Brush holder, brush holder structure, and brush motor

A brush motor and brush holder technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of inner hole size tolerance, easy deformation, large error, etc., to improve performance reliability and size controllability , not easy to deform the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

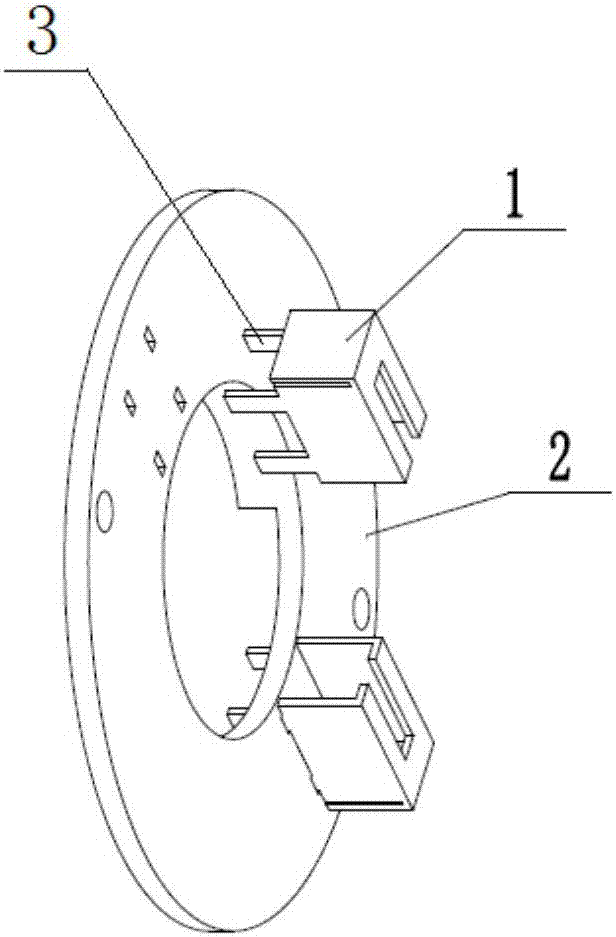

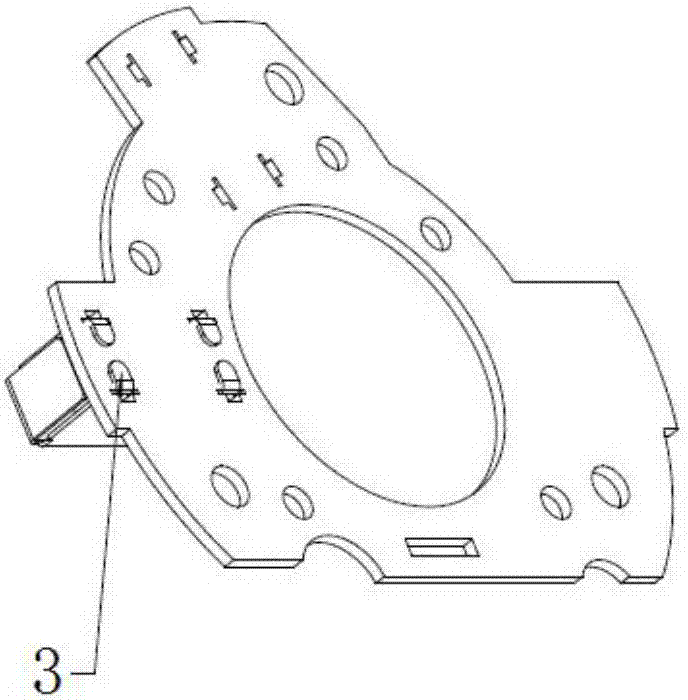

[0049] This embodiment provides a brush holder, such as Figure 4 to Figure 6 As shown, the brush holder 5 in this embodiment includes a brush holder body 51 and a brush holder cover 52 . The brush holding body 51 is provided with a brush accommodating hole 511 for accommodating the brush. The brush holder cover 52 is closed on the brush holder body 51 to prevent the brush from popping out of the brush accommodating hole 511 . Wherein, the brush holder body 51 is a molded part, and the brush holder cover 52 and the brush holder body 51 are a split structure.

[0050]The brush holder provided in this embodiment is formed by forming the brush holder body 51 by a mould, and the brush holder body 51 and the brush holder cover 52 are provided with a split structure, so that the brush holder body 51 is not easily deformed during transportation, and When forming the brush holder body 51, the brush accommodating hole 511 is obtained by demoulding a mold core, and there is no influen...

Embodiment 2

[0052] Preferably, this embodiment provides a brush holder, compared with the previous embodiment, such as Figure 4 to Figure 6 As shown, the brush handle cover 52 in this embodiment is engaged with the brush handle body 51 . Specifically, the brush handle cover 52 and the brush handle body 51 are engaged and connected through an engaging structure.

[0053] In this embodiment, the brush holder cover 52 and the brush holder body 51 are engaged and connected, so that when assembling the brush holder body 51 and the brush holder cover 52, the brush holder provided in this embodiment does not need assembly tooling, and only needs to snap the two together. That is, the assembly speed of the brush holder, the brush holder structure and the brushed motor is improved, and the manufacturing cost of the brush holder, the brush holder structure and the brushed motor is reduced.

[0054] In this embodiment, there are several schemes for the snap-fit connection between the brush handl...

Embodiment 3

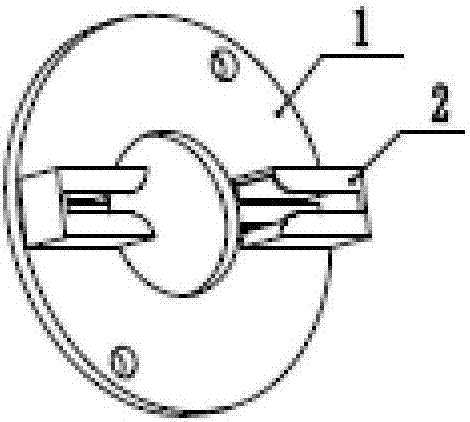

[0060] Preferably, this embodiment provides a brush holder, compared with Embodiment 2, such as Figure 4 to Figure 6 As shown, in this embodiment, the engaging connection mode of the brush holder body 51 and the brush holder cover 52 is specifically as follows: in the brush holder structure of this embodiment, the upper end of the brush holder body 51 is provided with an engaging member 512; A clamping hole 521 is opened; wherein, the engaging member 512 cooperates with the clamping hole 521 to cover the brush handle cover 52 on the brush handle body 51 . On this basis, this embodiment further designs the engaging part 512 and the locking hole 521 as follows:

[0061] Such as Figure 5 As shown, the locking hole 521 is configured as a through hole passing through the brush handle cover 52 . Correspondingly, as Figure 4 , Figure 6 to Figure 9 As shown, the engaging member 512 in this embodiment includes a first portion 5122 and a second portion 5121 . Wherein, the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com