Method for treating sewage through adoption of QTCNP technology

A sewage and process technology, applied in the field of high-efficiency biological removal of sewage treatment, can solve problems such as reduction, and achieve the effects of simple process control, shortened process, and long sludge age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] The treated raw water is drawn from the actual sewage collection tank. The influent part of the sewage treatment plant is domestic sewage, and the other part is industrial sewage, which does not need to add other nutrients.

[0137] Influent water quality:

[0138] COD Cr = 525 mg / l;

[0139] NH 3 -N=56mg / l;

[0140] TN=62mg / l;

[0141] TP = 6.17mg / l;

[0142] pH 6.5

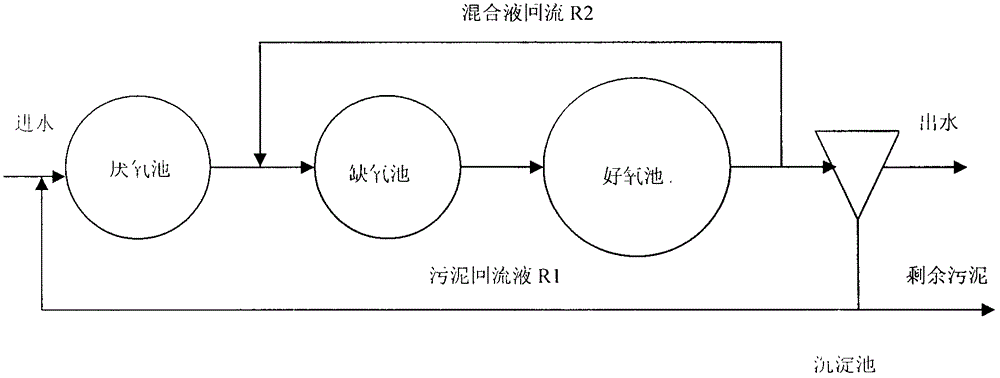

[0143] Actual control index: MLSS=6.67g / l, pH value of aerobic bioreactor 7.2, influent flow rate 0.4t / h, hydraulic retention time HRT=15 hours, biochemical tank DO: 2~4mg / l, mixed liquid reflux R 1 = 2.0, the sedimentation time of the sedimentation tank is controlled at 1.5 hours, and the sludge reflux ratio R 2 = 1.0, the mud age is controlled at 30 days.

[0144] Actual effluent water quality:

[0145] COD Cr = 18 mg / l;

[0146] NH 3 - N = 0.8 mg / l;

[0147] TN=8.2mg / l;

[0148] TP = 0.16mg / l;

[0149] The effluent reaches the first-class A standard of the new Beijing standard.

Embodiment 2

[0151] The treated raw water is drawn from the actual sewage collection tank. The influent part of the sewage treatment plant is domestic sewage, and the other part is industrial sewage, which does not need to add other nutrients.

[0152] Influent water quality:

[0153] COD Cr =712 mg / l;

[0154] NH 3 -N=74mg / l;

[0155] TN=86mg / l;

[0156] TP = 7.45mg / l;

[0157] pH 6.5

[0158] Actual control index: MLSS=5.56g / l, pH value of aerobic bioreactor 7.3, influent flow rate 0.5t / h, hydraulic retention time HRT=12 hours, biochemical tank DO: 2~4mg / l, mixed liquid reflux R1 = 2.0, the sedimentation time of the sedimentation tank is controlled at 1.5 hours, and the sludge reflux ratio R 2 = 1.0, the mud age is controlled at 35 days.

[0159] Actual effluent water quality:

[0160] COD Cr = 15mg / l;

[0161] NH 3 - N = 0.7 mg / l;

[0162] TN=7.6mg / l;

[0163] TP = 0.17mg / l;

[0164] The effluent reaches the first-class A standard of the new Beijing standard.

Embodiment 3

[0166] The treated raw water is drawn from the actual sewage collection tank. The influent part of the sewage treatment plant is domestic sewage, and the other part is industrial sewage, which does not need to add other nutrients.

[0167] Influent water quality:

[0168] COD Cr = 328 mg / l;

[0169] NH 3 -N=48mg / l;

[0170] TN=54mg / l;

[0171] TP = 4.54mg / l;

[0172] pH 6.9

[0173] Actual control index: MLSS=5.55g / l, pH value of aerobic bioreactor 7.5, influent flow rate 0.5t / h, hydraulic retention time HRT=12 hours, biochemical tank DO: 2~4mg / l, mixed liquid reflux R 1 = 3.0, the sedimentation time of the sedimentation tank is controlled at 1.5 hours, and the sludge reflux ratio R 2 =2.0, the mud age is controlled at 25 days.

[0174] Actual effluent water quality:

[0175] COD Cr = 8mg / l;

[0176] NH 3 - N = 0.5 mg / l;

[0177] TN=5.3mg / l;

[0178] TP = 0.09mg / l;

[0179] The effluent reaches the first-class A standard of the new Beijing standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com