An uncompensated space blasting fault handling method

A fault handling method and non-compensated technology, which is applied in design optimization/simulation, instrumentation, informatics, etc., can solve the problem of large engineering volume, affecting normal mining progress and mine output, tunneling jumbo and medium-deep hole rock drilling jumbo Problems such as frequent transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

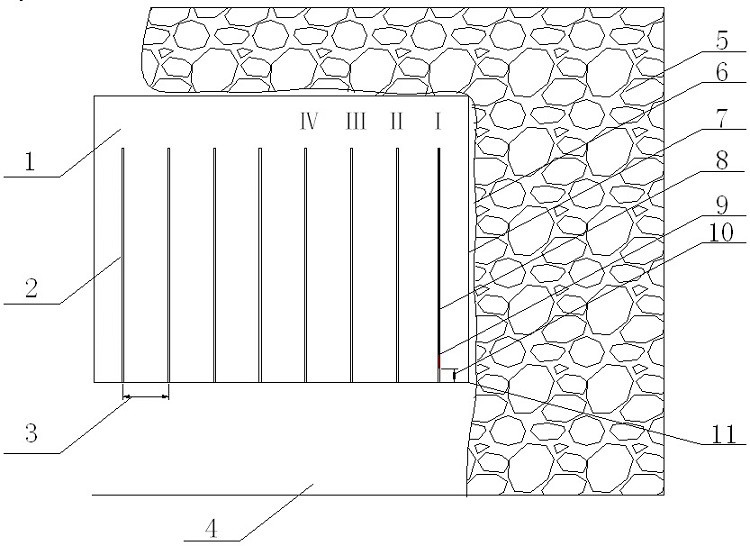

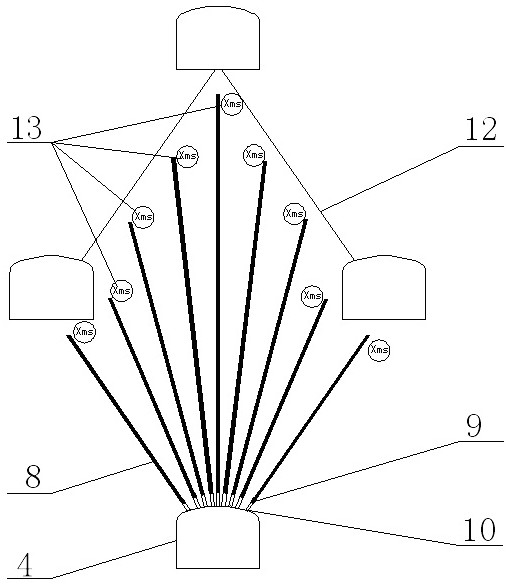

[0041] The traditional rock drilling and blasting parameters of iron ore are as follows:

[0042] Rock drilling: three-center rock drilling, 9 holes, 91mm blasthole diameter, 2.4m row spacing, linear meters and inclination angle of blastholes (l 1 = l 9 =11.7, Ф=60°; l 2 = l 8 = 12.8, Ф = 70°; l 3 = l 7 =18.0, Ф=78°; l 4 = l 6 =21.0, Ф=85°; l 5 =24.0, Ф=90°).

[0043] Blasting: emulsified granular ammonium oil explosives, Aurikai high-precision detonator detonator, ore-breaking step distance 2.4m, hole-bottom distance 2.3-2.8m, charge density ρ=1.0g / cm 3 .

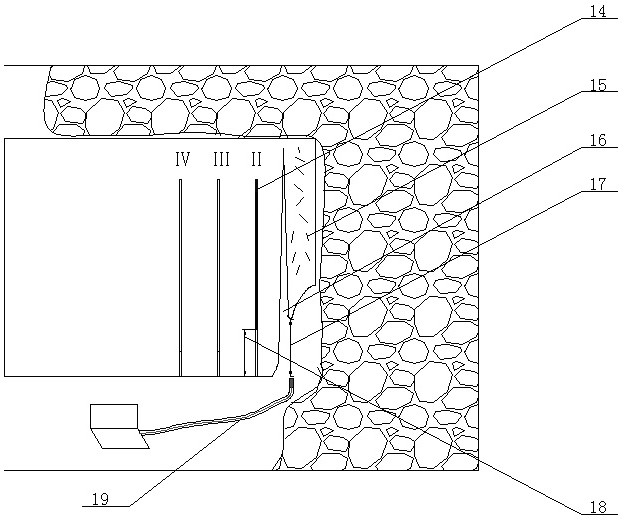

[0044] According to the downhole production and operation situation, the present invention is further clarified in combination with the application practice of field rock drilling and blasting parameters, the accompanying drawings and specific implementation methods.

[0045] ① Calculation and optimization of charge parameters of fan-shaped blast holes in the first row.

[0046] Detonation method: orifice detona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com