A cooking machine processing method capable of displaying remaining processing time

A technology of processing time and processing method, applied in kitchen utensils, household utensils, applications, etc., can solve the problems of inaccurately displaying the remaining processing time, reducing the visibility and interactivity of cooking machines, and not being able to display the remaining processing time, etc. Achieve the effect of realizing visibility and interactivity, improving physical and mental health, and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

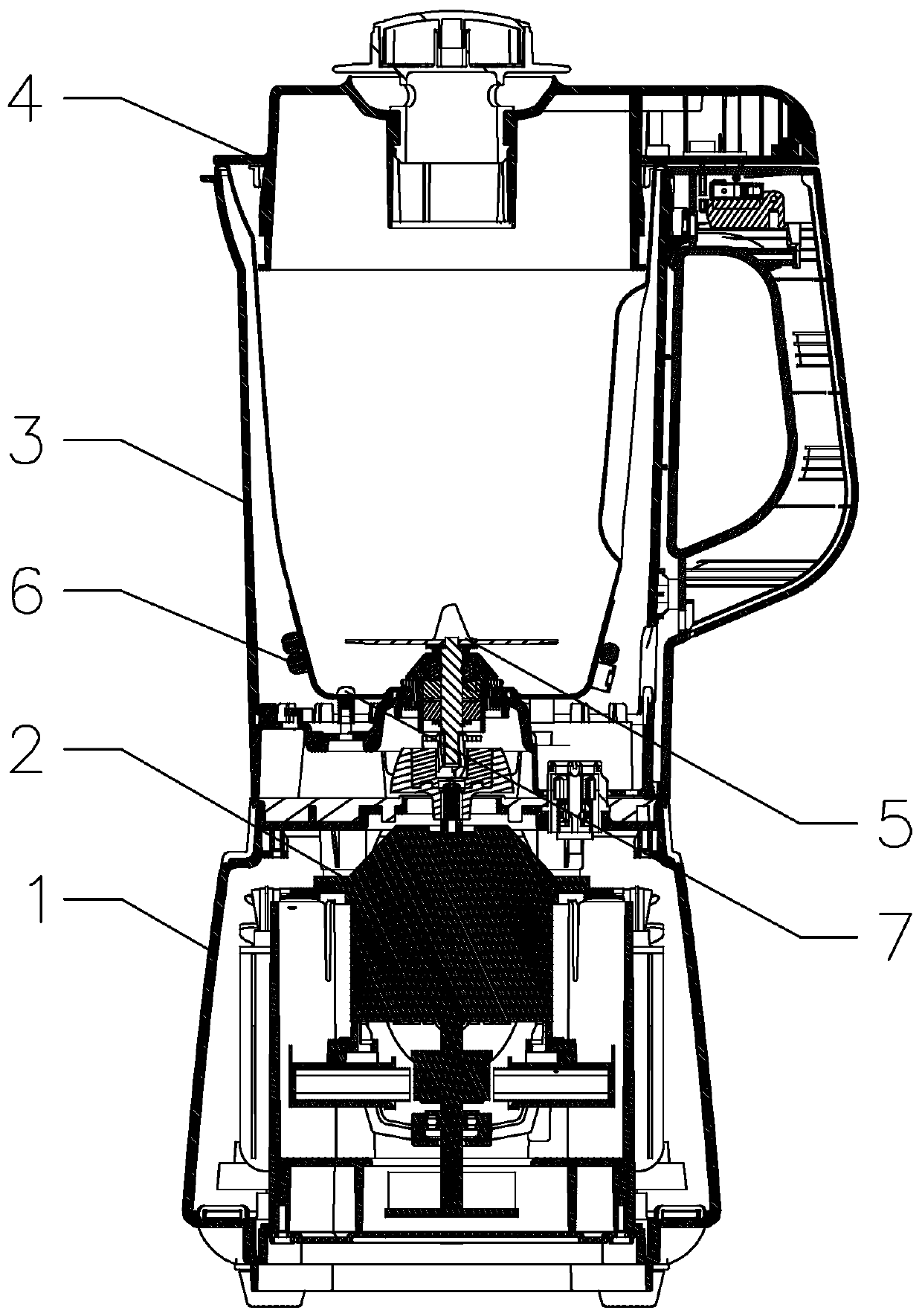

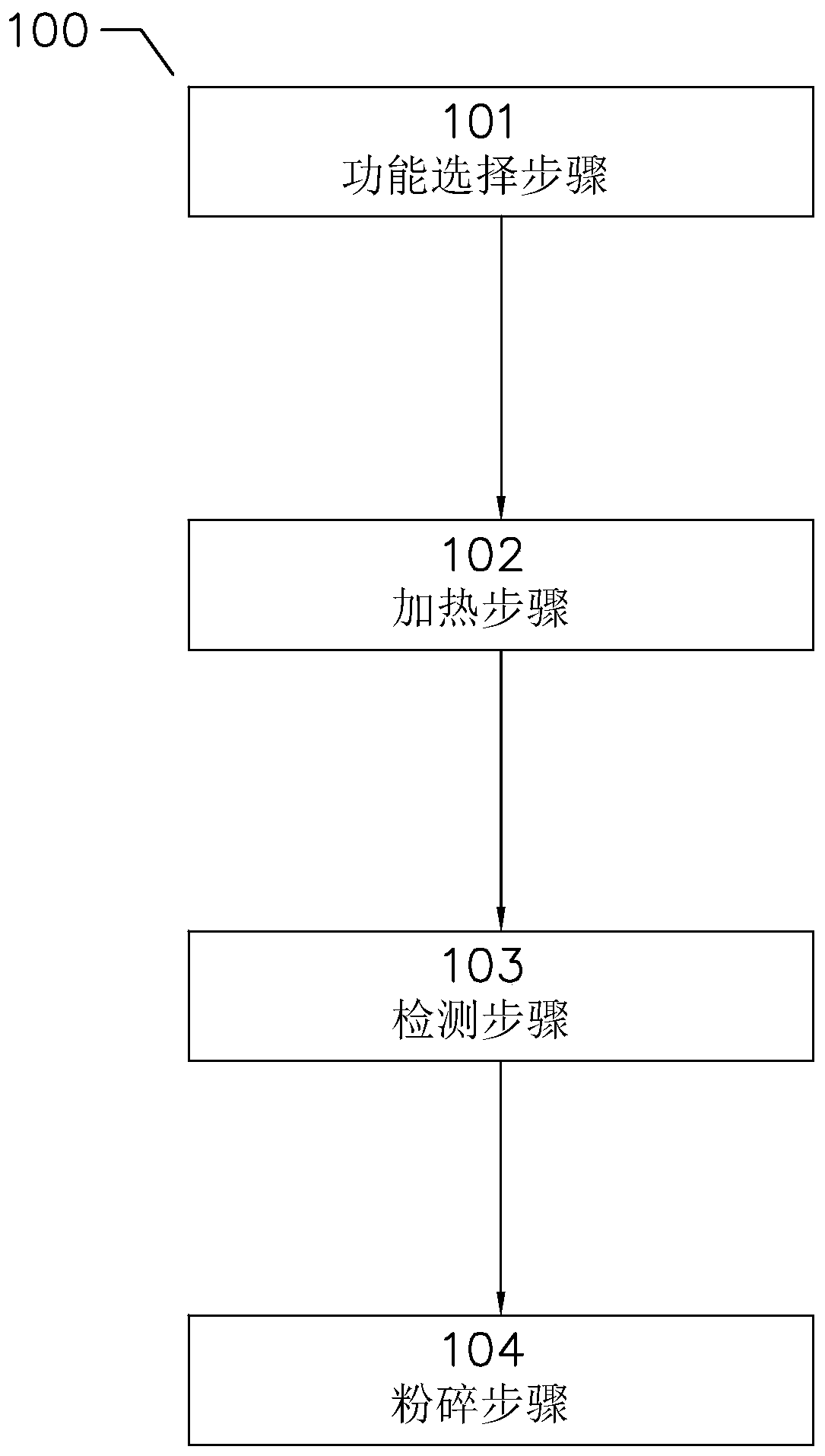

[0043] Such as figure 2 As shown, the present invention provides a cooking machine processing method that can display the remaining processing time, and the method includes the following steps:

[0044] Function selection step 101: After feeding, the control board receives the user's function selection instruction to start the corresponding processing program, and lights up the display element so that the display element displays the corresponding total processing time;

[0045] Heating step 102: the heating device heats the material in the cup to boiling;

[0046] Detection step 103: the temperature detection device obtains the temperature of the material in the cup and transmits it to the control board, and the control board sends different control signals to the display element according to the different temperature of the material in the cup obtained by the temperature detection device, and the display element uses different control signals to Update and display the actu...

Embodiment 2

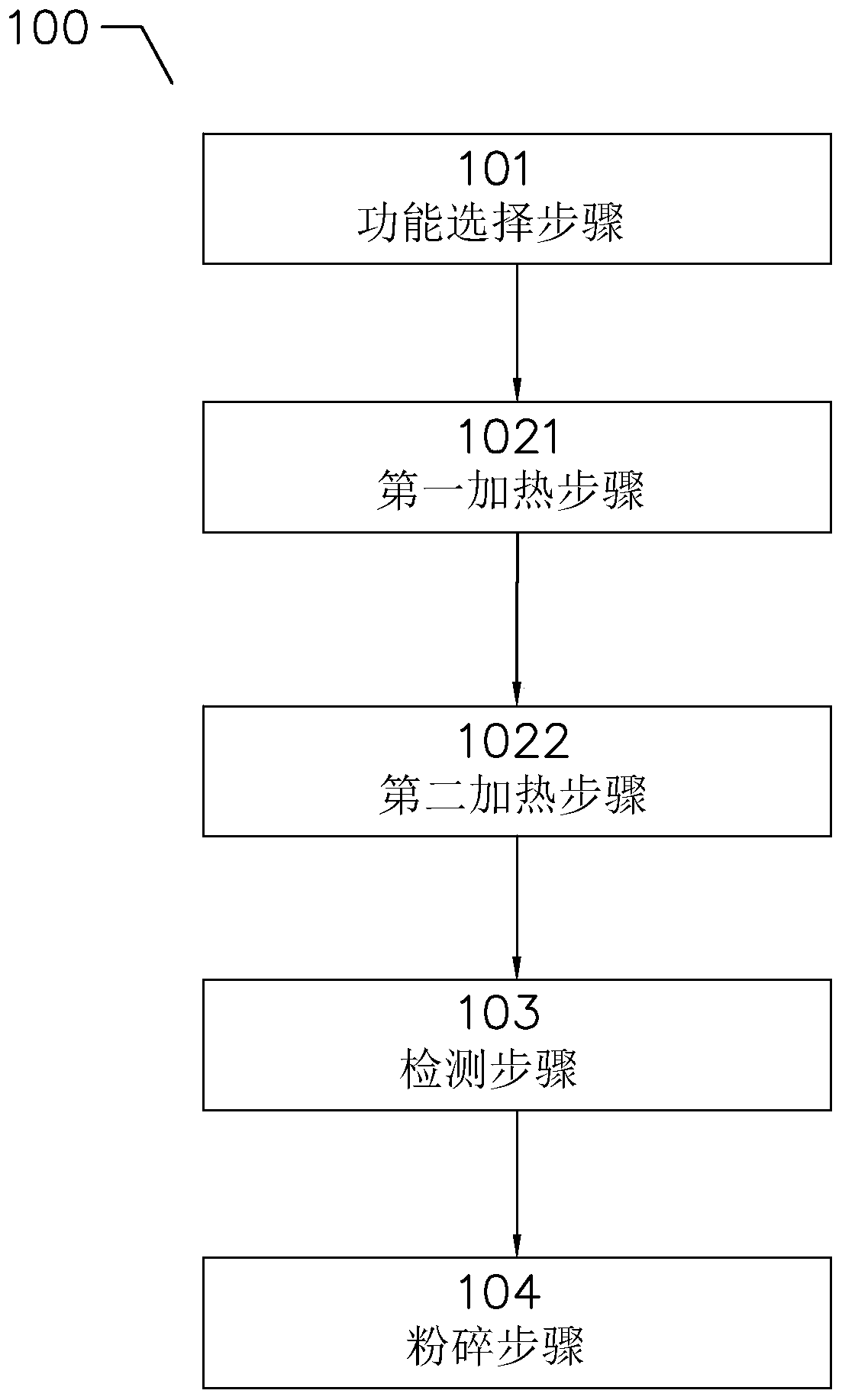

[0055] The difference between this embodiment and Embodiment 1 is that the heating step includes a first heating step and a second heating step.

[0056] In this example, if image 3 As shown, the cooking machine processing method 100 includes the following steps:

[0057] Function selection step 101: After feeding, the control board receives the user's function selection instruction to start the corresponding processing program, and lights up the display element so that the display element displays the corresponding total processing time;

[0058] The first heating step 1021: the heating device uses the first power P 1 Heat the material in the cup to temperature T;

[0059] The second heating step 1022: the heating device uses the second power P 2 Heat the material in the cup to boiling;

[0060] Detection step 103: the temperature detection device obtains the temperature of the material in the cup and transmits it to the control board, and the control board sends different...

Embodiment 3

[0067] The difference between this embodiment and the second embodiment is that the crushing step includes intermittent crushing steps.

[0068] In this example, if Figure 4 As shown, the cooking machine processing method 100 includes the following steps:

[0069] Function selection step 101: After feeding, the control board receives the user's function selection instruction to start the corresponding processing program, and lights up the display element so that the display element displays the corresponding total processing time;

[0070] The first heating step 1021: the heating device uses the first power P 1 Heat the material in the cup to temperature T;

[0071] The second heating step 1022: the heating device uses the second power P 2 Heat the material in the cup to boiling;

[0072] Detection step 103: the temperature detection device obtains the temperature of the material in the cup and transmits it to the control board, and the control board sends different contr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap