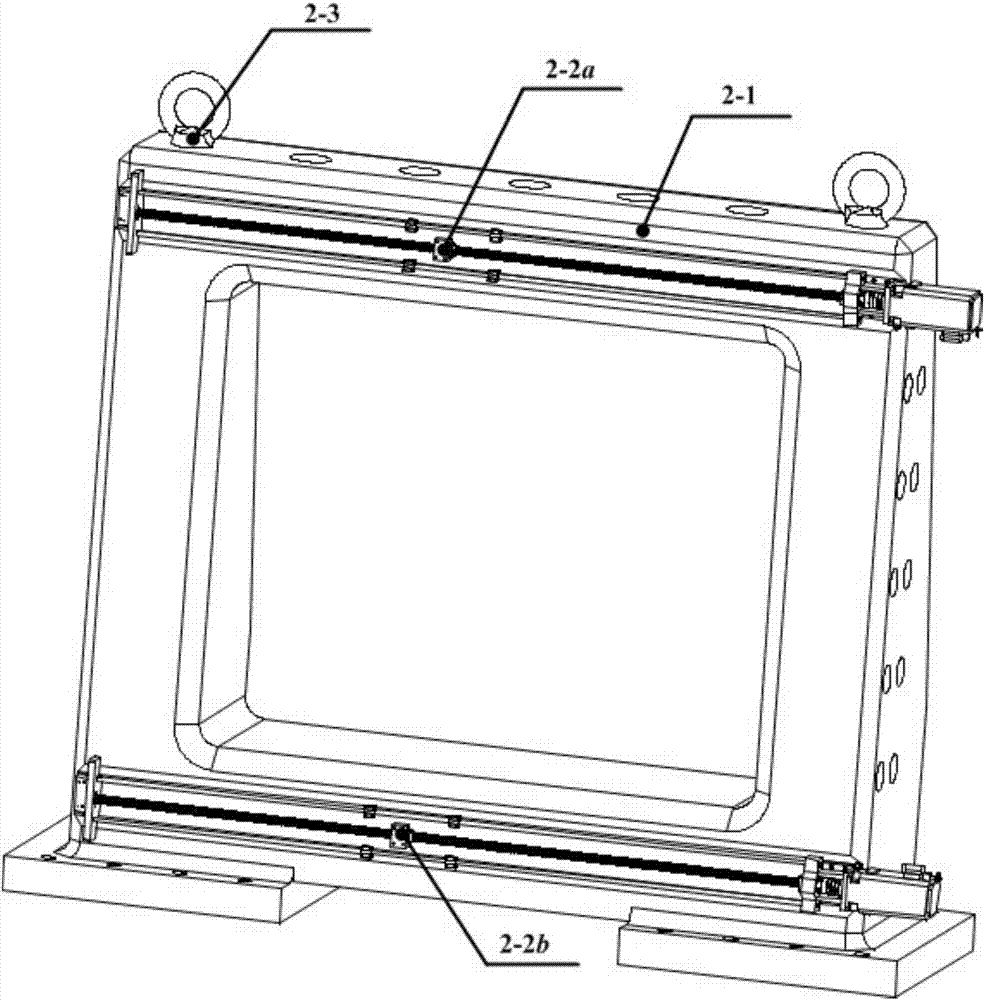

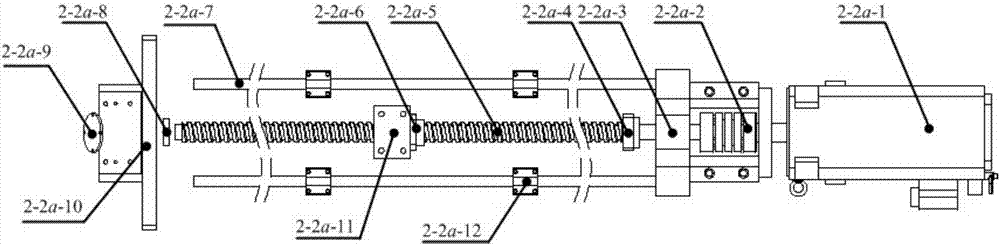

[0038] Such as figure 2 with 3 As shown, the fixed workbench 1 is equipped with a special fixture, and an X-direction "return" type mobile unit assembly 2 is arranged on the side of the fixed platform, and two The same ball screw drive unit 2-2a and 2-2b, wherein the ball screw drive unit 2-2a includes the servo motor 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com