Power distribution cabinet internal dedusting device

A technology for dust removal devices and power distribution cabinets, which can be applied to substation/distribution device enclosures, smoke removal, substation/switch layout details, etc., and can solve the problems of time-consuming and laborious, low dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

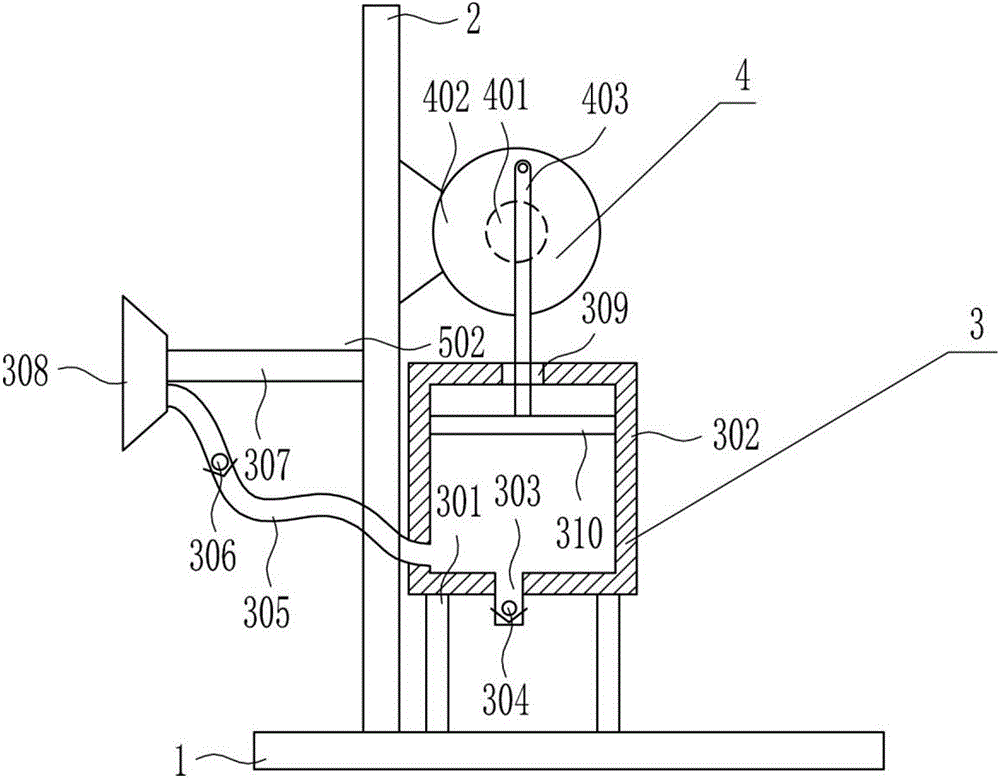

[0035] A dust removal device inside a power distribution cabinet, such as Figure 1-5 As shown, it includes a base plate 1, a support plate 2, a dust removal device 3 and a driving device 4. The left side of the top of the base plate 1 is vertically provided with a support plate 2, and the top of the base plate 1 on the right side of the support plate 2 is provided with a dust removal device 3. The dust removal part of the device 3 is located on the left side of the support plate 2, and the upper right side of the support plate 2 is provided with a driving device 4.

Embodiment 2

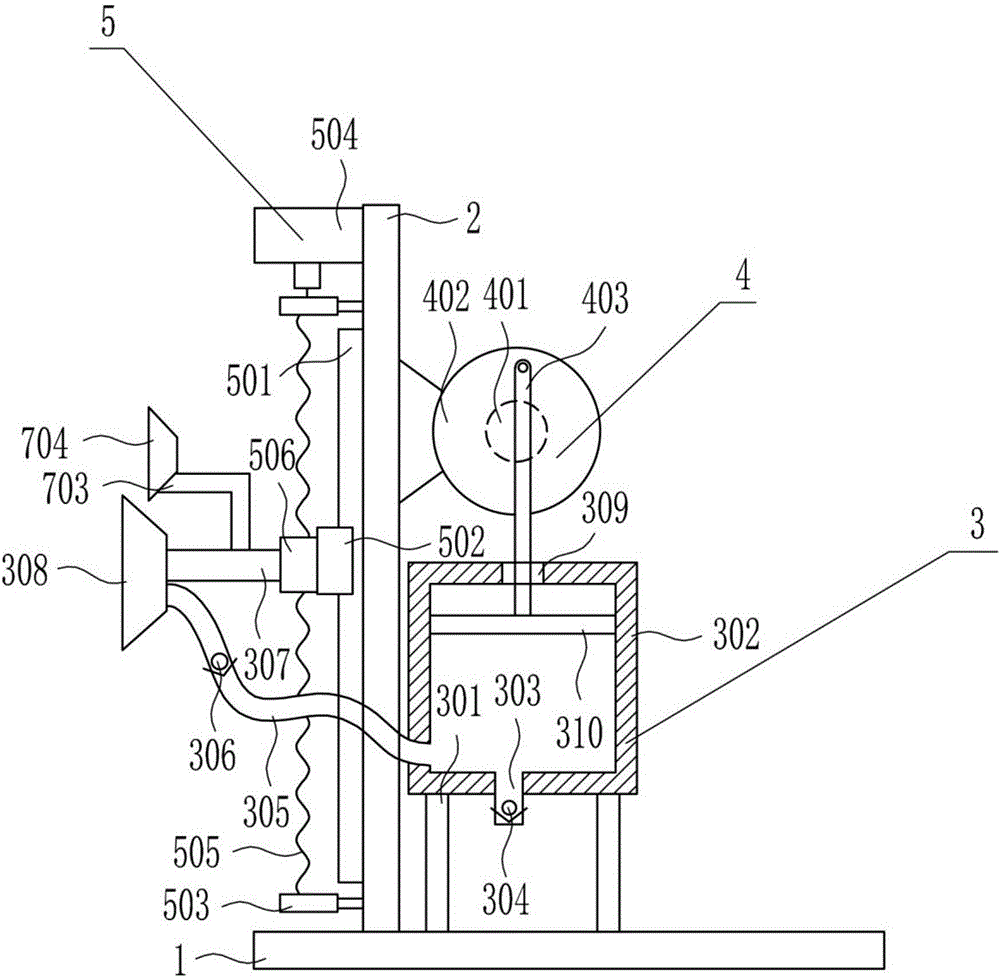

[0037] A dust removal device inside a power distribution cabinet, such as Figure 1-5 As shown, it includes a base plate 1, a support plate 2, a dust removal device 3 and a driving device 4. The left side of the top of the base plate 1 is vertically provided with a support plate 2, and the top of the base plate 1 on the right side of the support plate 2 is provided with a dust removal device 3. The dust removal part of the device 3 is located on the left side of the support plate 2, and the upper right side of the support plate 2 is provided with a driving device 4.

[0038] The dust removal device 3 includes a support rod 301, a compression box 302, an air inlet pipe 303, a first one-way valve 304, an air outlet pipe 305, a second one-way valve 306, a cross bar 307, an air spray nozzle 308 and a piston 310, and the support rod 301 is designed There are two, two poles 301 are left and right symmetrical, the bottom of the poles 301 is connected with the top of the bottom plate ...

Embodiment 3

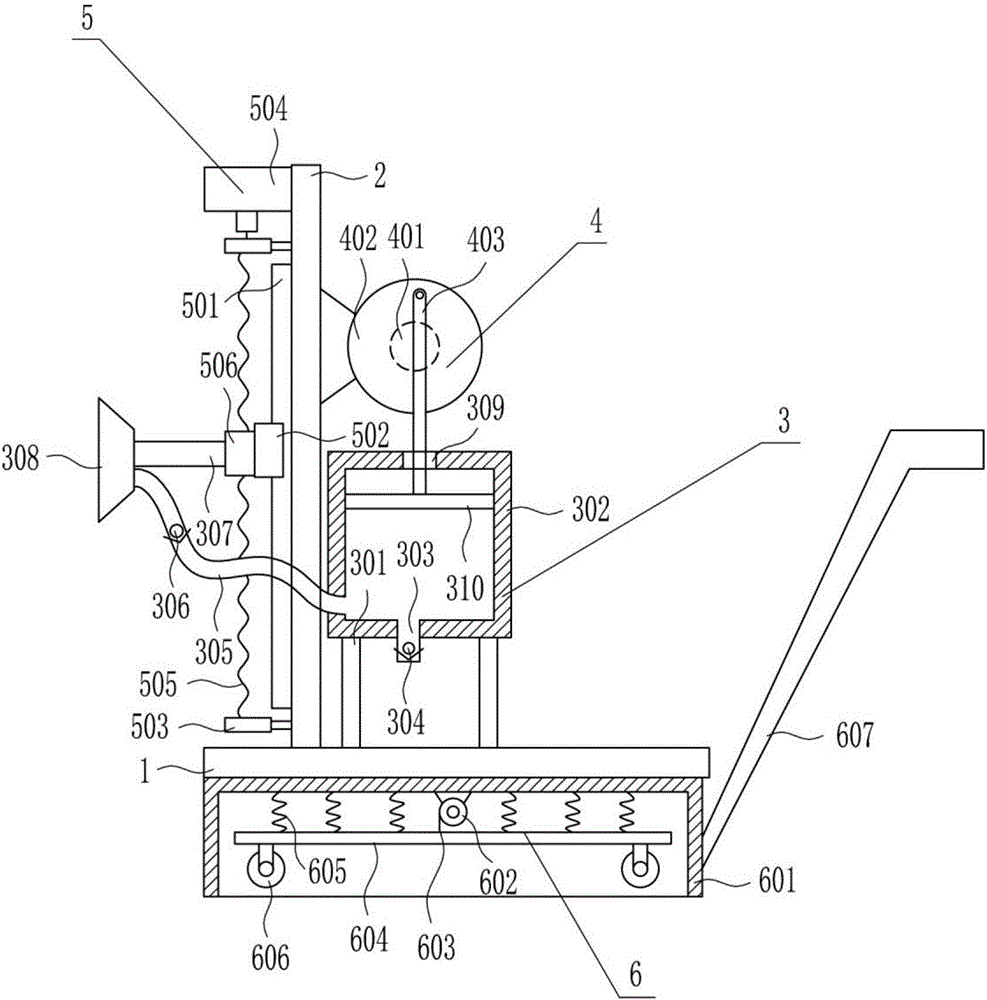

[0040] A dust removal device inside a power distribution cabinet, such as Figure 1-5 As shown, it includes a base plate 1, a support plate 2, a dust removal device 3 and a driving device 4. The left side of the top of the base plate 1 is vertically provided with a support plate 2, and the top of the base plate 1 on the right side of the support plate 2 is provided with a dust removal device 3. The dust removal part of the device 3 is located on the left side of the support plate 2, and the upper right side of the support plate 2 is provided with a driving device 4.

[0041] The dust removal device 3 includes a support rod 301, a compression box 302, an air inlet pipe 303, a first one-way valve 304, an air outlet pipe 305, a second one-way valve 306, a cross bar 307, an air spray nozzle 308 and a piston 310, and the support rod 301 is designed There are two, two poles 301 are left and right symmetrical, the bottom of the poles 301 is connected with the top of the bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com