Degaussing cable trough, laying device for ship cable and cable laying method

A technology for cable troughs and ships, used in cable laying equipment, electrical components, etc., can solve the risk of the whole ship's anti-sinking performance and vitality, the overall sealing performance of degaussing cable pipes is difficult to ensure, and it is difficult to convert box sealing The whole ship has the same life expectancy and other problems, to achieve the effect of facilitating cable laying work, reducing scratching damage, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

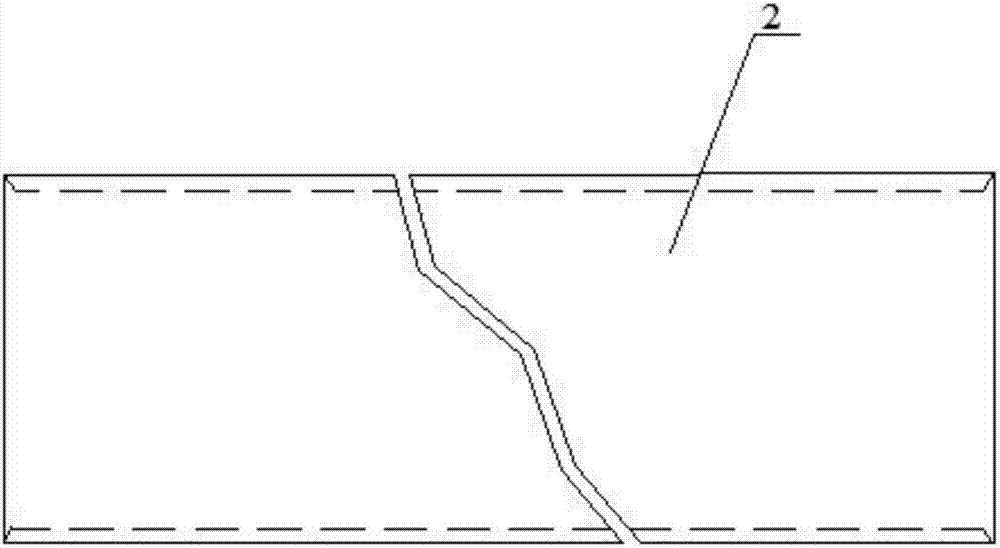

[0050] By laying the cable 1 in the cable trough body 2 of the present invention, the cable 1 laying work of the construction personnel can be greatly facilitated, and the scratch damage to the cable 1 can be reduced.

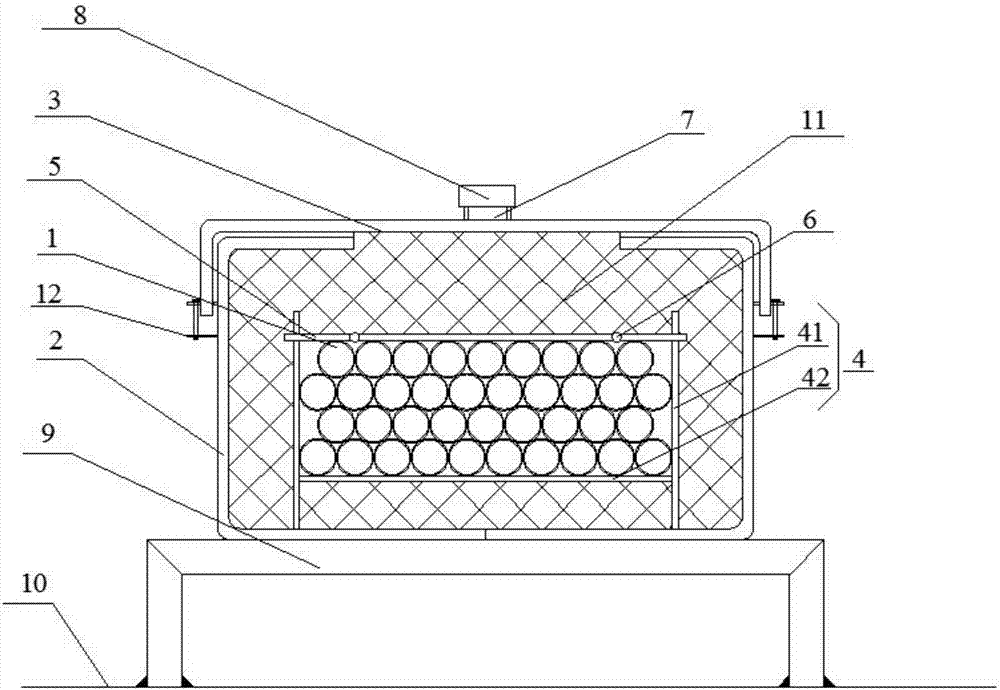

[0051] figure 1 It is a schematic cross-sectional view of a degaussing cable trough according to an embodiment of the present invention. See figure 1 , The embodiment of the present invention provides a degaussing cable trough, including:

[0052] Cable trough body 2, with a rectangular cross section and an open top, with a semi-open structure;

[0053] Cover plate 3, which covers the top opening of said cable trough body 2; and

[0054] The cable hook for fixing the cable 1 is built into the cable trough body 2. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com