Guiding vibration-isolating coupled seat for vehicle

A coupling, seat technology, applied in vehicle seats, vehicle parts, seat suspension devices, etc., can solve problems such as poor stability and reliability, complex suspension system structure, poor low-frequency vibration isolation effect, etc., to achieve high performance Stable, simple and compact structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Next, the guide-vibration-isolating coupling-type seat for vehicles according to the present invention will be further described by using a test prototype of the guide-vibration-isolating coupling type seat for vehicles.

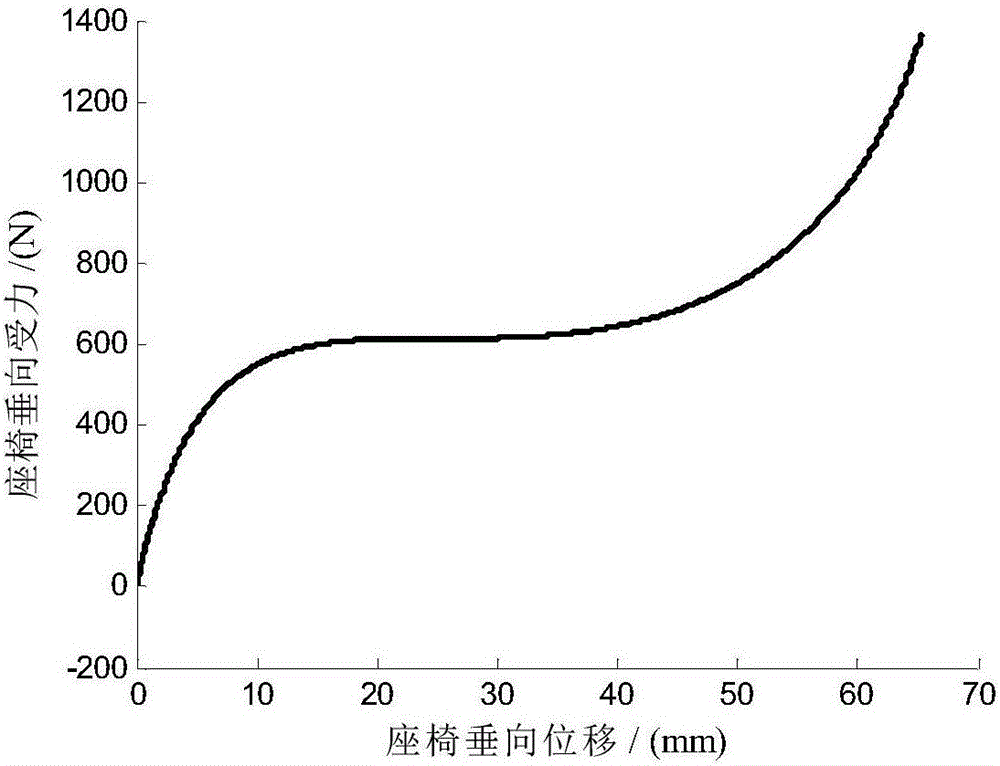

[0034] The structure of the test prototype of the guide-vibration-isolating coupling seat for vehicles is as described above. Among them, the ratio of the vertical static deflection of the seat under the rated load of the driver and the occupants to the length of the connecting rod 11 The angle θ=45° between the first guide rod 4 and the seat bottom plate 8, the length L of the first guide rod 4=600mm, the length r=40mm of the connecting rod 11; the equivalent vertical stiffness K of the main spring 7 at the static equilibrium position v =20N / mm, damping coefficient C of the shock absorber=500Nm / s.

[0035] In order to achieve the best low-frequency vibration isolation performance of the guided vibration isolation coupling seat for vehicles, accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com