Transmission control device and transmission control method

A technology of control devices, control methods, applied in the direction of transmission control, elements with teeth, belts/chains/gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

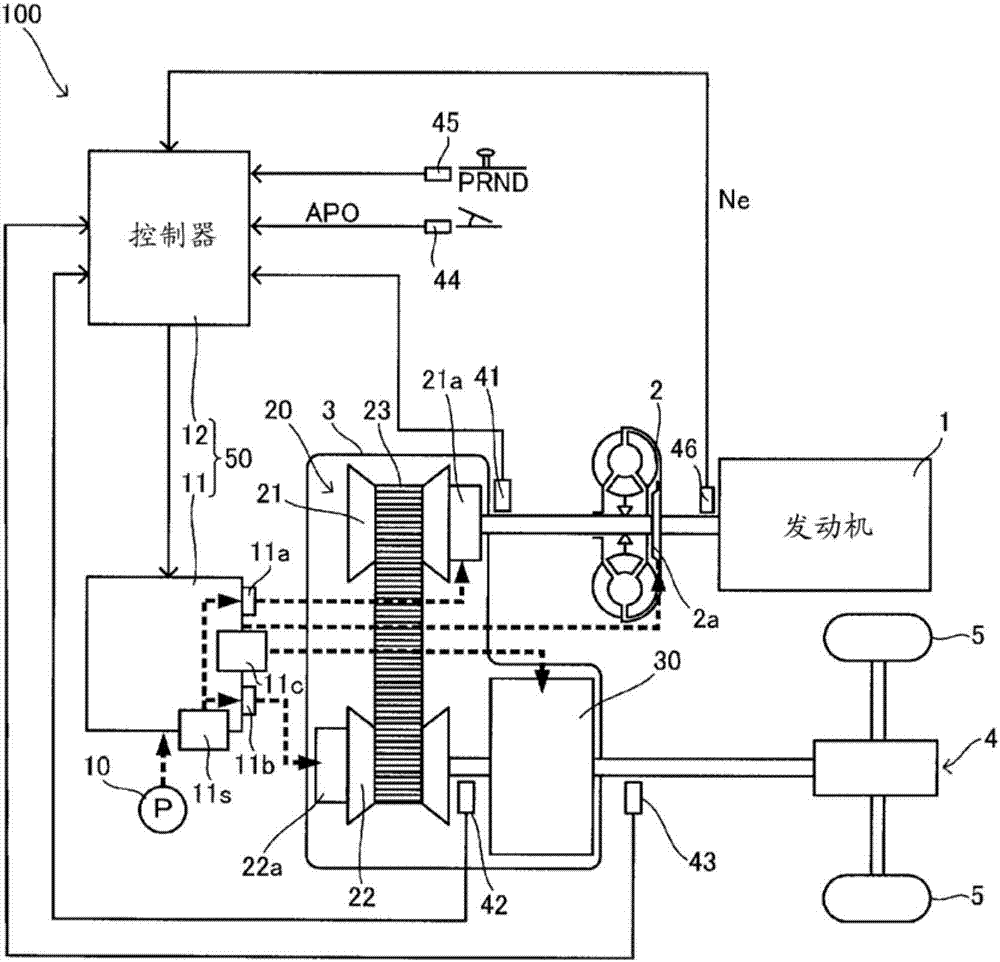

[0018] figure 1 It is a figure which shows the main part of the vehicle including the transmission 100. The vehicle includes an engine 1 , a torque converter 2 , a transmission mechanism 20 , an auxiliary transmission mechanism 30 , an axle 4 , and drive wheels 5 .

[0019] The engine 1 constitutes a power source of the vehicle. The torque converter 2 transmits power via fluid. In the torque converter 2, power transmission efficiency can be improved by engaging the lock-up clutch 2a. The transmission mechanism 20 and the subtransmission mechanism 30 output the input rotation speed at a rotation speed corresponding to the transmission ratio. The gear ratio is a value obtained by dividing the input rotation speed by the output rotation speed. The axle 4 is a drive axle constituted by a reduction gear or a differential. The motive power of the engine 1 is transmitted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com