Clip

A clip and component technology, applied in the direction of frictional clamping of detachable fasteners, thin plate connection, engine sealing, etc. The effect of absorbing board thickness dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

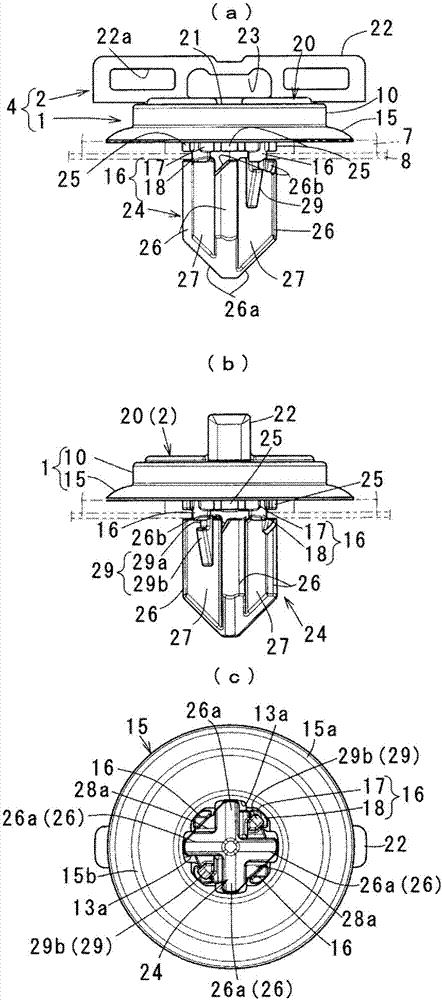

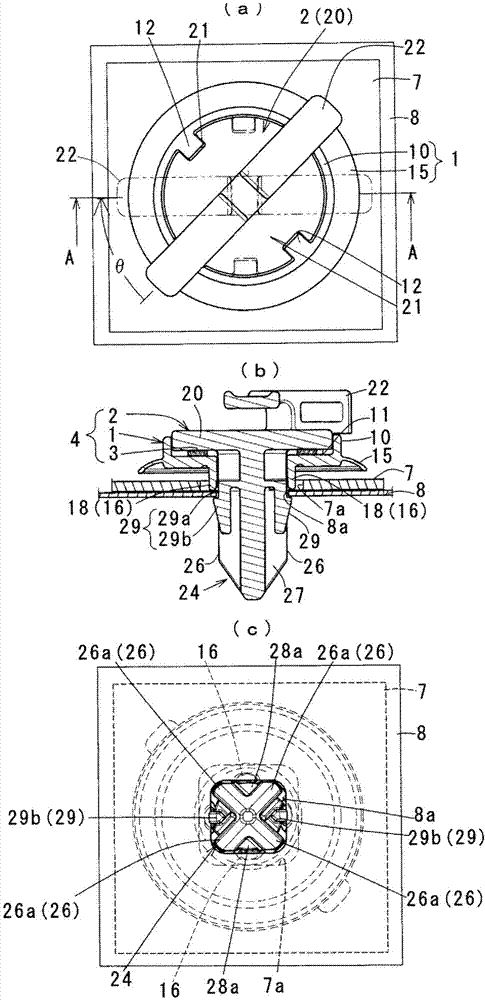

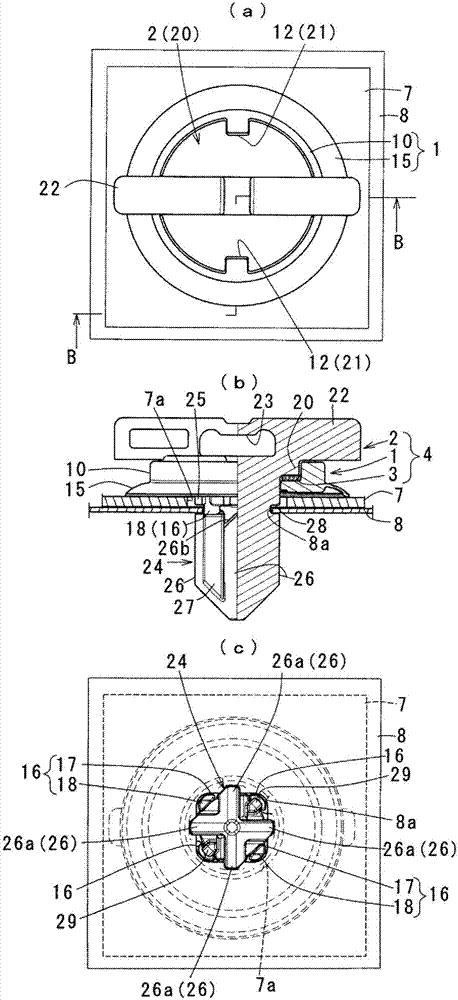

[0039] Hereinafter, embodiments and modifications of the present invention will be described with reference to the drawings. In this instruction, after describing the construction of the clip in detail, to make the assembly and main action clear, finally mentioned Figure 9 modification example.

[0040] (Structure) The clip 4 of the present embodiment is used in the case of detachably attaching one part 7 as a seal plate or the like to another part 8 such as a vehicle body or a panel, and is provided with a plug provided on the one part 7 and the other part 8 . The head 10 is arranged so as to form the through hole 7a of one member 7 among the through holes 7a, 8a of the member 8 , and the leg portion 24 is inserted into the through holes 7a, 8a and engaged with the back side of the other member 8 . That is, this clip 4 includes: a washer 1, which is a first member having a head 10, a suction cup portion 15 protruding around the head 10, and an insertion hole 13 for a leg; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com