pipe cleaning device

A technology for cleaning devices and pipes, used in water supply devices, waterway systems, transportation and packaging, etc., can solve problems such as high stress and failure, multiple winding times, large tension, etc., to achieve compact structure, avoid shortcomings, and excellent economy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

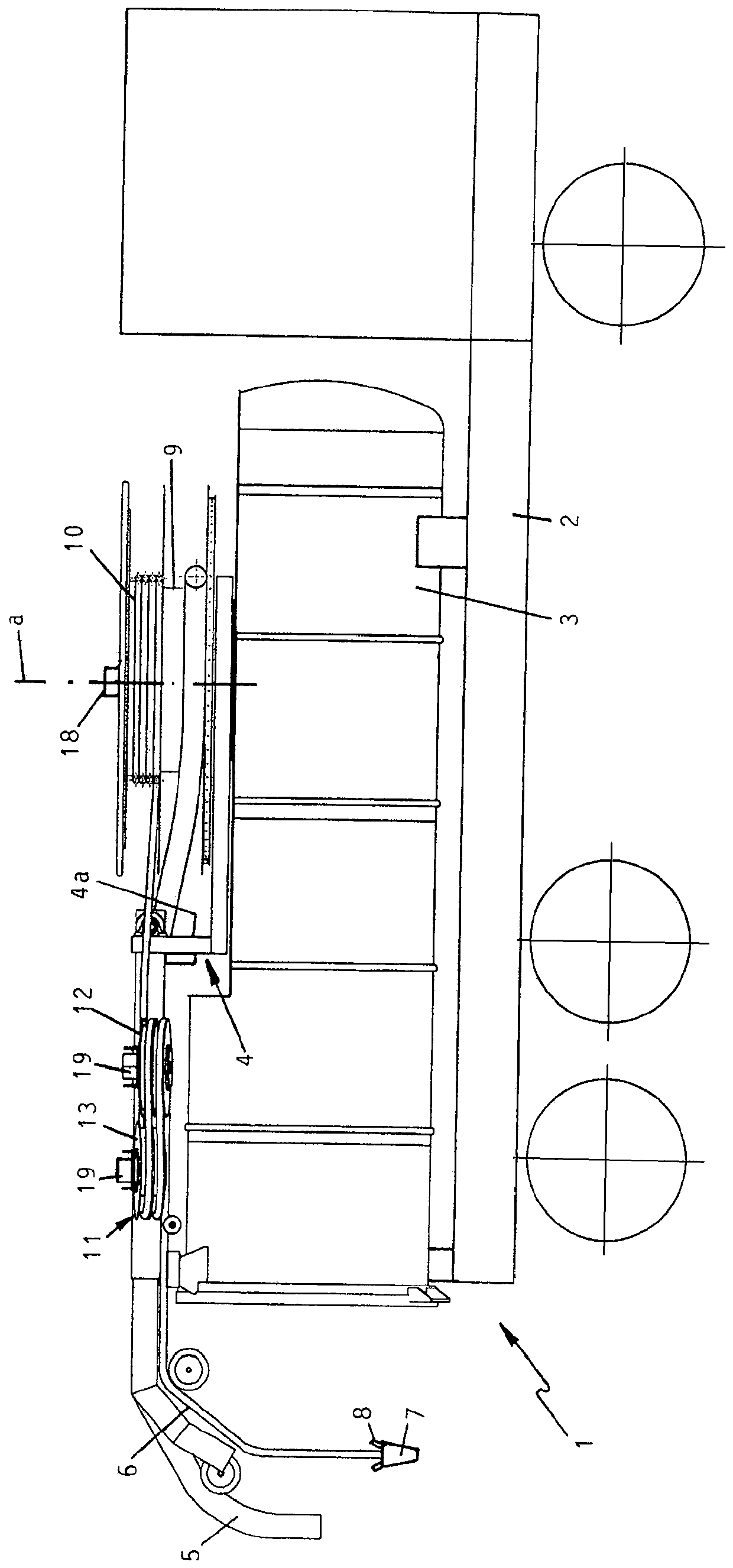

[0017] The main field of application of the invention is vehicles with a design designed as a pipe cleaning device, so-called pipe cleaning vehicles, the basic design and mode of operation of which are known.

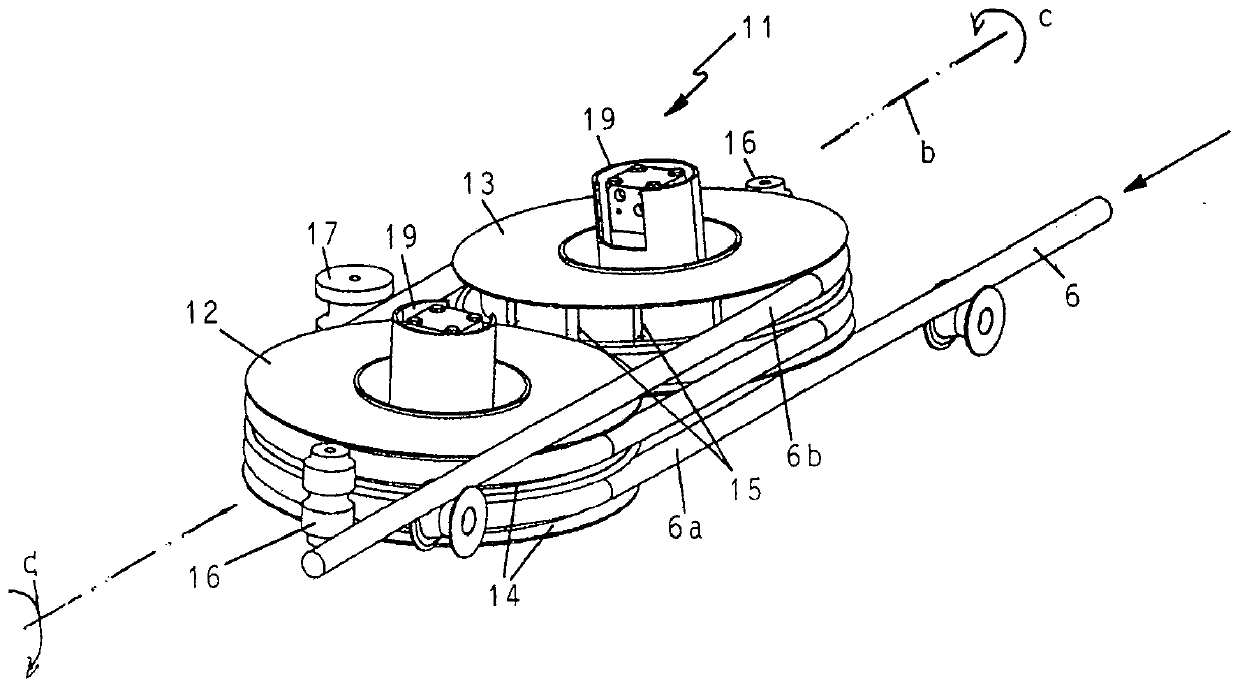

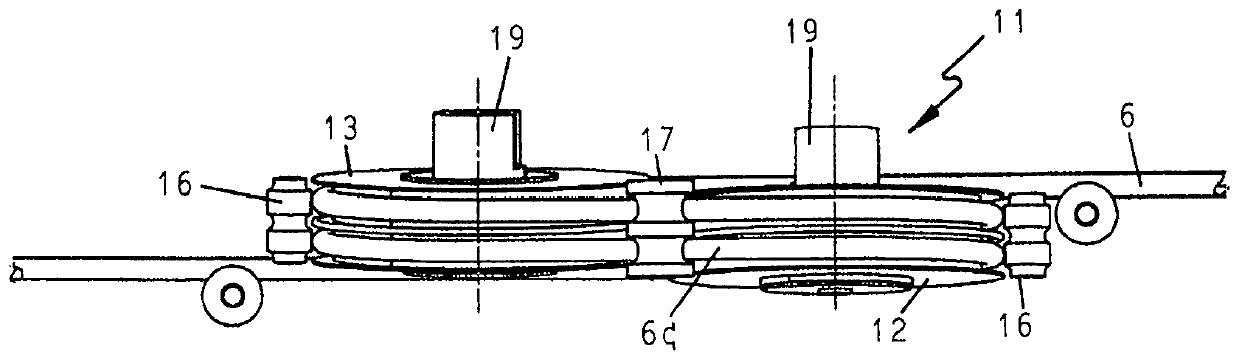

[0018] exist figure 1 The pipe cleaning vehicle 1 shown in contains a container 3, preferably in the form of a bucket, which is accommodated on the chassis 2 and has, not shown in detail, for the water required for cleaning the pipes and the water generated during the cleaning of the pipes. Cavity for mud sucked from the pipe. On this container 3 is accommodated a cantilever 4 which can be swiveled about a vertical axis a, a suction hose 5 which can be sunk into the pipeline, can be subjected to suction by means of a vacuum source not shown in detail, and can be introduced into the pipeline. The flushing hose 6, which can be loaded with high-pressure water, is unwound through the boom. For this purpose, the cantilever 4 can point downwards at the rear end in the form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com