Standard gripping device of pallet exchange system

A grabbing device and system standard technology, applied in the field of CNC machining automation, can solve problems such as difficulty in guaranteeing machining accuracy, high requirements on the stability of air source pressure, and inability to open the piston, so as to achieve simple and reliable overall structure and easy processing quality Guarantee and reduce the effect of running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings.

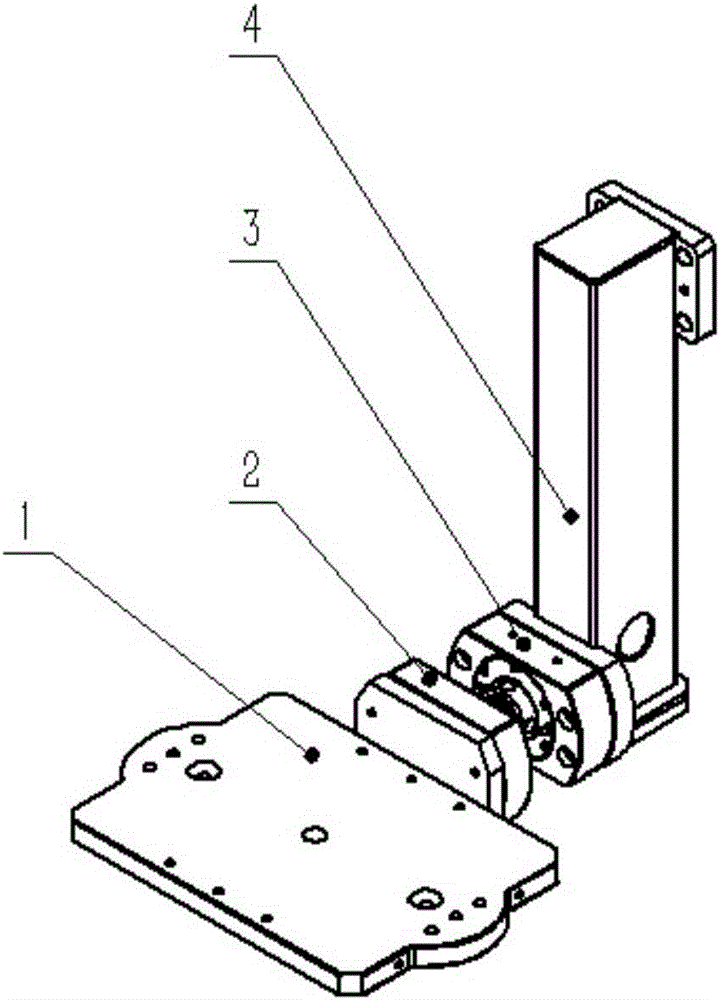

[0023] See figure 1 , The standard grabbing device of the pallet exchange system of the present invention is composed of a grabbing device main plate 3 and a grabbing device tool plate 2. The grabbing device main plate 3 is connected with the robot grabbing arm 4, and the grabbing device tool plate 2 is connected to the standard pallet. 1Connect.

[0024] See Figure 2-3 The main plate 3 of the grasping device of the present invention is mainly composed of a main plate base 6, a positioning cone pin 7, a robot connecting end cover 9, a ball cage 10, a ball 11, a cam 12, a screw 13, and a moving piston 14. There is a cavity inside the main disc substrate 6, and the moving piston 14 can move in the cavity. The end cover mounting portion 61 of the main disc substrate 6 and the robot connection end cover 9 are connected by screws, the robot connection end cover 9 and the main di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com