Measuring system and measuring method for detecting variables on planetary carriers of a planetary gearing

A measurement system, planetary transmission technology, used in the testing of machine/structural components, the testing of mechanical components, the monitoring of wind turbines, etc., can solve problems such as adverse service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Although the invention has been illustrated and described in detail by means of preferred embodiments, the invention is not limited to the disclosed examples. A person skilled in the art can derive variants from this example without departing from the scope of protection of the present invention, as it is defined by the following claims.

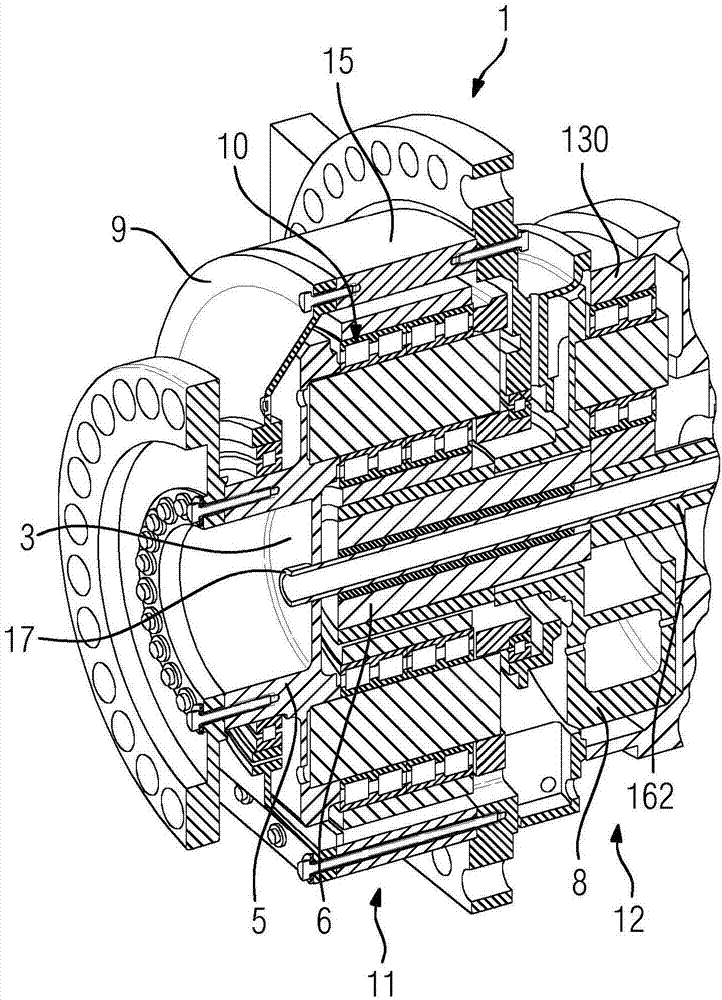

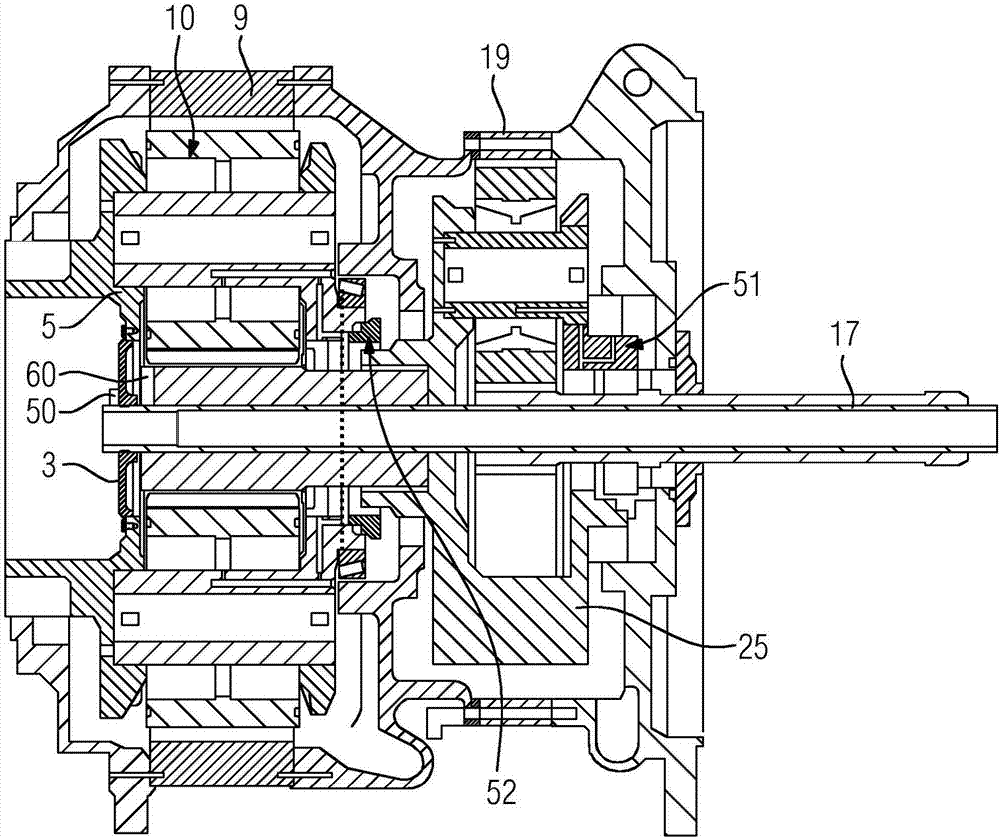

[0036] figure 1 A sectional view of a two-stage planetary gear 1 for use in a wind power plant is shown, which comprises a first planetary gear stage 11 on the drive side and a second planetary gear stage 12 on the output side. The output shaft of the transmission mechanism 11 is coupled with the generator. The sun shaft 6 of the first planetary gear stage 11 is coupled in a rotationally fixed manner to the planetary carrier 8 of the second planetary gear stage 12 .

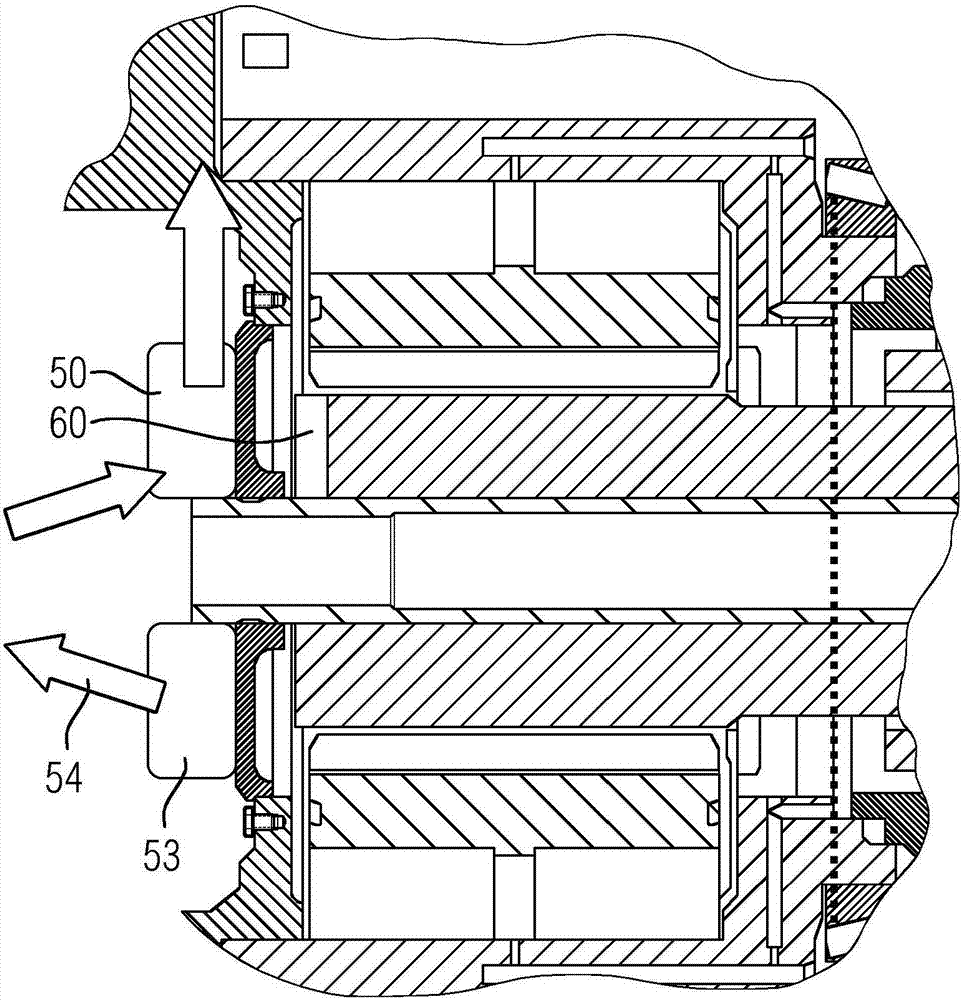

[0037] There are several rotating coordinate systems in planetary gear 1:

[0038] a) The transmission mechanism housing 9 and the ring gear 15 form a first coordinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com